Graphite granules and their method of fabrication

a graphite granule and graphite technology, applied in the field of graphite granules, can solve the problems of deterioration of cycle and high current characteristics, increasing demand for power sources of portable electronic products, and increasing complexity of electronic products, etc., to achieve excellent high current characteristics, excellent electrochemical properties, and high reversible specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

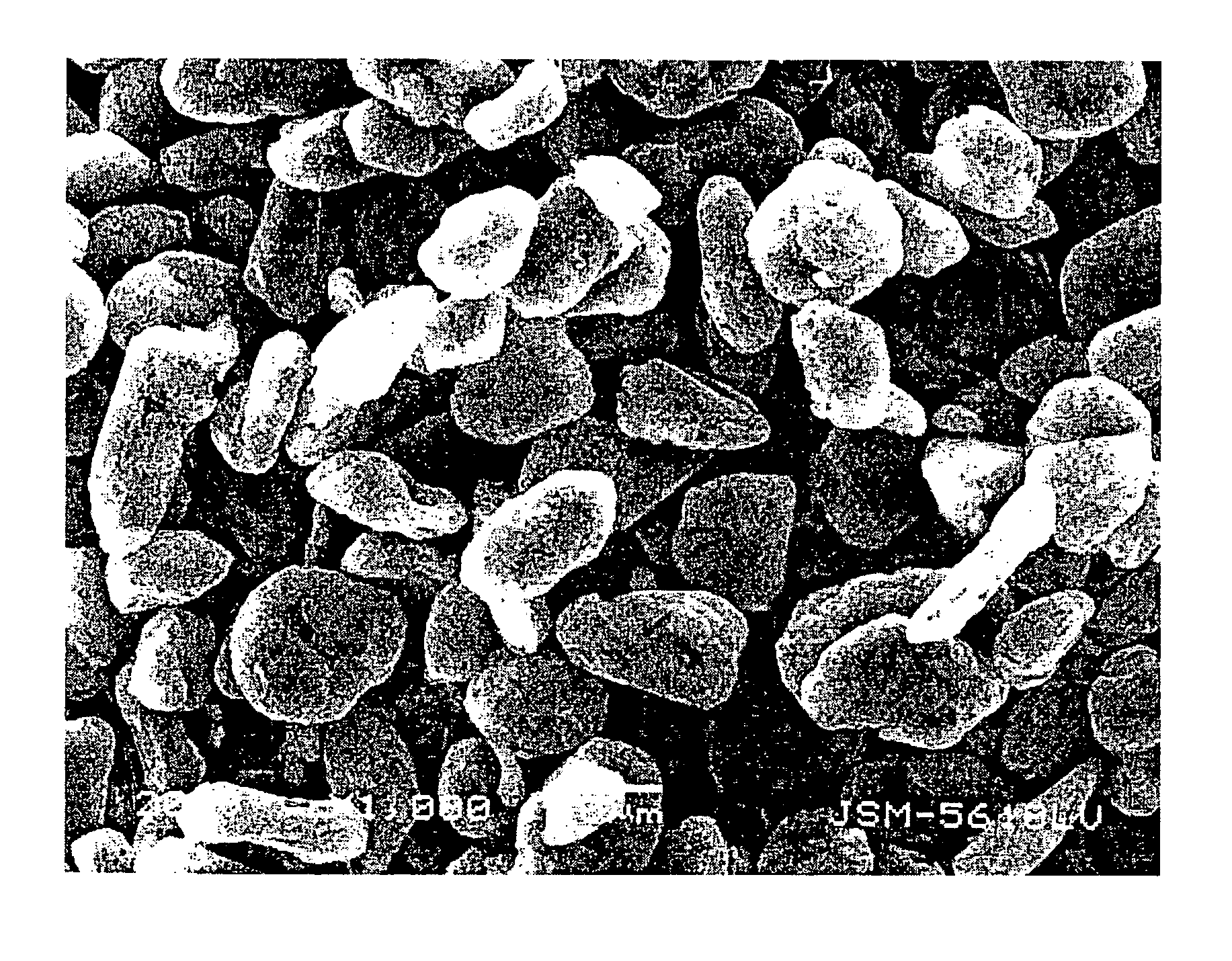

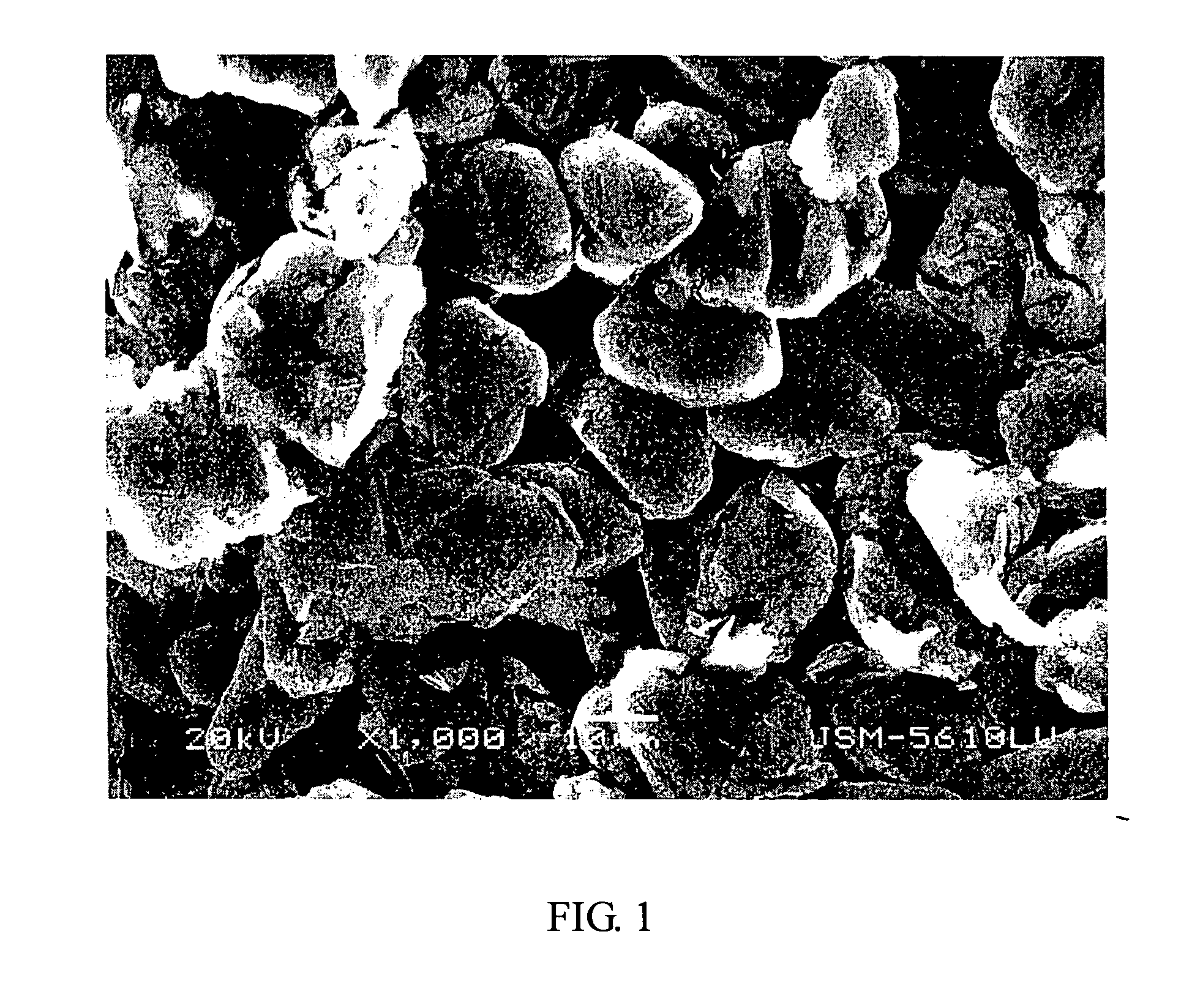

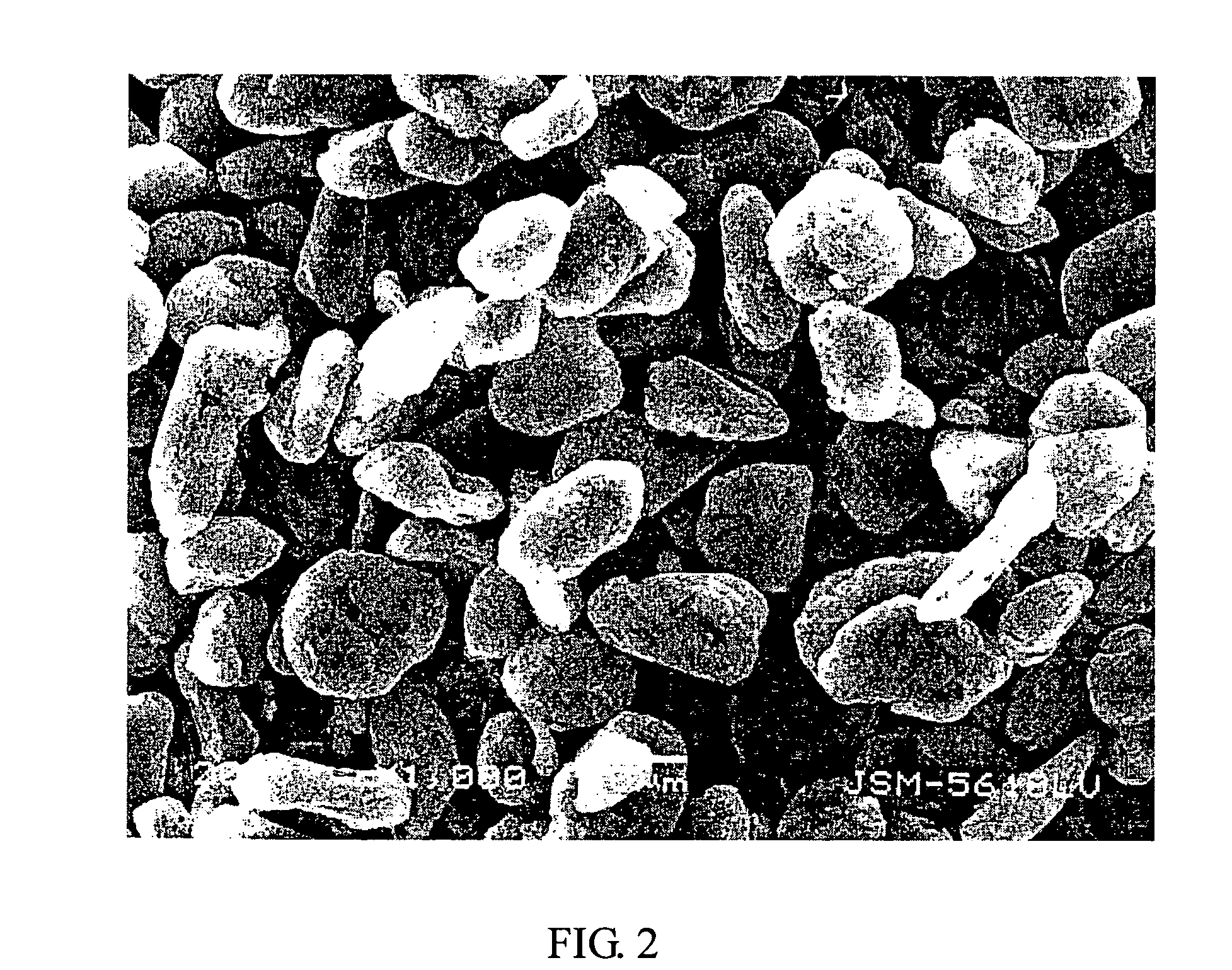

Image

Examples

embodiment 1

[0042] The following steps comprise the method for the fabrication of Embodiment 1:

[0043] Dissolve 8 g of petroleum coke in carbon tetrachloride to formulate 200 ml of 4% surface modifying solution;

[0044] Immerse 100 g of unimproved dried natural graphite granules and immerse in the surface modifying agent organic solution;

[0045] Stir at 300 rpm speed for 1 hour to form a thin layer of surface modifying membrane on the surface of the unimproved graphite granules;

[0046] Filter the coated graphite granules that are obtained; Heat to dry and sift with 300 mesh;

[0047] Put sifted coated graphite granules into sealed tubular high temperature furnace. Pass highly pure nitrogen at 10 liters / min of flow volume and increase the temperature at 15.degree. C. / min to 400.degree. C. and hold the temperature for 1 hour; and

[0048] Increase the temperature at 10.degree. C. / min to 1000.degree. C. and hold the temperature for 3 hours. Lower the temperature naturally to room temperature to obtain the im...

embodiment 2

[0050] In this embodiment, the surface modifying solution is a 5% coal pitch in tetrahydrofuran. Other than this, all other steps and specifications are the same as Embodiment 1. The improved graphite granule obtained from this embodiment has fundamentally the same average granule diameter D.sub.50 and crystallite interlayer spacing, d.sub.002. as the improved graphite granules of Embodiment 1.

embodiment 3

[0051] In this embodiment, the surface modifying solution is a 3% petroleum pitch and chloroform solution. Other than this all other steps and specifications are the same as Embodiment 1. The improved graphite granules obtained from this embodiment has fundamentally the same average granule diameter D.sub.50 and crystallite interlayer spacing, d.sub.002, as the improved graphite granules of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| granule diameter | aaaaa | aaaaa |

| granule diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com