Resist pattern swelling material, and method for patterning using same

a technology of resist pattern and swelling material, which is applied in the field of resist pattern swelling material, can solve the problems of inability to obtain resist pattern swelling effect, inability to increase the thickness, and inability to substantially neglect the swelling effect of resist pattern by the process with chemical solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0134] (First Embodiment)

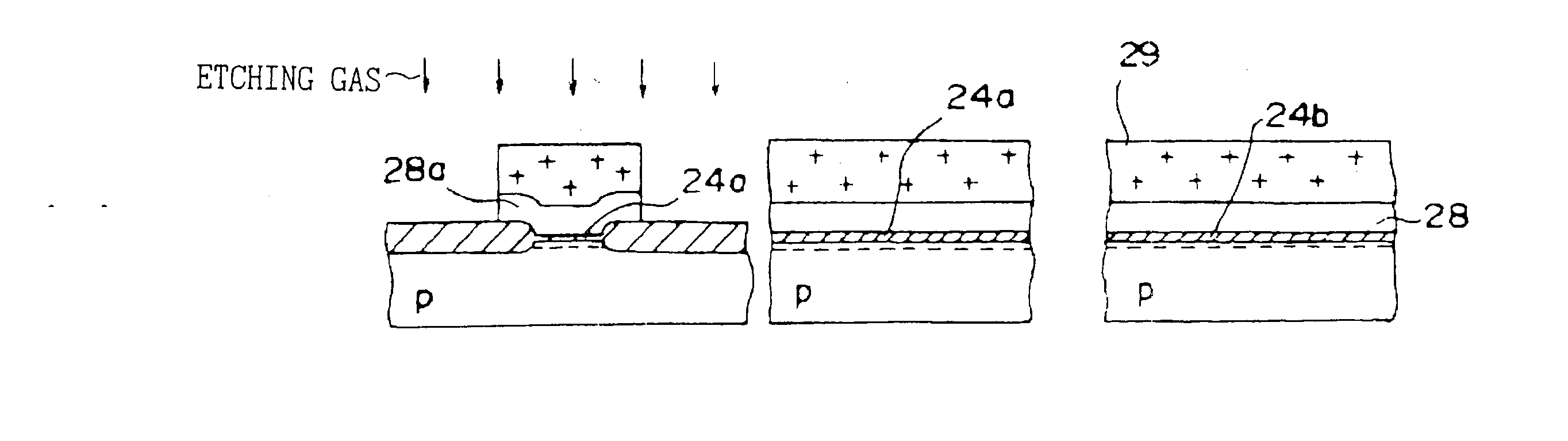

[0135] Refer to FIG. 4(a):

[0136] FIGS. 4(a) to 4(e) are cross-sectional views showing profiles of the resist pattern before and after the swelling process. The cross-sectional views of the essential portion including the resist pattern are sequentially shown in FIGS. 4(a) to 4(e).

[0137] After an element region is provided on a semiconductor substrate (not illustrated) with the well known method, a silicon oxide film, for example, is formed to the entire surface as an interlayer insulation film with the CVD (Chemical Vapor Deposition) method. Thereafter, a positive resist is formed on the flat surface by the uniform coating process with the well known spin coating method. For selection of an example of the positive resist material, it is preferable as explained above to select the alicyclic group based resist from the viewpoint of the resolution and resistance for dry-etching.

[0138] Refer to FIG. 4(b):

[0139] Next, the resist film 1 is patterned with the well ...

second embodiment

[0146] (Second Embodiment)

[0147] In the second embodiment, the second invention of the present invention, namely an embodiment of the swelling material to be formed by coating to cover the surface of resist pattern is constructed with a phenol resin and a solvent which includes at least a kind of cross linking agent selected from a group of the cross linking agents consisting of melamine derivative, urea derivative and uryl derivative and does not easily dissolve the resist material as the lower layer on which a pattern is already formed. This second embodiment is intended, by forming a film on the resist pattern surface with a material obtained through addition of the particular cross linking agent and a resin material known as the resist material to the particular resin composition, to assure excellent affinity with the resist pattern surface with a little dissolution of the pattern surface by reaction of the existing resist material in the film with the relevant resist pattern su...

third embodiment

[0150] (Third Embodiment)

[0151] Next, as the third embodiment, the third invention of the present invention, namely an embodiment of the resist pattern swelling method or the like will be explained, in which after formation of a resist pattern, the surface of the relevant resist pattern is coated first with an aqueous solution including a non-ionic interfacial active agent, for example, a polyoxyethylene-polyoxypropylene condensation product based interfacial active agent or other agents, thereafter coated with a resin composition selected from polyvinyl alcohol or the like and with a water-soluble composition including a cross linking agent consisting of melamine derivative, urea derivative and uryl derivative. In this example, affinity of the resist pattern surface is previously improved with the aqueous solution including the interfacial active agent and thereafter affinity of the resist pattern surface is improved before coating and formation of the pattern swelling material by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com