Deposition apparatus and deposition method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0104] [Embodiment 1]

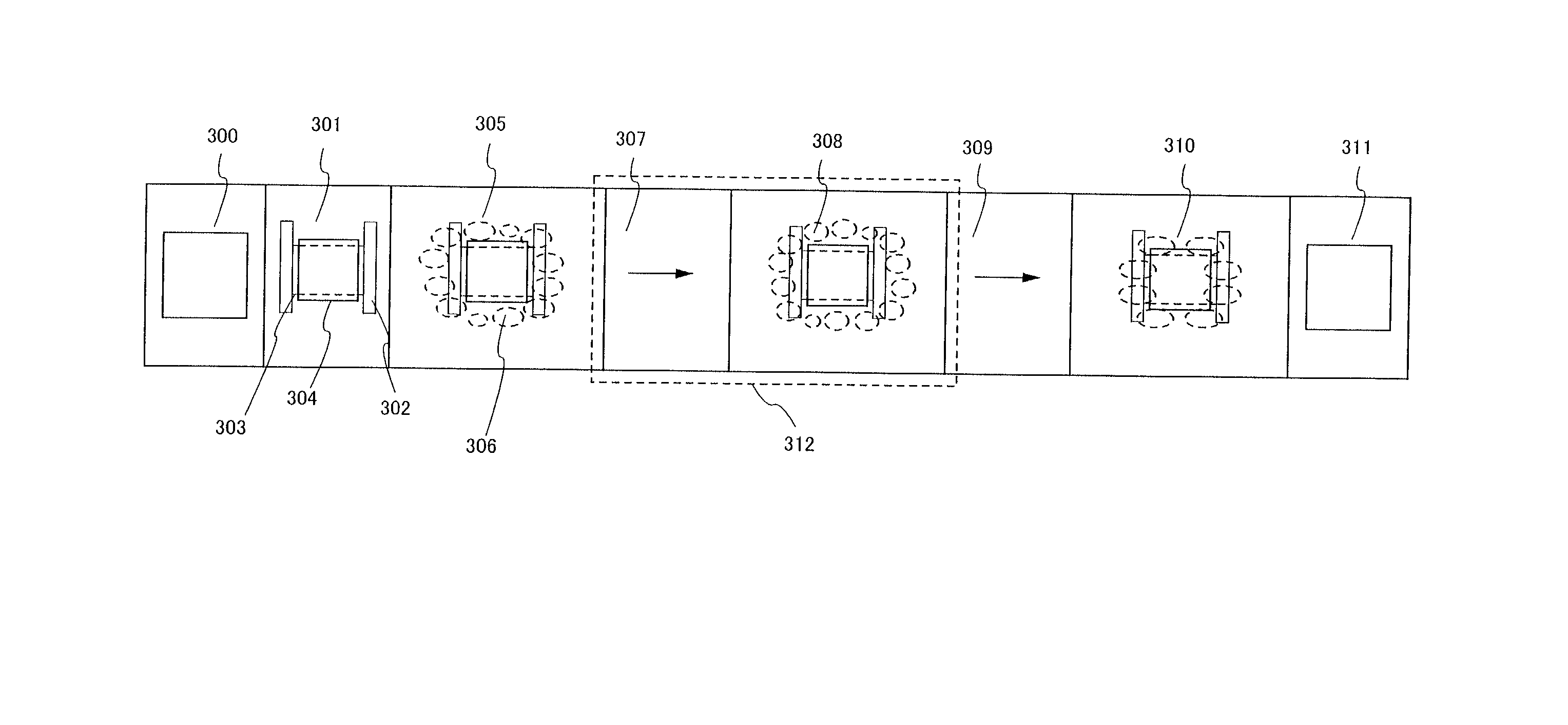

[0105] An explanation will be given of the case where the deposition apparatus of the present invention is the inline scheme, with reference to FIG. 5. In FIG. 5. reference numeral 501 denotes a load chamber, from which a substrate is transported. Note that the term substrate as used in this embodiment is to be understood to mean the one with either an anode or cathode (anode used in this embodiment) for use as one electrode of a luminescent element being formed thereon. In addition the load chamber 501 comes with a gas exhaust system 500a, wherein this exhaust system 500a is constituted including a first valve 51, a turbo molecular pump 52, a second valve 53, a third valve 54 and a dry pump 55.

[0106] Additionally in this embodiment, as the material used for inside of respective processing chambers such as a gate-blocked load chamber, an alignment chamber, a deposition chamber, a sealing chamber and an unloading chamber, a material such as aluminum or stainless ...

embodiment 2

[0147] [Embodiment 2]

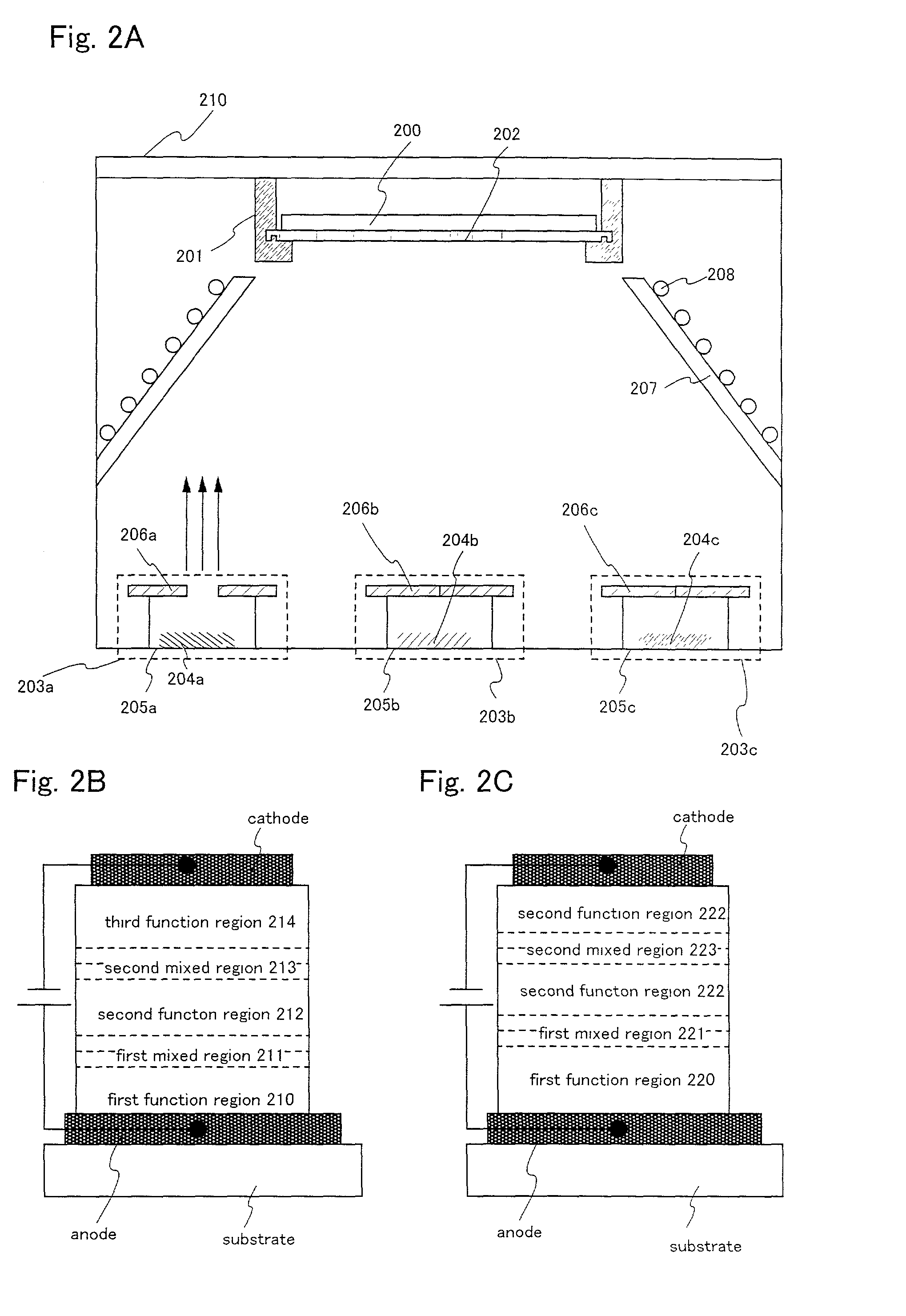

[0148] A deposition apparatus of the present invention will be explained with reference to FIGS. 7A and 7B. In FIGS. 7A and 7B, reference numeral 701 denotes a transfer chamber, wherein this transfer chamber 701 comprises a transfer mechanism A702 for performing transport of a substrate 703. The transfer chamber 701 is set in a pressure-reduced atmosphere and is coupled by a gate with each processing chamber. A substrate is transported to each processing chamber by the transfer mechanism A702 upon opening of the gate. Additionally while exhaust pump such as a dry pump, a mechanical booster pump, a turbo molecular pump (magnetic floatation type) or cryopump is employable for pressure reduction of the transfer chamber 701, the turbo molecular pump of the magnetic flotation type is preferable in order to obtain high-degree vacuum states with higher purity.

[0149] An explanation will be given of each processing chamber below. Note that the transfer chamber 701 is set...

embodiment 3

[0196] [Embodiment 3]

[0197] In this embodiment, a deposition apparatus will be explained with reference to FIGS. 8A and 8B, which is different in substrate transfer method and structure from the deposition apparatus of the inline type as has been indicated in the embodiment 1.

[0198] In FIGS. 8A and 8B, a substrate 804 as loaded into a load chamber 800 is transported toward a first alignment unit 801 which is coupled thereto via a gate (not shown). Note that the substrate 804 is subjected to alignment by the method discussed in FIGS. 4A through 4E and then fixed to a holder 802 along with a metal mask 803.

[0199] And, the substrate 804 is transferred to a first deposition unit 805 together with the holder 802. Note here that the first alignment unit 801 and the first deposition unit 805 are coupled together via no gates and have the same space. Then, in this embodiment, a rail 812 is provided as a means for enabling free movement between the first alignment unit 801 and the first depo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Color | aaaaa | aaaaa |

| Luminescence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com