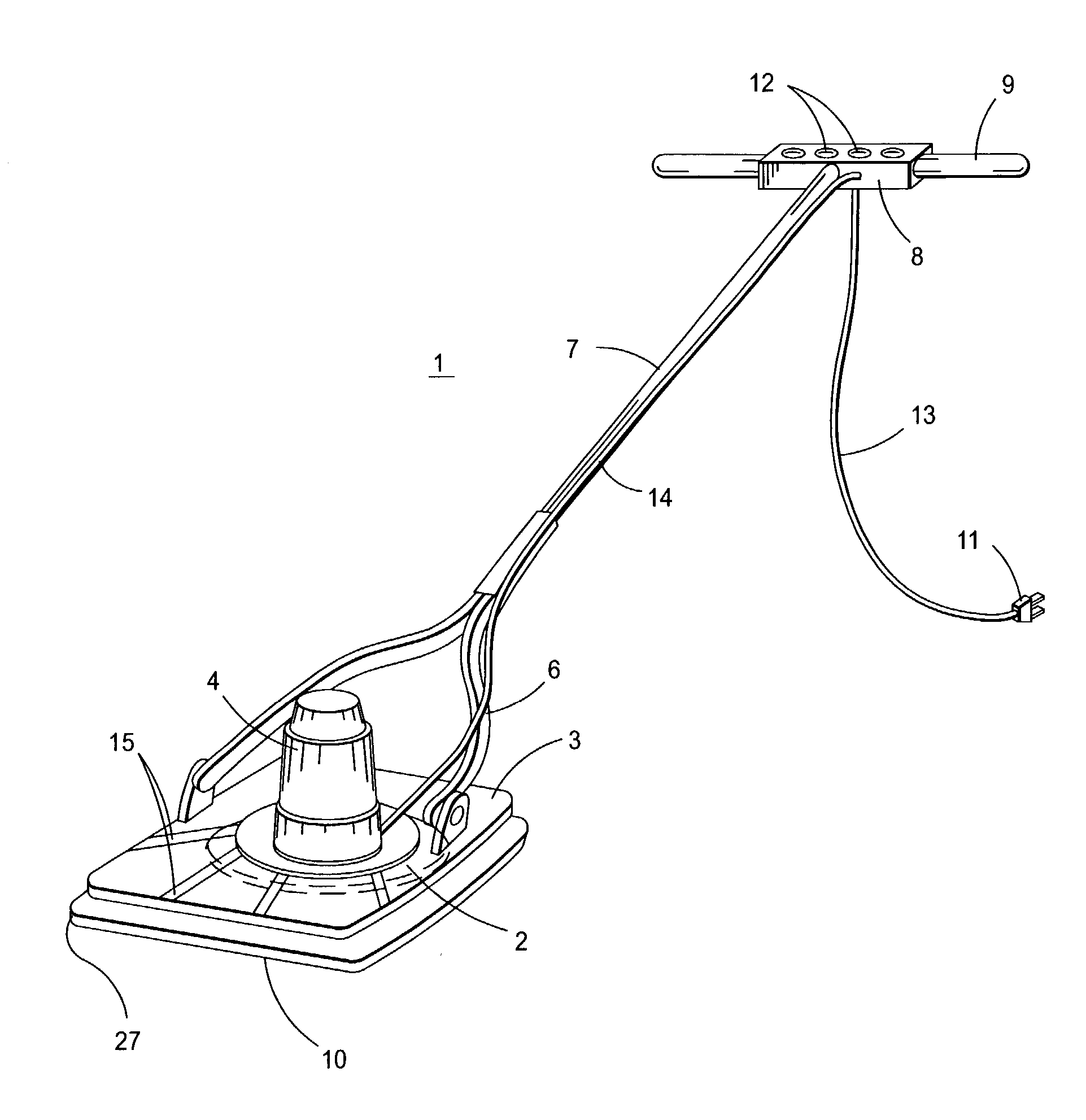

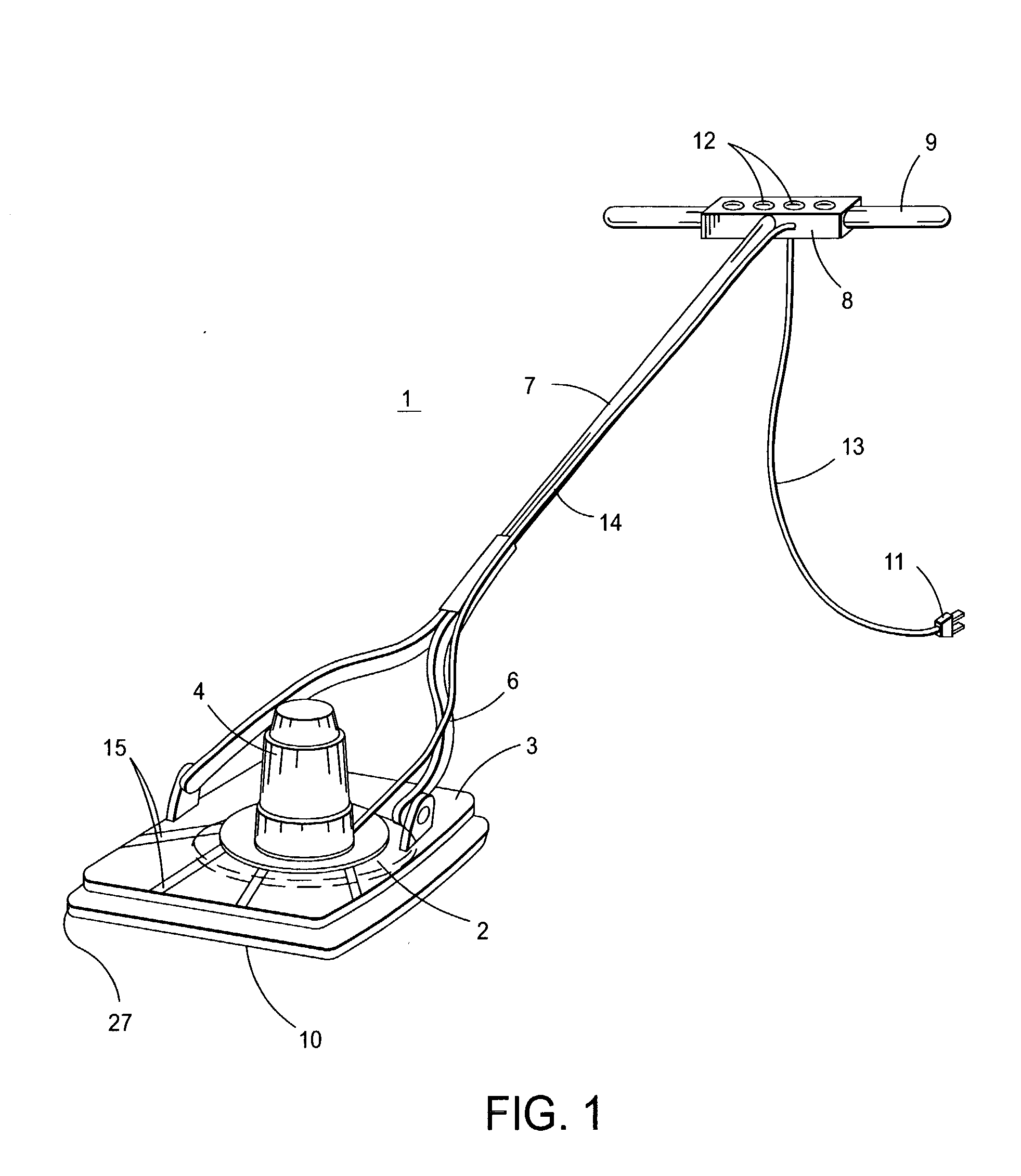

[0018] The present invention overcomes the problems and disadvantages of the prior art by utilizing vibration or agitation simultaneously with heat and a

cleaning agent. The

cleaning agent is applied either directly to the workpiece or to a cloth which may reside under a base plate attached to a mechanical vibrator or

agitator, which plate then moves the cloth in a very tight

circular motion, or back and forth against the workpiece, or up and down against the workpiece, or in combinations of such movements, in small increments. The increments of movement may be increased in size by appropriate adjustment of the

agitator, to increase the travel of the base plate and cloth, thereby increasing the cleaning effect when the present invention is used on carpets having thicker

pile, or other workpieces having special characteristics. Heat is simultaneously applied to the workpiece by the mechanical

agitator by means of a

heating element or elements attached to or imbedded within the base plate of the mechanical agitator. The cloth so worked against the workpiece may be changed from time to time as

particulates and other matter are dissolved, and picked up by the cleaning agent and cloth, and held by the agent on or in the cloth.

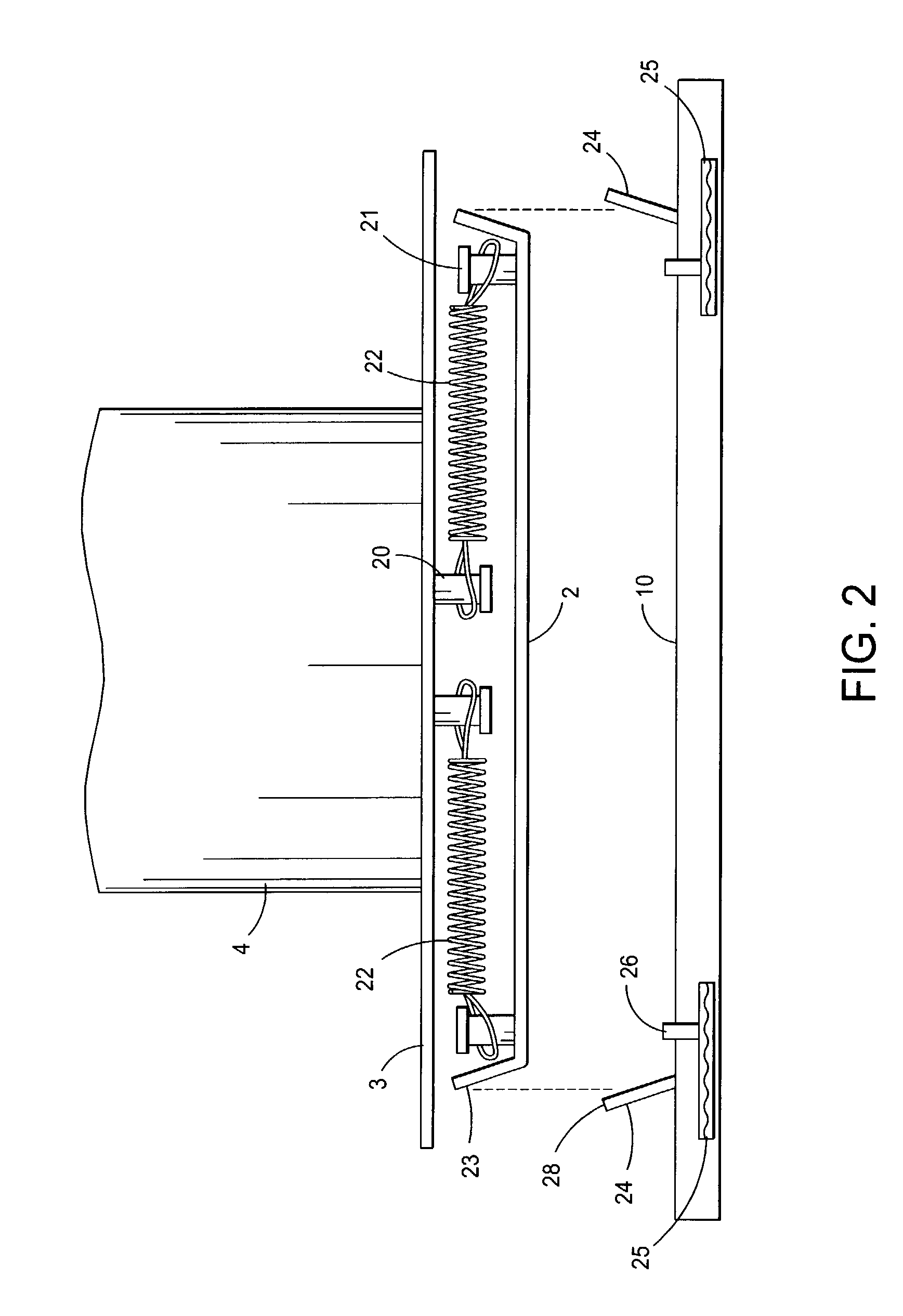

[0026] The greatest flexibility is placement of heating elements is presently accomplished by attaching modular

heating element pads to various locations on the bottom side of the base plate. Such heating pads may be formed of thin-wire or thin-layer resistance elements, including nickle wire or foil, encased in

silicon and fiberglass, or plasticized

fiber, material, which resistance elements are capable of generating any

operating temperature desirable for the cleaning process of the present invention up to the

melting point of the workpiece. At such temperatures, the

silicon and fiberglass material is capable of

continuous operation without melting, hardening, or otherwise breaking down. The benefit of all such materials used as heating elements in the present invention is application of heat directly to the upper side of a towel or other cleaning element properly positioned in the cleaning

machine, i.e. as close as possible to the workpiece to be cleaned. By such positioning, heat may be applied during the cleaning process as closely as possible to the workpiece to be cleaned, to maximize the benefit of heat within the process of the present invention.

[0028] The heating elements may be placed anywhere on the base plate, including the upper sides of any edge of the place, the entire lower surface of the base plate, or at only selected areas on the lower surface of the base plate. However, the preferred placement for the present invention when used as a rug cleaner is by placement of a

heating element or elements covering substantially the entire lower side of the base plate. From such position, and with appropriately connected switches for controlling current to each heating element individually, a operator may direct heat evenly throughout the entire base plate (while heat may be directed as desired to various portions of the base plate utilizing separate heading elements).

[0030] A cleaning solution is used with the cleaning

machine (floor-treating

machine, hand-held machine, or otherwise). The combination of such solution with the heat generated, directed, and applied by such apparatus maximizes the cleaning action of the present invention. The solution may be as simple as

plain water, which may be used as a

solvent for water-soluable substances, and a vehicle for removal of such substances. However, it is more usual to use water and detergent, or a combination of compounds containing water and either

soap or detergent, which

soap or combination of compounds combine chemically with non-

water soluble soils or

dirt. As with

soap and detergents used in other applications, the combination of cleaning compound with fat-based soils proceeds hydrophobically with the fat soluble substances, so that the water in the combination of compounds may pick up the soap or detergent hydrophilically, and so float the fat soluble substance away (to lodge on the terrycloth or other towel residing under the base plate of the cleaning apparatus when in operation). In most such cleaning applications, additional rinsing is necessary to remove the soap or detergent residue from the workpiece to an acceptable level. In other cases, a solution containing one or more hydrocarbons may be used to dissolve soils adhering to the workpiece which are

hydrocarbon based. Thus,

motor oil may be dissolved using a cleaning fluid containing carbon compounds, including, for exceptionally tough cleaning jobs, generally available compounds containing combinations of N-

Butyl Acetate, Isoparaffinic Hydrocarbons, and

Propylene Glycol Methyl

Ether Acetate. The benefit of using such

hydrocarbon solvents is that further rinsing to remove the cleaning fluid after removal of the soil is generally not necessary.

[0035] By the above process, a user or operator may clean a large area or a small area, utilizing the benefits of each element of the invention. More specifically, the operator may take

advantage of (1) the increased

chemical activity attendant upon elevated temperature, as chemical processes proceed about twice as fast with each ten

degree Celsius increase in temperature, (2) the increased cleaning effect resulting from use of a cleaning agent, such as detergent, or detergent and

solvent combination, (3) the increased efficiency of cleaning as the cleaning agent either chemically combines with or dissolves the soil adhering to a workpiece at a

raised temperature, and (3) the increased cleaning effect resulting from direct application of power oscillating "scrubbing" motion, as the towel which is affixed to the base plate of the present invention is vigorously rubbed against the workpiece to increase direct contact between these pieces.

Login to View More

Login to View More  Login to View More

Login to View More