Feathery copper fiber body, process for production thereof, and copper microcoil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

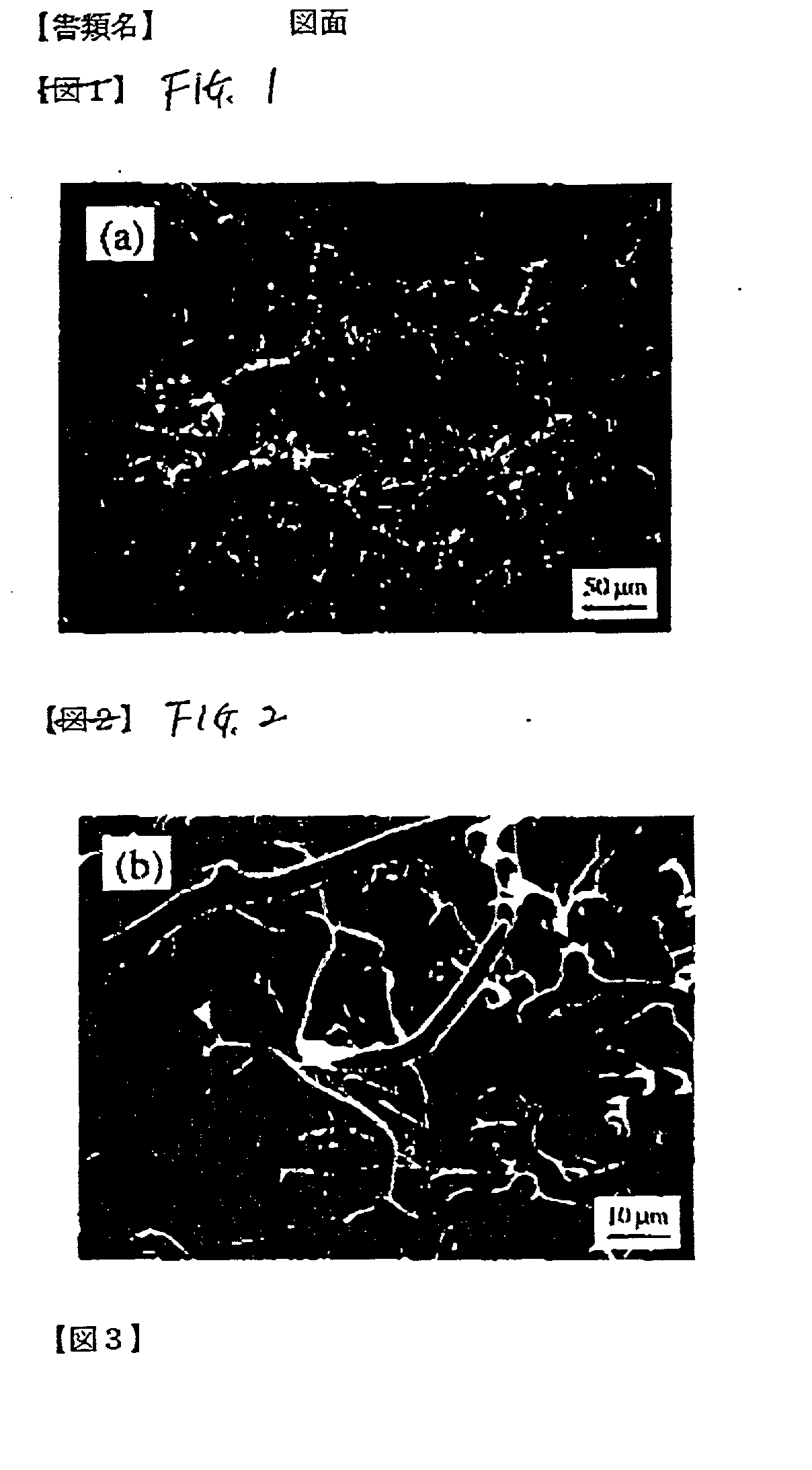

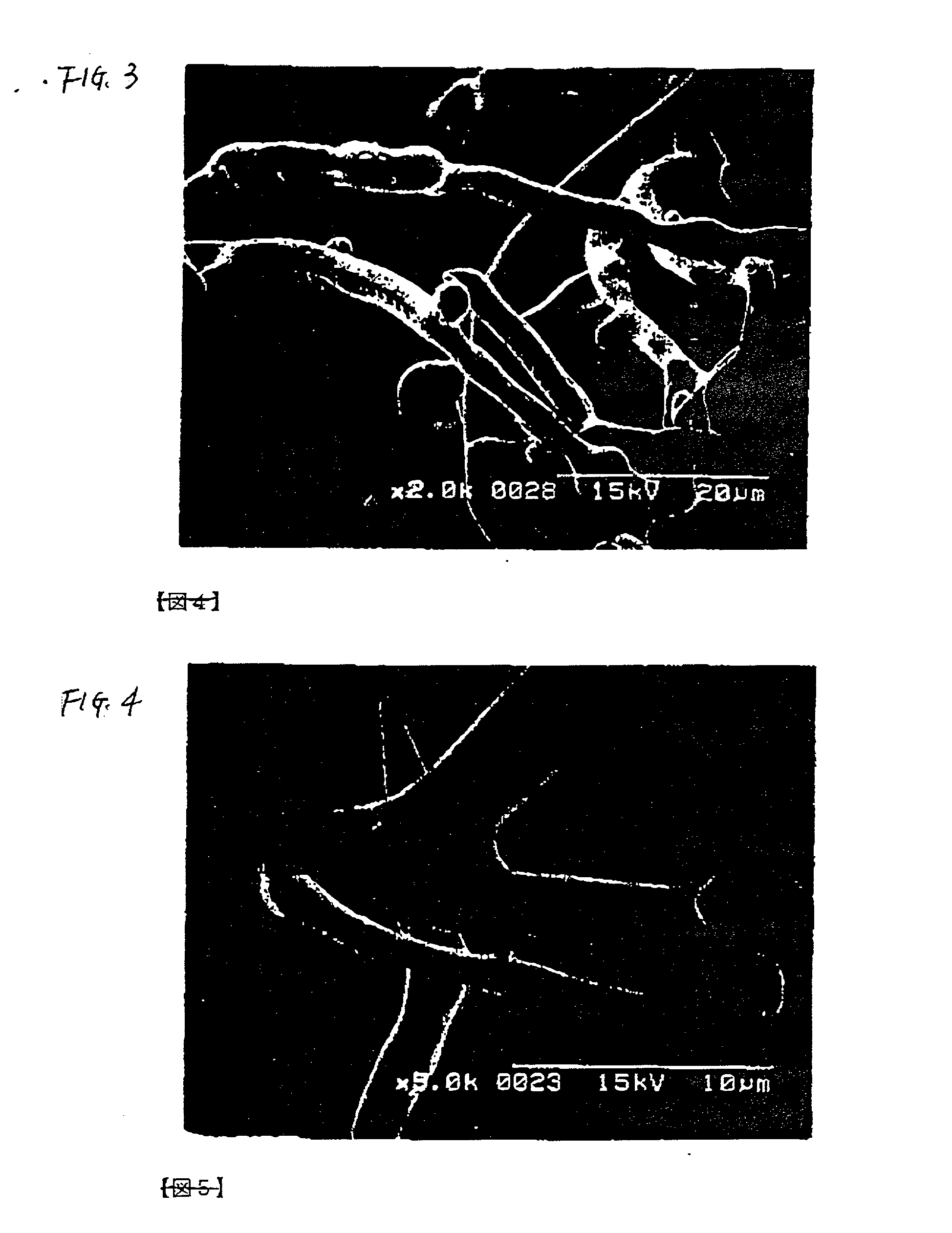

[0035] The process for the production of the copper fiber body of the present invention will be further described hereinafter.

[0036] As carbon black there was used Denka Black FX-35 (hereinafter referred to as "CB") produced by DENKI KAGAKU KOGYO K.K. In various experiments, various components, including copper chloride, copper iodide, carbon black, tin chloride and nickel chloride, were mixed in a proportion (by weight) set forth in Tables 1 to 4 below. The mixture was put in a porcelain boat, and then introduced into a tubular electric furnace in which the atmosphere within had been kept as set forth in Tables 1 to 4 and heated to a predetermined temperature as set forth in Tables 1 to 4 where it was then treated for a period of time as set forth in Tables 1 to 4.

[0037] The figures shown in the column of copper chloride, copper iodide, carbon black, tin chloride and nickel chloride in Tables 1 to 4 each indicate mixing ratio by weight. The figures in the column of argon, methane a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by volume | aaaaa | aaaaa |

| Percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com