Automated test control system and method for wavelength tunable laser

A technology for tuning lasers and automated testing, applied in the field of lasers, can solve problems such as time-consuming and labor-intensive operations, unsuitable for large-scale and large-scale fine scanning, and single system functions that are not flexible enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

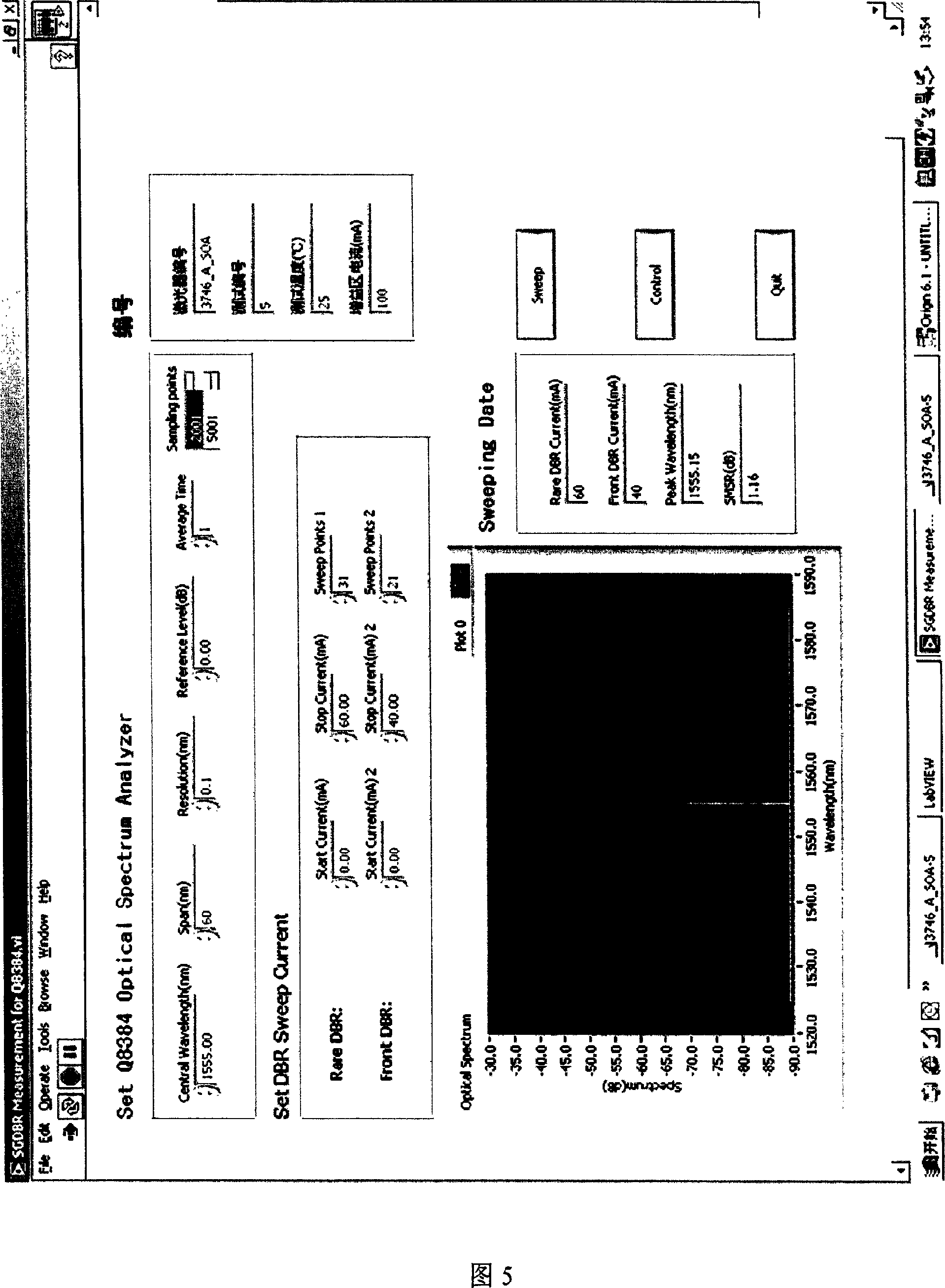

[0035] Fig. 4 is a schematic diagram of the hardware connection mode of the automatic test control system of the present invention. In the situation shown in the figure, install the GPIB board on the computer motherboard, and install the GPIB driver in the computer system. Share 3 GPIB buses for communication, connect one end of the 3 GPIB buses to the interface of the GPIB board (the GPIB interface can be superimposed and expanded), and connect the other ends to the spectrum analyzer Advantest Q8384 (or Anristsu MS9001) and 2 program-controlled current sources on the GPIB interface of IXlightwave LDX3200, and set the GPIB address to 8 on the spectrum analyzer, set the GPIB address to 1 on the program-controlled current source of the grating after driving, and set the GPIB address on the program-controlled current source of the grating before driving The address is 2. The four-segment DBR laser (SG DBR) with front and rear sampling gratings is sintered on the copper heat sink...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com