Optical connector assembly

a technology of optical connectors and connectors, applied in the field of optical connector assemblies, can solve the problems of reducing alignment tolerance, complicated alignment procedures of these types of assemblies, and more conventional packaging, so as to facilitate coupling procedures, overcome slight misalignments of optical fibers, and maximize coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

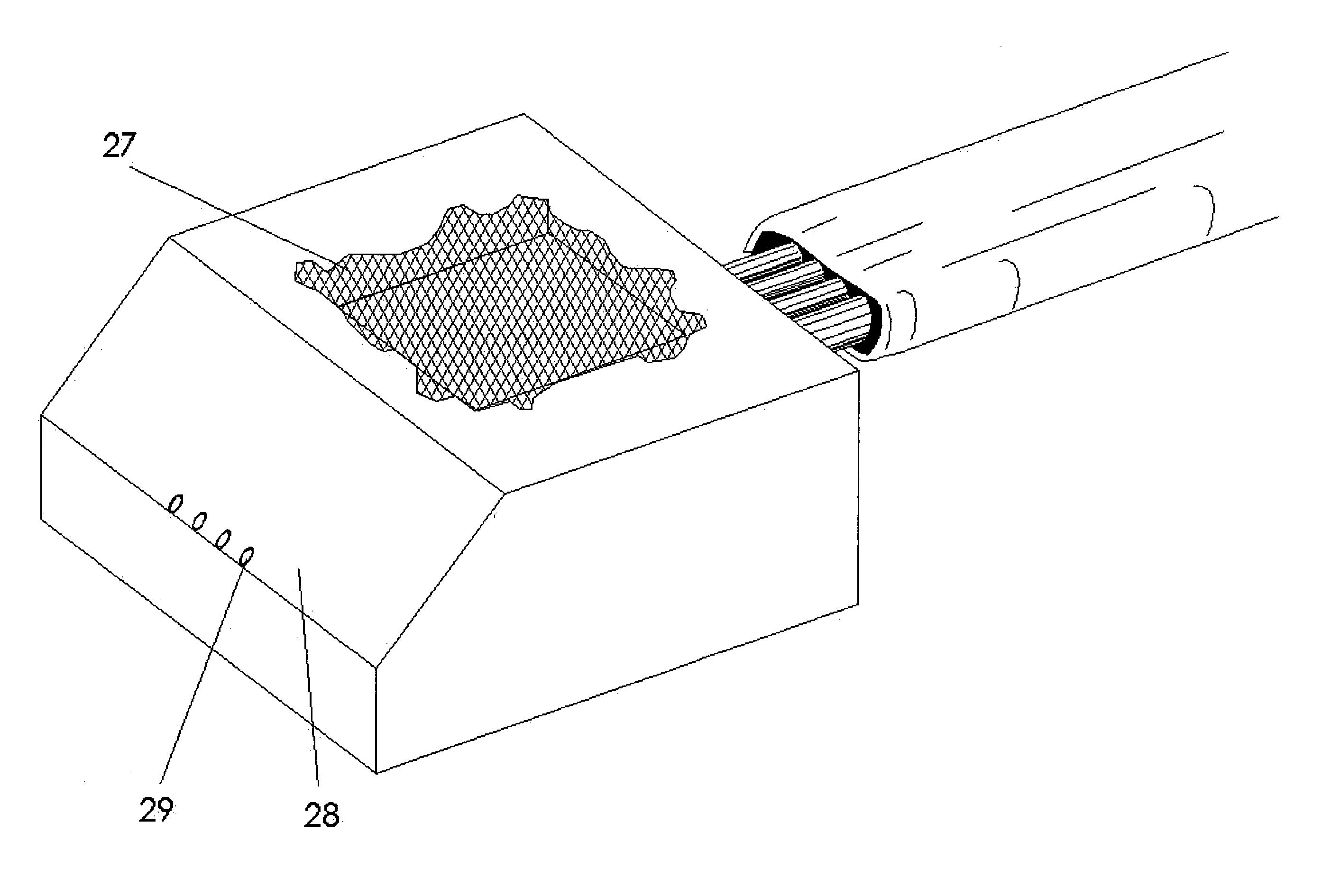

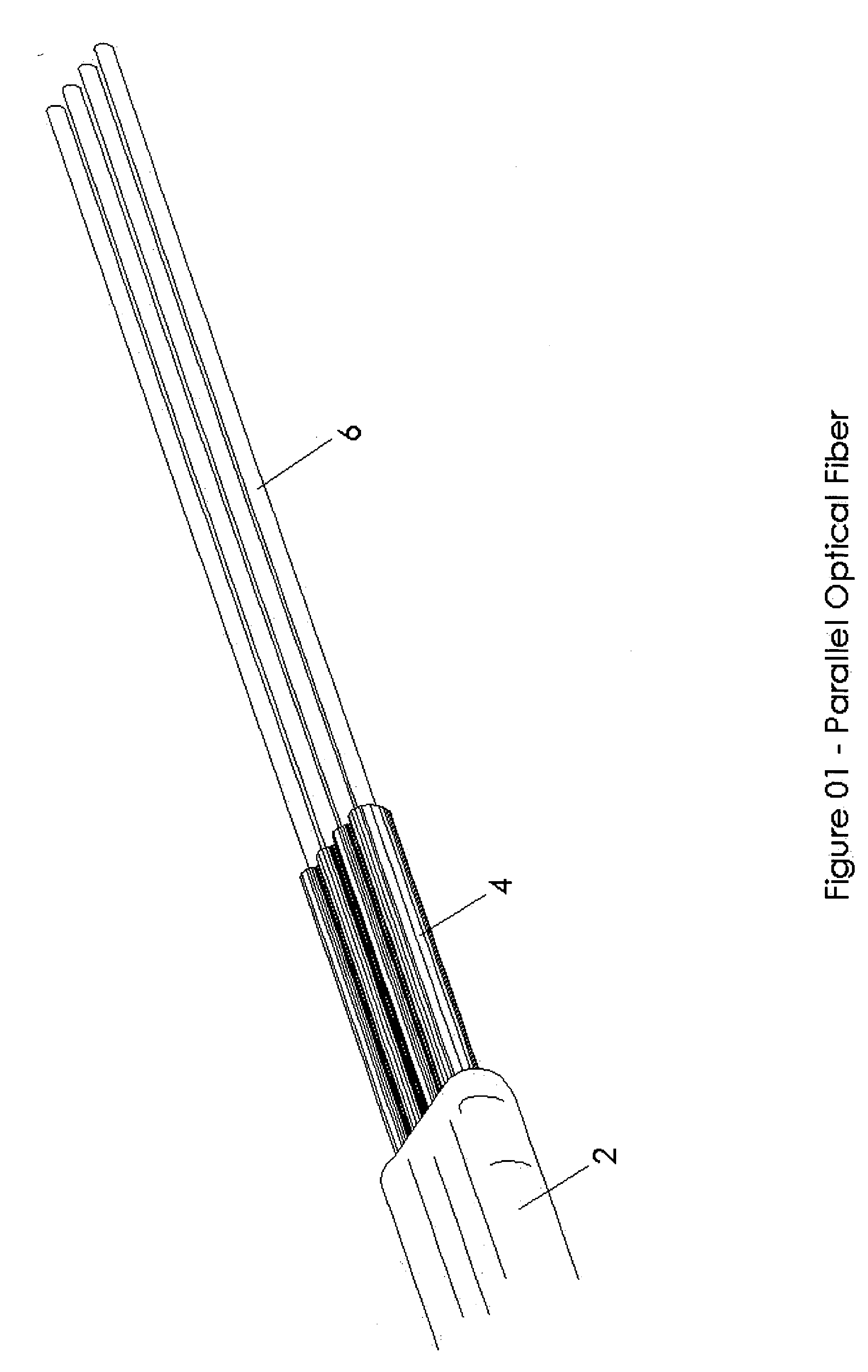

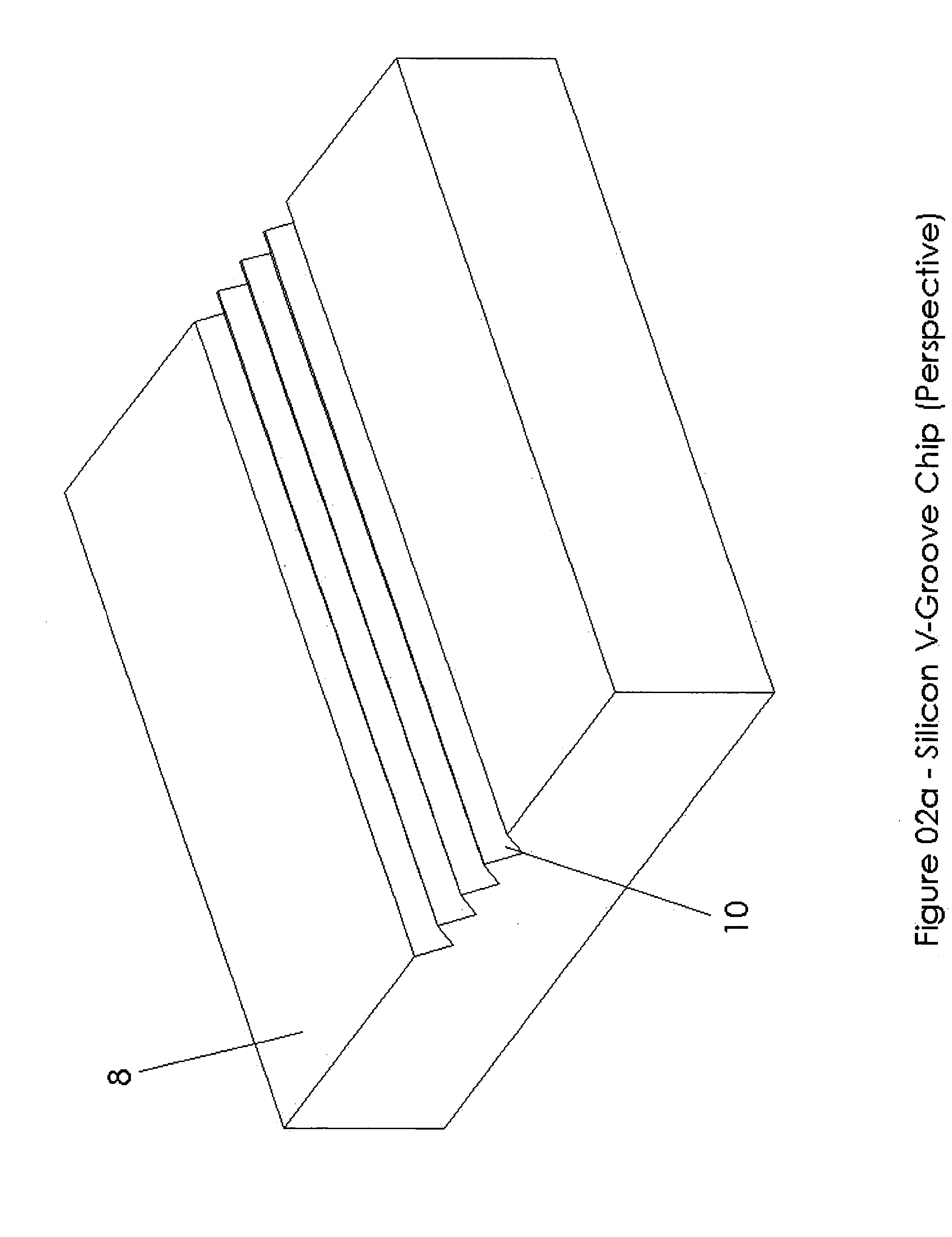

[0046] The parallel optical connector is a mechanical structure used to connect a parallel optical fiber ribbon to an array of optoelectronic devices, such as a vertical cavity surface emitting laser (VCSEL), or photodetector array.

[0047] The parallel optical connector consists of a structure to rigidly hold optical fibers in the same plane and pitched from each other at 250-microns. One end of the structure is polished at a 45-degree angle to create a reflective glass-air interface at the fiber tips. This interface can reflect light at 90-degrees by either total internal reflection (TIR) when the glass-air interface is preserved, or by depositing a reflective metal layer on the exposed tips of the fiber. The reflective metal layer may be made of gold, silver, etc.

[0048] Light directed at the 45-degree tips of the optical fiber will be reflected and coupled into the optical fiber orthogonal to the initial direction. In this situation, light will pass though the side of the optical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com