Laser based on semiconductor optical amplification chip

An optical amplification and semiconductor technology, applied in the field of semiconductor optical amplification chip lasers, to achieve the effect of realizing laser wavelength and enhancing mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

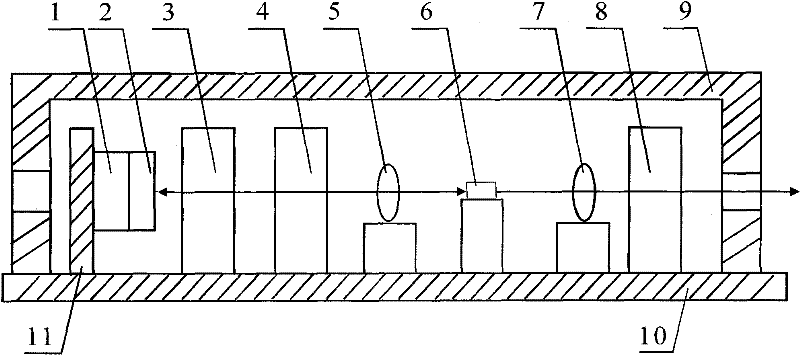

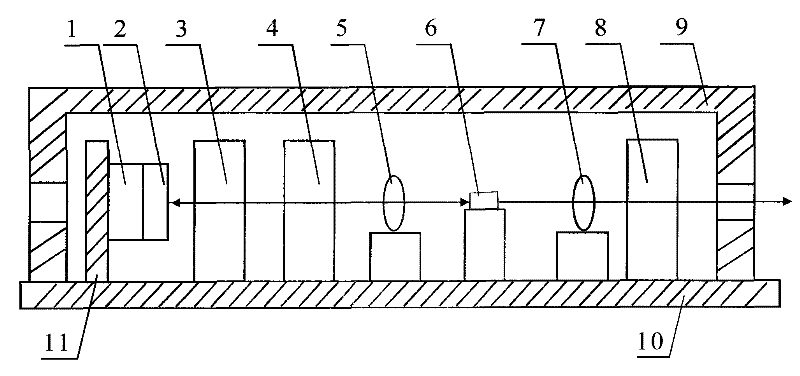

[0016] exist figure 1 Among them, the laser device based on the semiconductor optical amplification chip of the present embodiment consists of a piezoelectric transducer 1, a total reflection mirror 2, a focusing lens 3, a mode selection device 4, a first collimating lens 5, a semiconductor optical amplification chip 6, a second A collimator lens 7, a cylindrical lens 8, a cover body 9, a base plate 10, and a support block 11 are connected to form.

[0017] The base plate 10 is fixedly connected with a cover body 9 with a threaded fastening connector, and a wire hole is processed on the left side wall of the cover body 9, and the wire can pass through the wire hole, and a light exit hole is processed on the right side wall of the cover body 9 , the laser can be emitted through the light hole. The left side of the inner bottom plate 10 of the cover body 9 is fixedly connected with a support block 11 with a threaded fastener, and a piezoelectric transducer 1 is fixedly connect...

Embodiment 2

[0019] The anti-reflection film on the incident surface of the semiconductor optical amplifier chip 6 of the present embodiment is vacuum alternately vaporized 8 layers of silicon dioxide and zirconium dioxide, and the partial reflection film on the outgoing surface of the semiconductor optical amplifier chip 6 is vacuum alternately deposited 14 layers of fluoride. Magnesium and Calcium Fluoride. 24 layers of aluminum oxide and tantalum pentoxide reflection films are alternately vacuum-evaporated on the mirror surface of the total reflection mirror 2 . The mode selection device 4 is a Fabry-Perot etalon with a bandwidth of less than 200 GHz and a transmittance of 80%. The other components of this embodiment and the coupling relationship of the components are the same as those of Embodiment 1.

Embodiment 3

[0021] The anti-reflection film on the incident surface of the semiconductor optical amplifier chip 6 of this embodiment is vacuum alternately vaporized 12 layers of silicon dioxide and zirconium dioxide, and the partial reflection film on the outgoing surface of the semiconductor optical amplifier chip 6 is vacuum alternately deposited 18 layers of fluoride Magnesium and Calcium Fluoride. 30 layers of aluminum oxide and tantalum pentoxide reflective films are vacuum-evaporated alternately on the mirror surface of the total reflection mirror 2 . The mode selection device 4 is a Fabry-Perot etalon with a bandwidth of less than 200 GHz and a transmittance of 80%. The other components of this embodiment and the coupling relationship of the components are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com