Method of reducing dislocation-induced leakage in a strained-layer field-effect transistor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

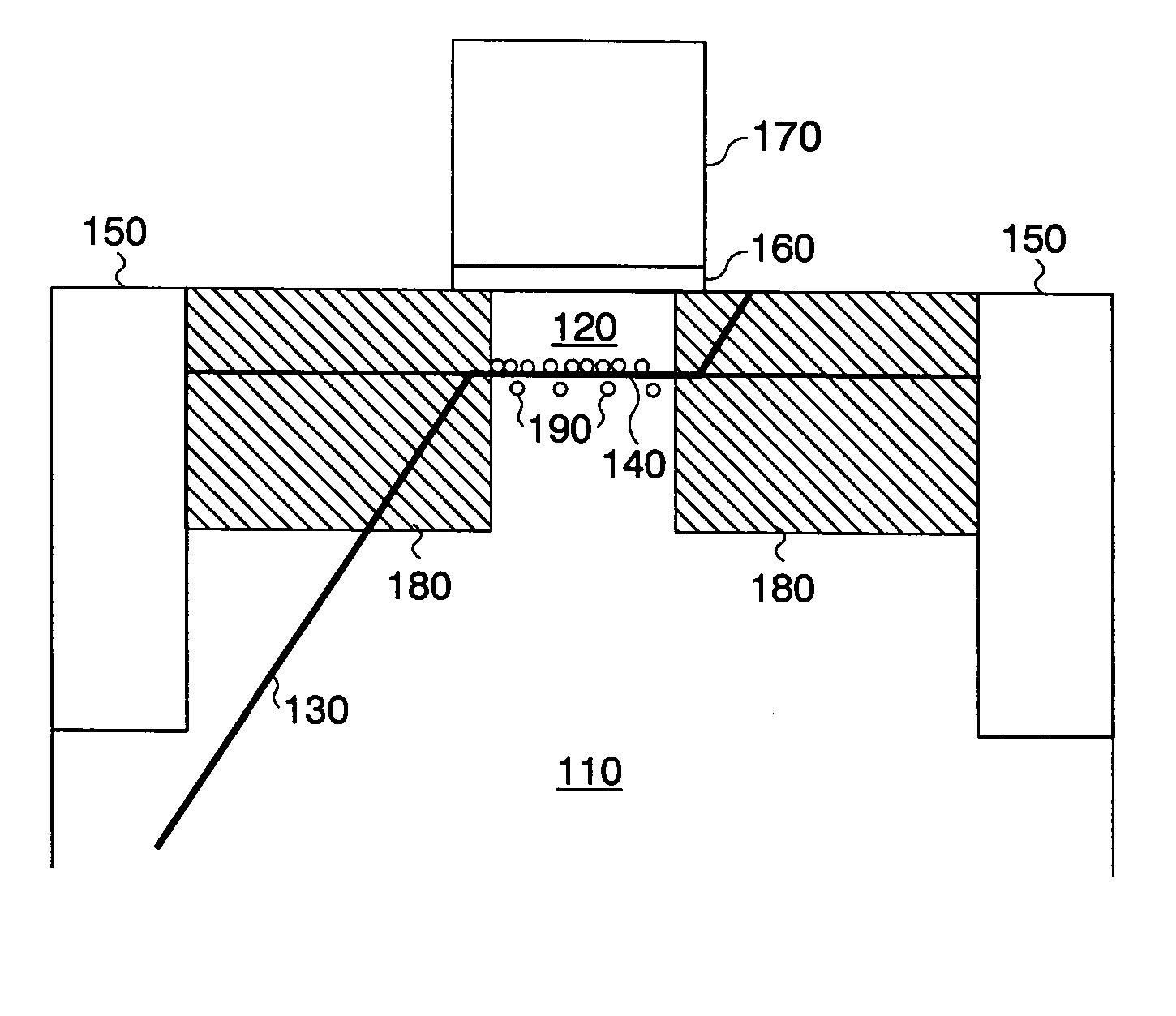

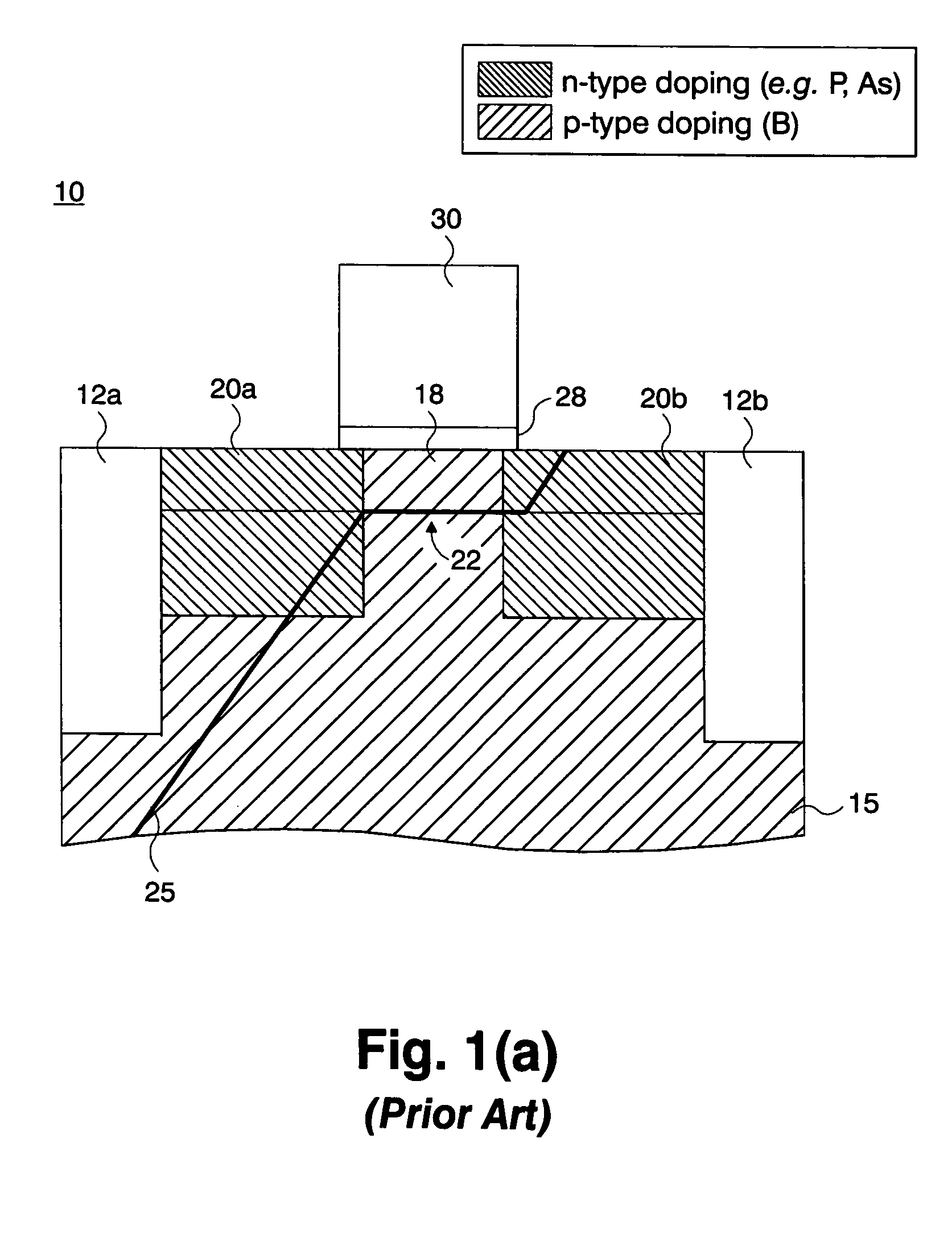

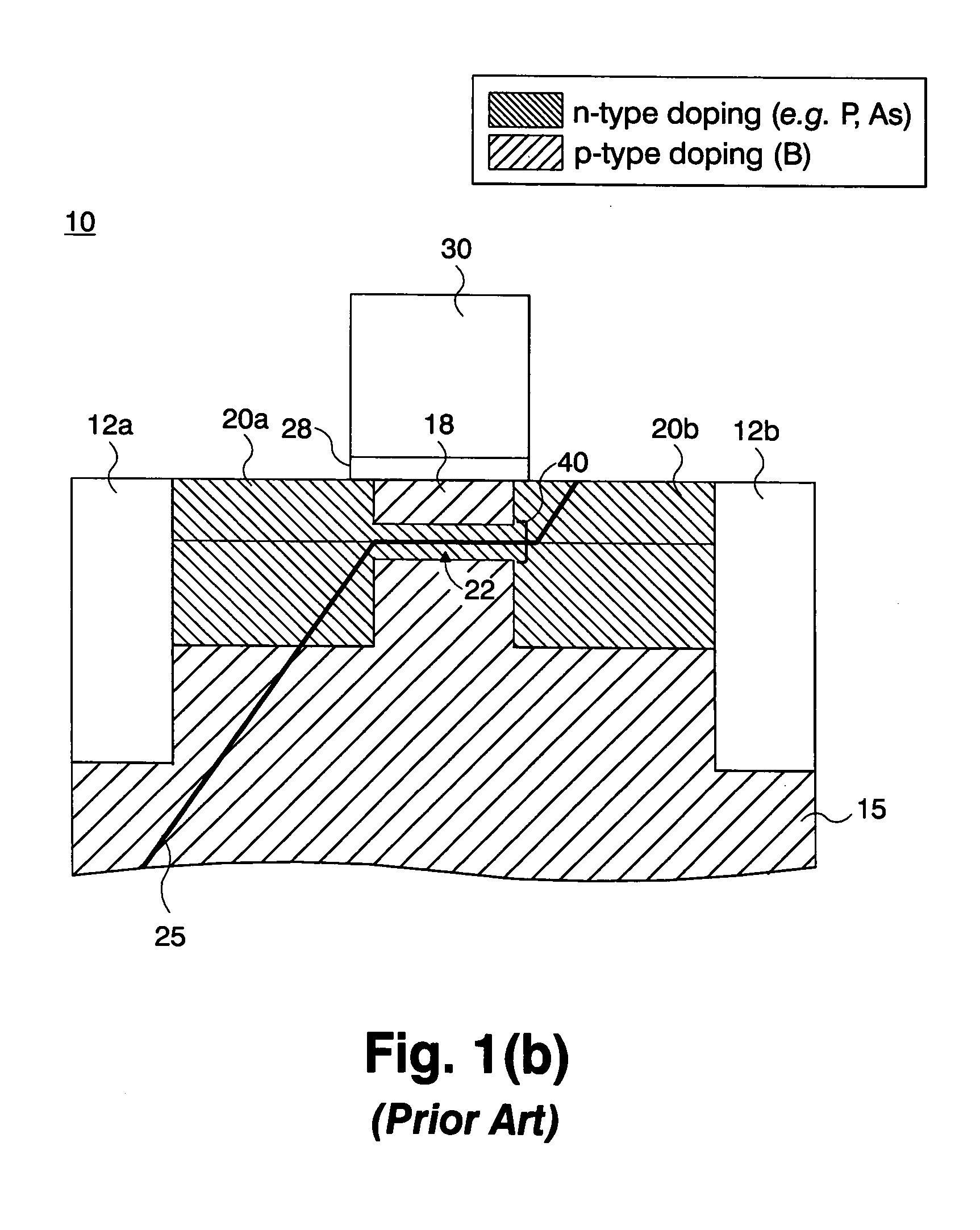

[0023]FIG. 3 is a cross-sectional diagram of the invention showing a strained Si n-MOSFET where a defect spanning from source to drain is partially occupied by heavy p-type dopants. Preferably, the strained-layer n-MOSFET includes a Si, SiGe or SiGeC multi-layer structure consisting of these materials, that has, in the region between source and drain, impurity atoms that preferentially occupy the dislocation sites so as to prevent shorting of source and drain via dopant diffusion along the dislocation. Advantageously, devices formed as a result of the invention are immune to dislocation-related failures, and therefore are more robust to processing and material variations. This invention relaxes the requirement for reducing the threading dislocation density in SiGe buffers, since the devices will be operable despite the presence of a finite number of dislocations.

[0024] In the preferred embodiment of the strained Si n-MOSFET depicted in FIG. 3, indium, In, is utilized as a blocking m...

second embodiment

[0025]FIG. 4 is a cross-sectional diagram of the invention showing a strained Si p-MOSFET device 200 where a defect spanning from source to drain is partially occupied by heavy n-type dopants. This device has the same structure as in FIG. 3, except that the source and drain electrodes 220 are p-type doped with boron, B, for example, the regions 210 between and below the source and drain regions are doped n-type. In the embodiment of the strained Si p-MOSFET depicted in FIG. 4, antimony, Sb, is utilized as a blocking material for boron, B, diffusion along the dislocation. That is, the region of the dislocation between the source and drain regions is partially occupied by Sb atoms 230 that act to block segregation of the source and drain dopant atoms along the dislocation, thus preventing a short between source and drain.

[0026]FIG. 5 is a cross-sectional diagram of a third embodiment of the invention showing a strained Si p-MOSFET device 300 having the same structure as either the dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com