Radiant ray-sensitive lithographic printing plate precursor

a lithographic plate and precursor technology, applied in thermography, instruments, photosensitive materials, etc., can solve the problems of complex exposure and development, insufficient methods, complex apparatus,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0039] A series of (i) a material capable of light / heat conversion and low melting point dispersed particles (e.g., wax particles) containing reaction component B which reacts with reaction component A, and (ii) a dispersion medium containing reaction component A. When the light energy given by radiant ray irradiation dissolves low melting point dispersed particles by light / heat conversion, reaction component A starts to contact with reaction component B in a molten liquid phase, a self-exothermic reaction continues without irradiation of radiant rays thereafter, and the separation of an image part from a non-image part progresses. The light / heat conversion material and reaction component B may be the same (e.g., a metal powder) or different series comprising other materials.

[0040] The following materials or material series can be exemplified as the analogous examples.

[0041] a. A series of (i) solid acid having a low melting point (e.g., a higher fatty acid) containing a light / heat ...

examples i-1 to i-8

[0186] Lithographic printing plate precursors comprising an iron powder as a material (a) having a light / heat conversion function and a self-exothermic reaction function, and a polymer compound generating a sulfonic acid by heating as a material (b) having a separating function of an image part from a non-image part were prepared.

[0187] Iron Fine Powder

[0188] The above-described alloy of iron fine powder having Fe / Co / Al / Y ratio of 100 / 20 / 5 / 5, a particle size having a long axis length of 0.1 .mu.m, a short axis length of 0.02 .mu.m, and a specific surface area of 60 m.sup.2 / g was kneaded in a continuous kneader with the polymer (polymer compound) shown below and dispersed using a sand mill.

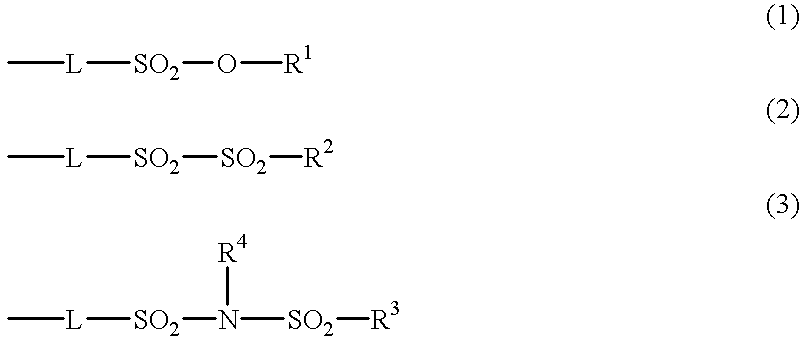

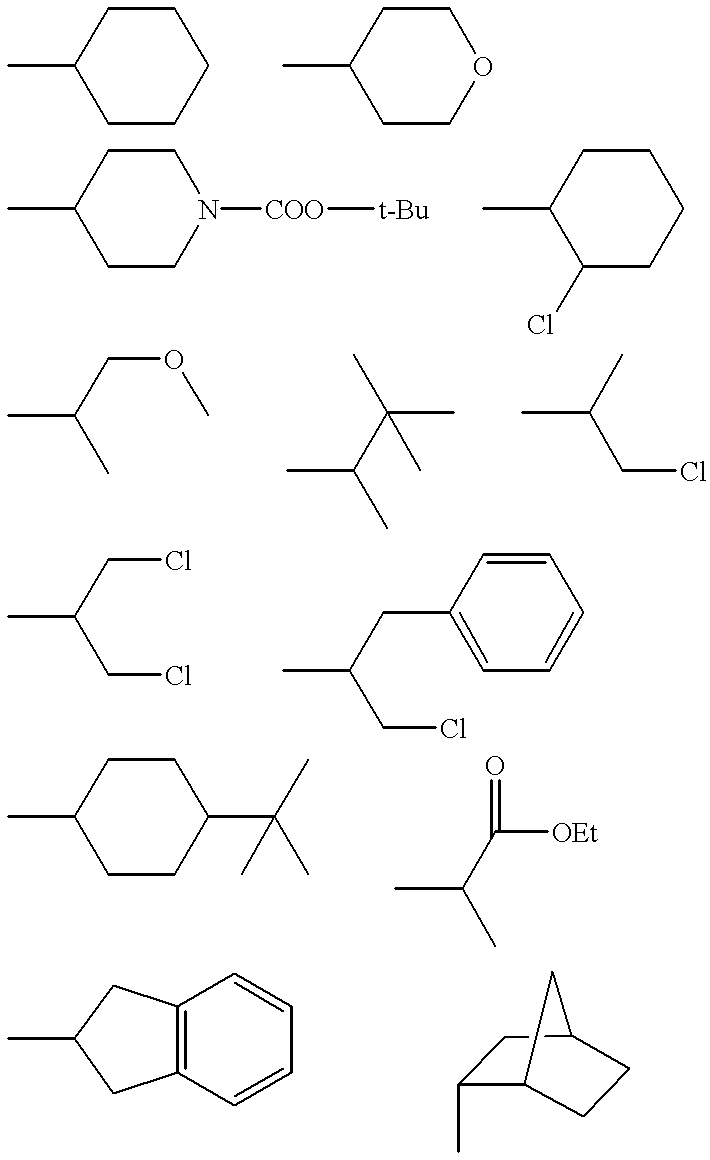

[0189] Synthesis of Sulfonic Acid-Generating Type Polymer Compound

[0190] (1) Synthesis of Monomer (1)

[0191] Two hundred (200) ml of acetonitrile, 11 g of hexyl alcohol and 8.8 g of pyridine were put in a three neck flask having a capacity of 500 ml and stirred. Twenty point two (20.2) grams of viny...

example ii-1

[0200] The following compositions were put in a paint shaker (manufactured by Toyo Seiki Co., Ltd.) together with glass beads and dispersed for 60 minutes, and then glass beads were filtered, thereby a dispersion was obtained.

4 Iron fine particle powder 50 g Titanium oxide sol (30% solution) STS-01 167 g (manufactured by Ishihara Sangyo Kaisha Ltd.) Tetramethoxysilane (manufactured by 50 g Shin-Etsu Chemical Co., Ltd.) Concentrated hydrochloric acid 0.5 g (manufactured by Wako Pure Chemical Industries Ltd.) Ethanol 783 g Water 117 g

[0201] The above-prepared coating solution was coated on a PET support having a thickness of 188 .mu.m using a wire bar coater in coating weight of 1 g / m.sup.2, and then dried at 100.degree. C. for 10 minutes, thereby a lithographic printing plate precursor was obtained.

[0202] Iron Fine Particle Powder

[0203] Fe / Co / Al / Y ratio: 100 / 20 / 5 / 5

[0204] Particle size:

[0205] Long axis length: 0.1 .mu.m

[0206] Short axis length: 0.02 .mu.m

[0207] Specific surface area: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydrophobicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com