Cotton fiber specific promoter and its use

A specific promoter and cotton fiber technology, applied in the field of plant genetic engineering, can solve problems that affect the accuracy of experimental results and experimental progress, and interfere with the normal growth of transgenic cotton

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

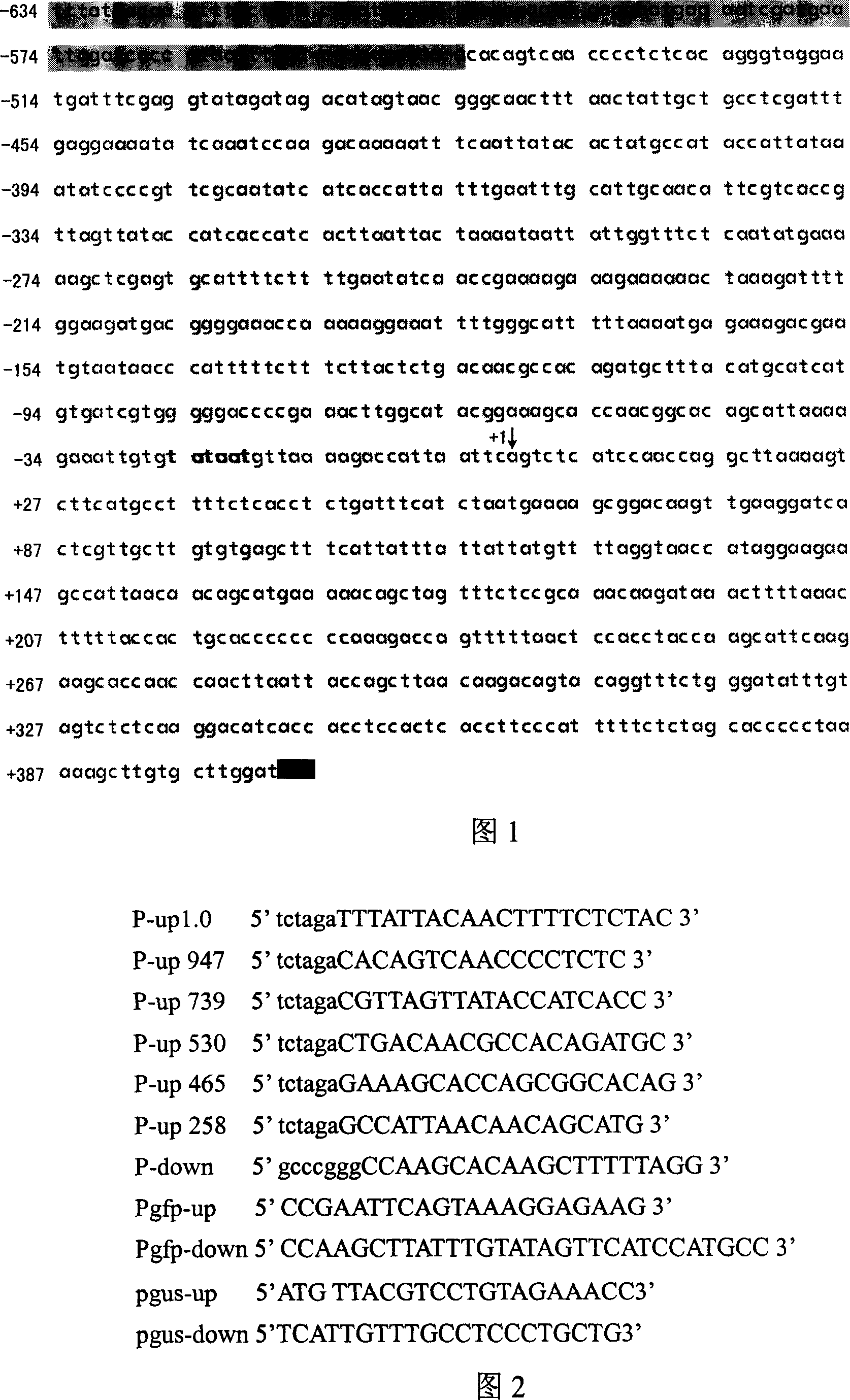

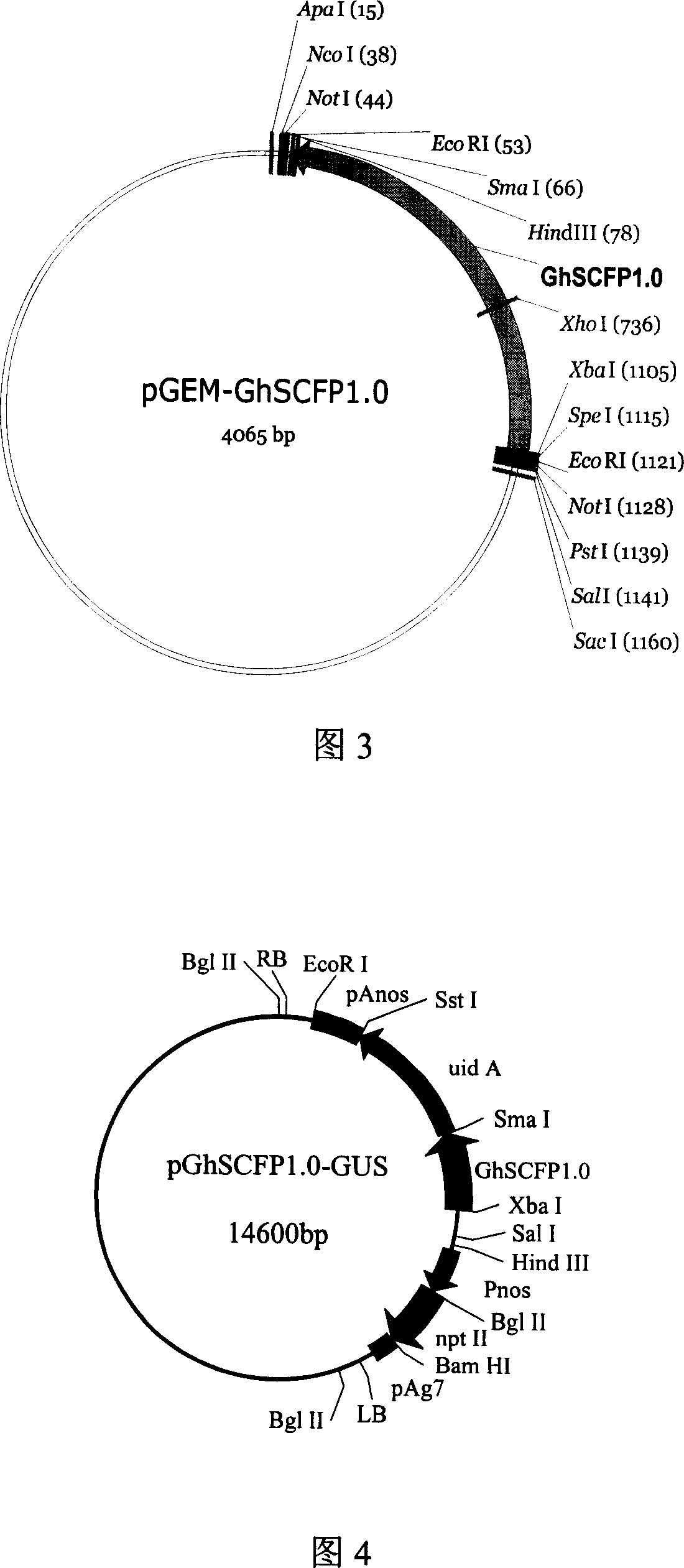

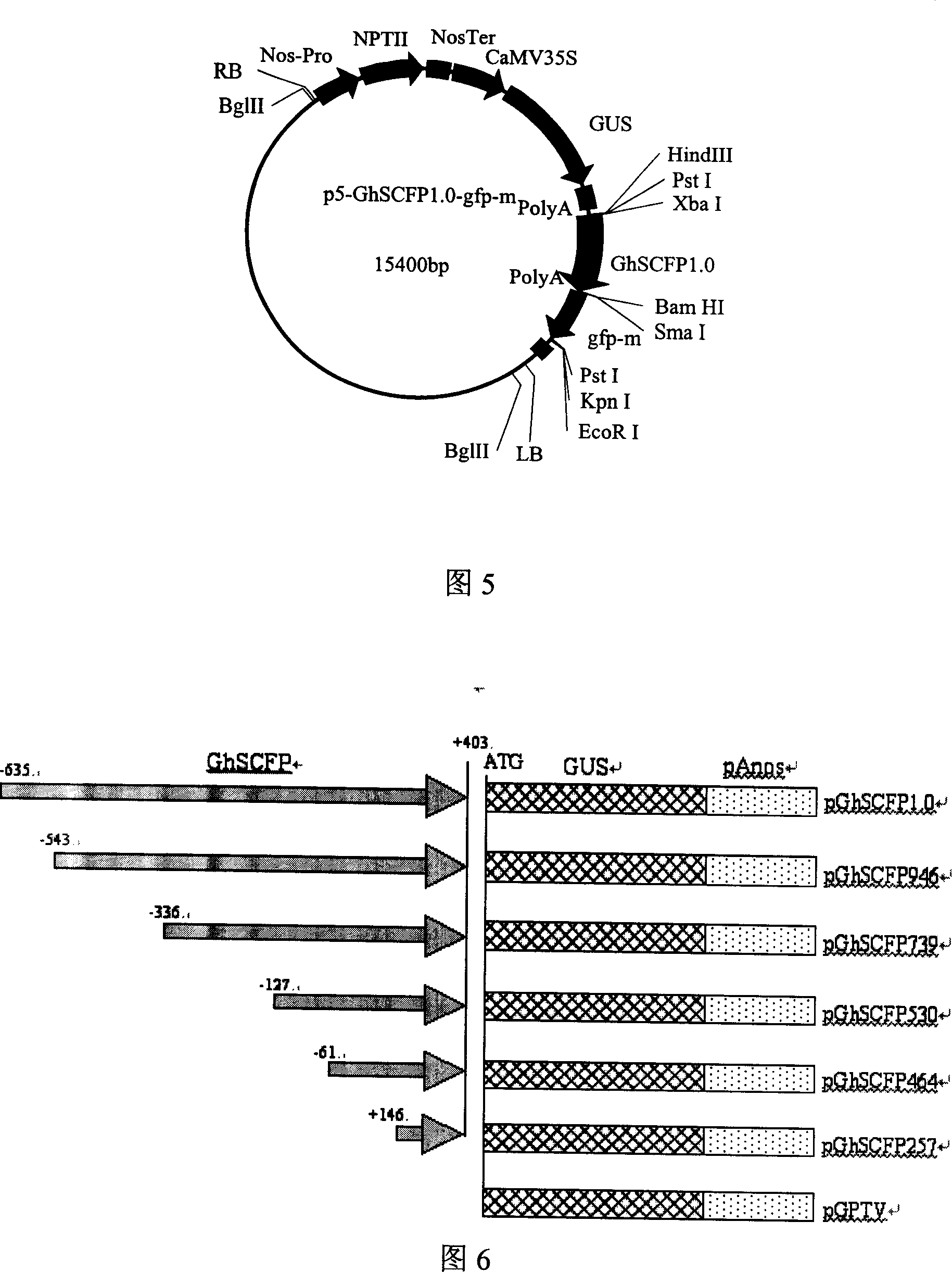

Method used

Image

Examples

Embodiment 1

[0041] [Example 1] Extraction of RNA from cotton fiber

[0042] Mark the cotton flowers on the day of flowering, and take the bolls from the day of flowering to 9 days after flowering. For the extraction of cotton ovule and fiber RNA, refer to the method of Chang Shujun et al. (Shujun Chang, Plant Molecular Biology Reporter 1993 11: 113-116), but some steps have been changed. The specific operation procedure is as follows: immediately place the cotton boll in the ice box after sampling In the room, the ovules and fibers on the day after flowering, and the fibers on the 6th and 8th days after flowering were respectively stripped, quickly ground into powder under liquid nitrogen and put into a 50ml centrifuge tube. Add 10ml 65°C preheated extraction buffer (CTAB 2%, PVP 2%, Tris-HCl 100mmol / L pH8.0, EDTA 25mmol / L, NaCl 2mol / L, Spermidine 0.5mg / ml), and mix well at 65°C Water bath for 3 minutes, then add an equal volume of chloroform: isoamyl alcohol (24:1), mix well and centrifuge: ...

Embodiment 2

[0043] [Example 2] Construction of cotton fiber cDNA library and gene cloning

[0044] The method of constructing cotton fiber cDNA library is mainly carried out according to the product manual of STRATAGENE. The brief description is that 100μg of cotton ovule and fiber on the day after flowering and the total RNA of the fiber at 6 and 8 days after flowering are reversed transcribed by GIBCO BRL Super-script II. The first strand of cDNA was synthesized by enzyme, and then STRATAGENE cDNA library construction kit (λZAP) was used to establish a cDNA library of cotton fiber. After determination, the titer of the primary library is 9.8×10 6 ; The titer of the amplified library is 1×10 11 . A total of 20 clones were randomly selected and subcloned into the plasmid pBSsk. The test showed that the length of the cloned foreign fragment was between 0.7-2.5 kb, which can meet the needs of gene cloning.

Embodiment 3

[0045] [Example 3] Isolation of cotton genomic DNA

[0046] Take about 1 gram of cotton leaf material, put it in a mortar, quickly grind into powder under liquid nitrogen, put it into a centrifuge tube and add 3ml of 65°C preheated CTAB extract, shake and mix quickly, and bath at 65°C for 30 minutes. Then in the centrifuge tube, add 1ml 5mol / L KAc and mix in ice bath for 30min, add an equal volume (4ml) of chloroform: isoamyl alcohol (24:1, v / v) and mix upside down, centrifuge at 8000rpm for 10min, take Add 2 / 3 volume of pre-cooled isopropanol to the upper water phase, mix well, and place at -20°C for 2 hours. Use a sealed capillary to pick the flocculent DNA pellet in a new 1.5ml centrifuge tube, wash it twice with 70% ethanol and air dry the pellet, add an appropriate amount of TE to fully dissolve it, phenol: chloroform: isoamyl alcohol (24:23:1, v / v / v) After extraction, add 2 volumes of ethanol and store at -20°C for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com