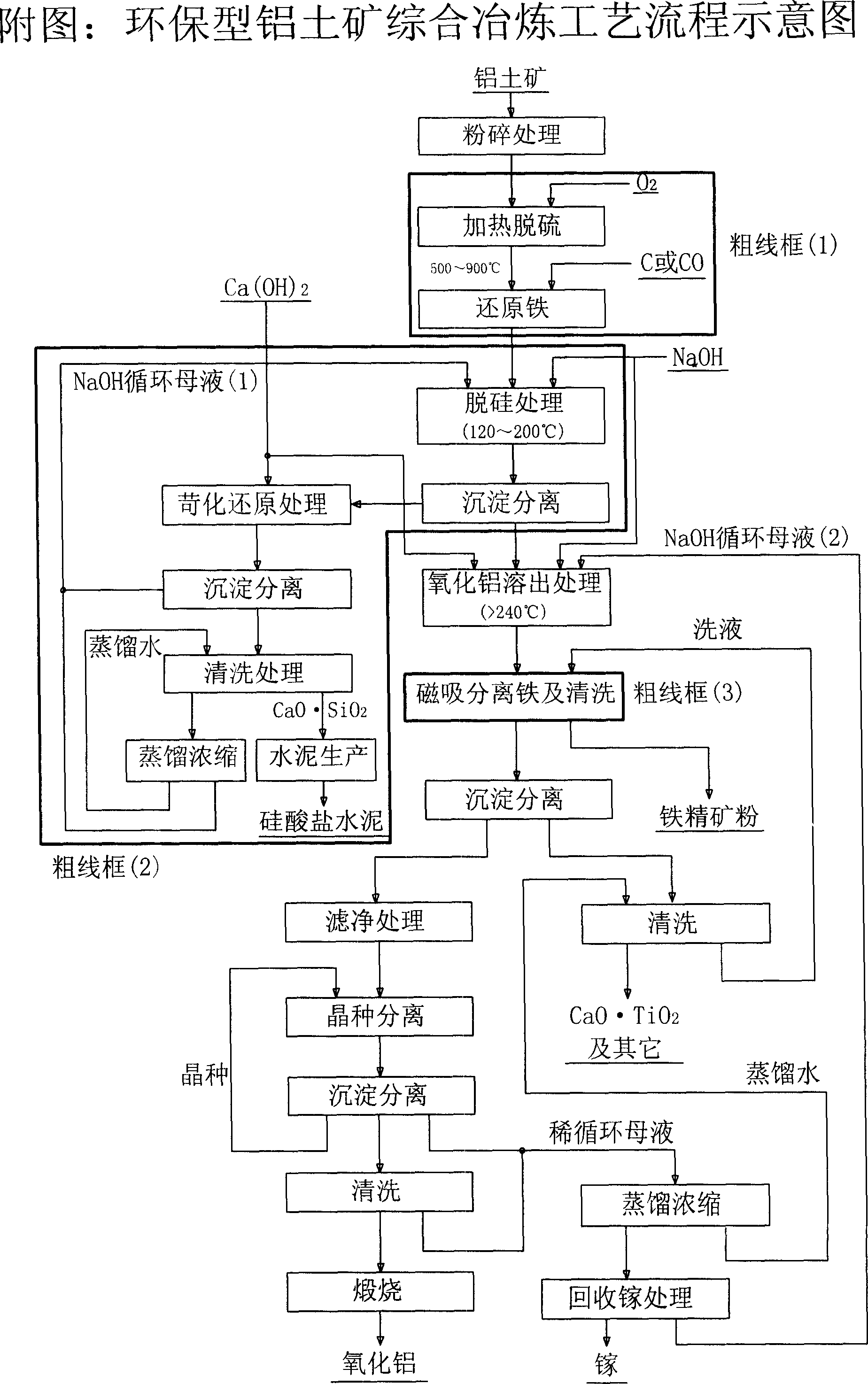

Environment-friendly type alumyte integrated smelting technology

A technical solution, an environmentally friendly technology, applied in chemical instruments and methods, solid separation, magnetic separation, etc., can solve the problems of reduced extraction rate, inability to remove quartz stone, increased smelting cost, etc., and achieve improved resource utilization and high efficiency. The effect of comprehensive development and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solution of the present invention has its specificity, complexity and advantages compared with the various disclosed Bayer dissolution technical solutions at present. If the existing equipment technology is still used to implement the technology of the present invention, not only the equipment investment is huge, but also the energy consumption will increase greatly. Therefore, it is not worth the candle. However, if the high-temperature bauxite powder after high-temperature desulfurization and iron reduction is considered to be used as the heat source material for Bayer dissolution of bauxite powder in the implementation of the technical solution of the present invention, and the desiliconization, Bayer dissolution and concentration treatment of circulating mother liquor, etc. The link adopts the "reciprocal nesting, spiral linear passage and pipeline energy conversion production technology" invented by myself to implement the scheme of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com