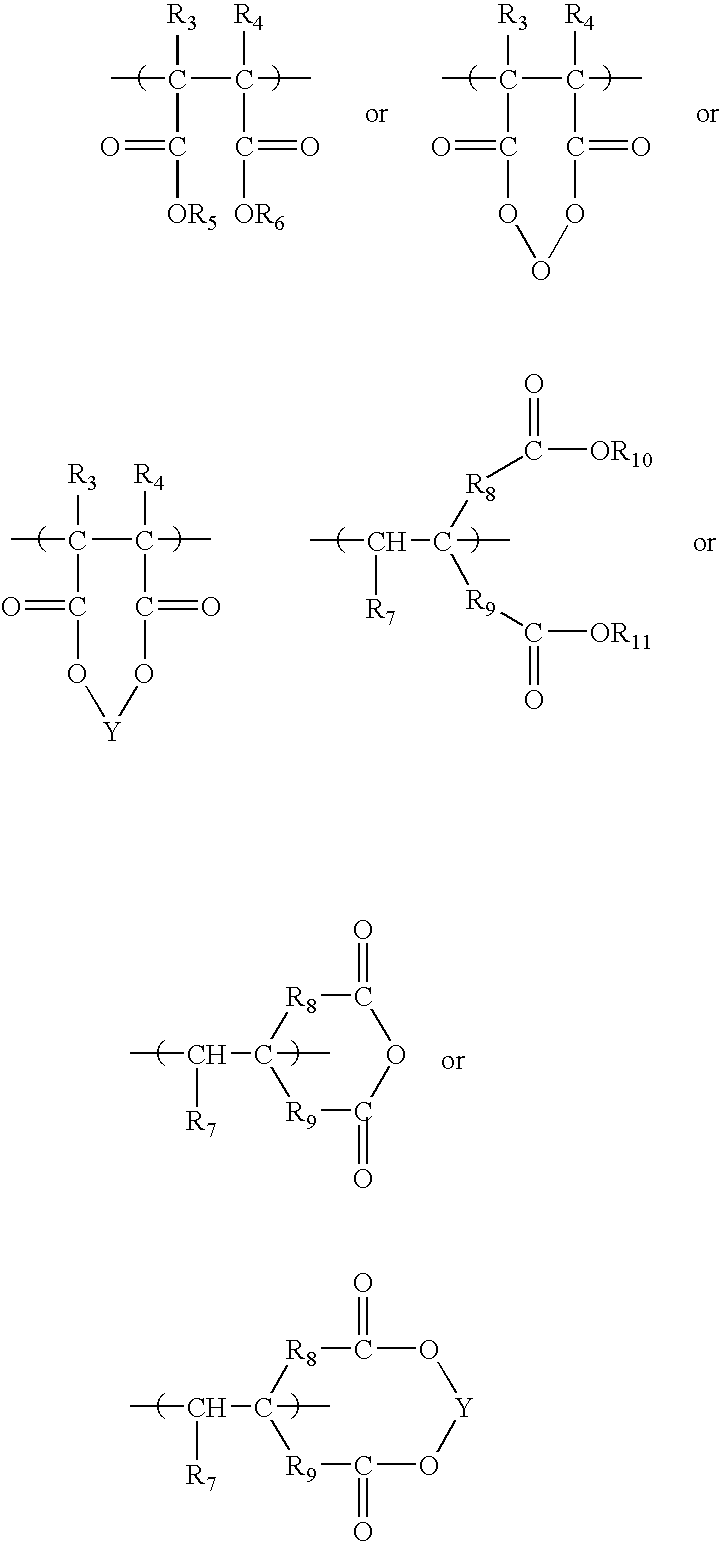

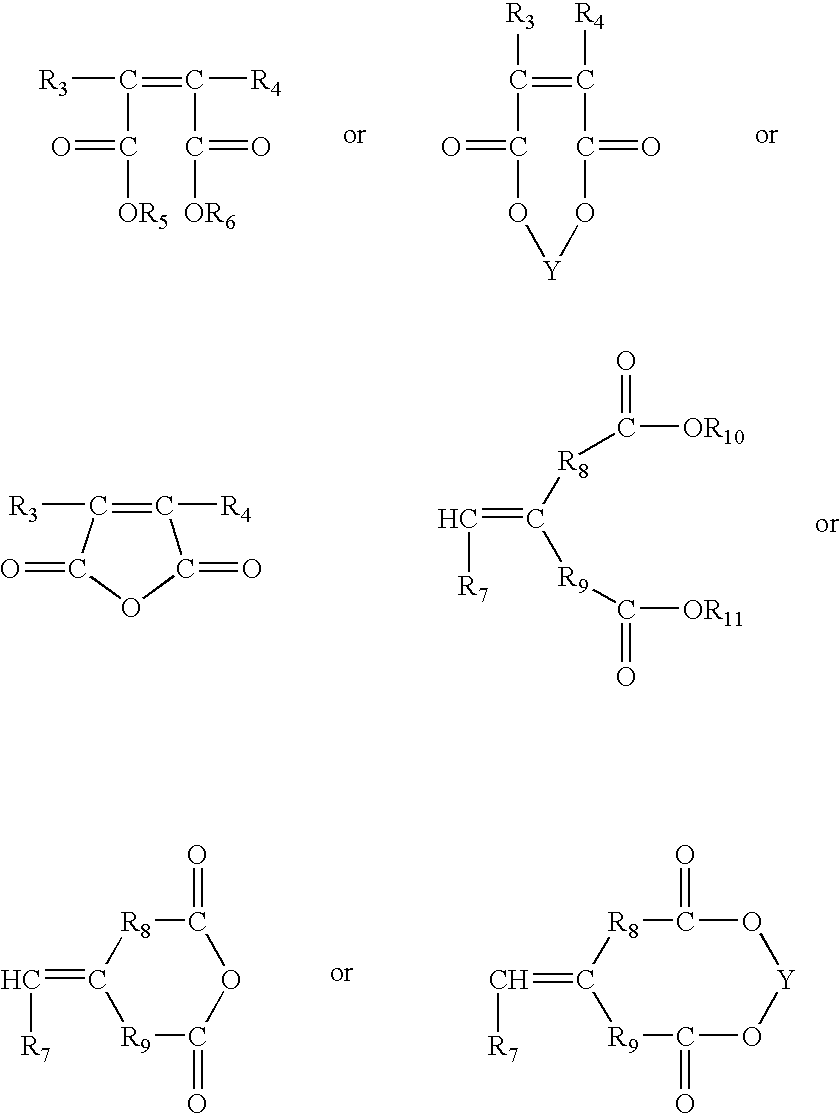

Anionic polymers composed of dicarboxylic acids and uses thereof

a technology of dicarboxylic acid and anionic polymer, which is applied in the field of anionic polymers composed of dicarboxylic acids, can solve the problems of significant limitation in use, affecting the application, and reducing the utility of the polymer,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

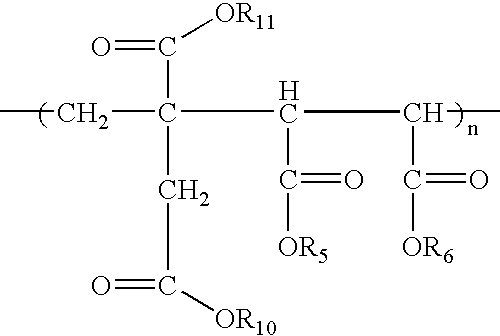

[0041] This reaction was carried out in equipment similar to that used in Example 1 above. The following procedure was followed: 847 g purified water was placed into the reactor. Next, 172 g itaconic acid and 130 g maleic anhydride were added with vigorous stirring. This mixture was heated to about 85-90.degree. C., at which temperature this mixture exists as a clear solution. When the mixture reached the desired temperature, 15 g of potassium persulfate was added to the solution. The reaction mixture was allowed to stir for 3 hours, and a second portion of persulfate, equal to the first, was added, and allowed to react for a further 3 hours. Product was isolated in the same manner as described for Example 1. A schematic representation of this reaction is shown below 5

example 3

[0042] The procedure of Example 2 was followed, but the product was not isolated. Instead, it was diluted with water to give a 10% w / w solution. Then, 6.62 g ZnO was added to 200 g of this solution. The oxide dissolved in the liquid with stirring. This solution was then dried to a white highly water-soluble powder.

example 4

[0043] The procedure of Example 2 was followed, but the product was not isolated. Instead, it was diluted with water to give a 30% w / w solution. 6.66 g CuO was then added to 260 g of this solution. The oxide dissolved in the liquid with stirring and heating to about 60 degrees C. This solution was then dried to a green-colored highly water-soluble powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com