Method for the production of an oxide ceramic shaped part and a part produced by such method

a technology of oxide ceramics and shaped parts, which is applied in the direction of ceramicware, impression caps, applications, etc., can solve the problems of long process time, required coating thickness of mixture ceramics, and security problems, and achieve cost-optimized production and improved aesthetic appearan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0053] A dry press granulate of ZrO2 powder is used for the raw material for the blank 10. It is doped with yttrium and comprises other components such as Al2O3. The dry press granulates can be, for example, those available from the TOSOH company with the commercial designation TZ-3YB and TZ-8YB and having a primary crystal size of 280-400 nm and a granulate size of 50 μm but, as well, can be the granulate available under the commercial designation of TZ-3Y20AB that is characterized by the addition thereto of 20% Al2O3 and that otherwise corresponds to the other granulates.

[0054] In accordance with the following table, powdery oxidized raw materials in predetermined mole portions are added to the zirconium oxide ceramics.

Raw MaterialTZ3YBTZ3YBTZ3YBTZ3YBTZ8YBTZ8YBTZ8YBOxideCeO2 / mol-%2.5581015——Er2O32.55—————CeO2 + Er2O3 / mol-%3 + 3——————Sc2O3 / mol-%3——————TiO2 / mol-%1015 ———1015

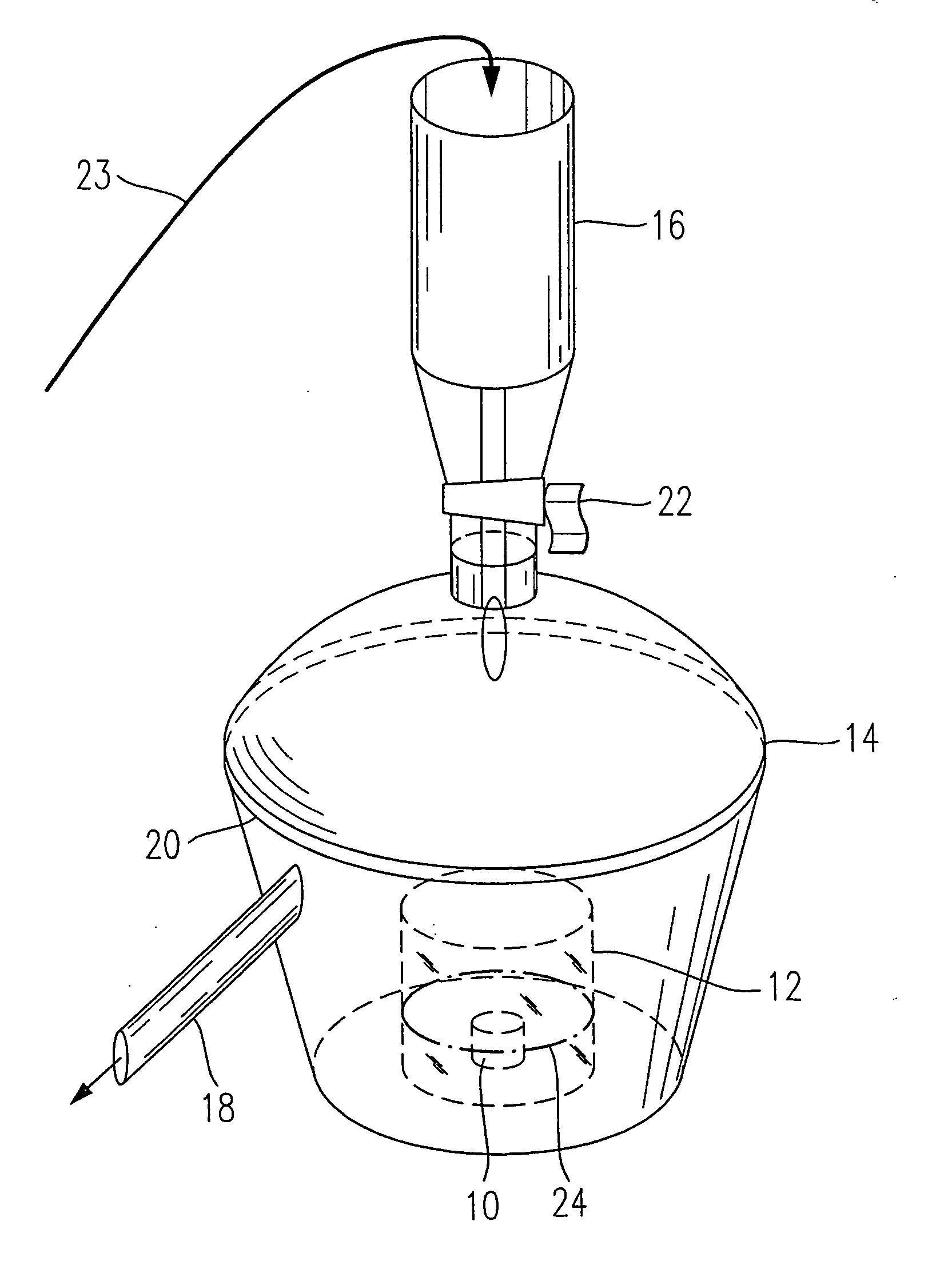

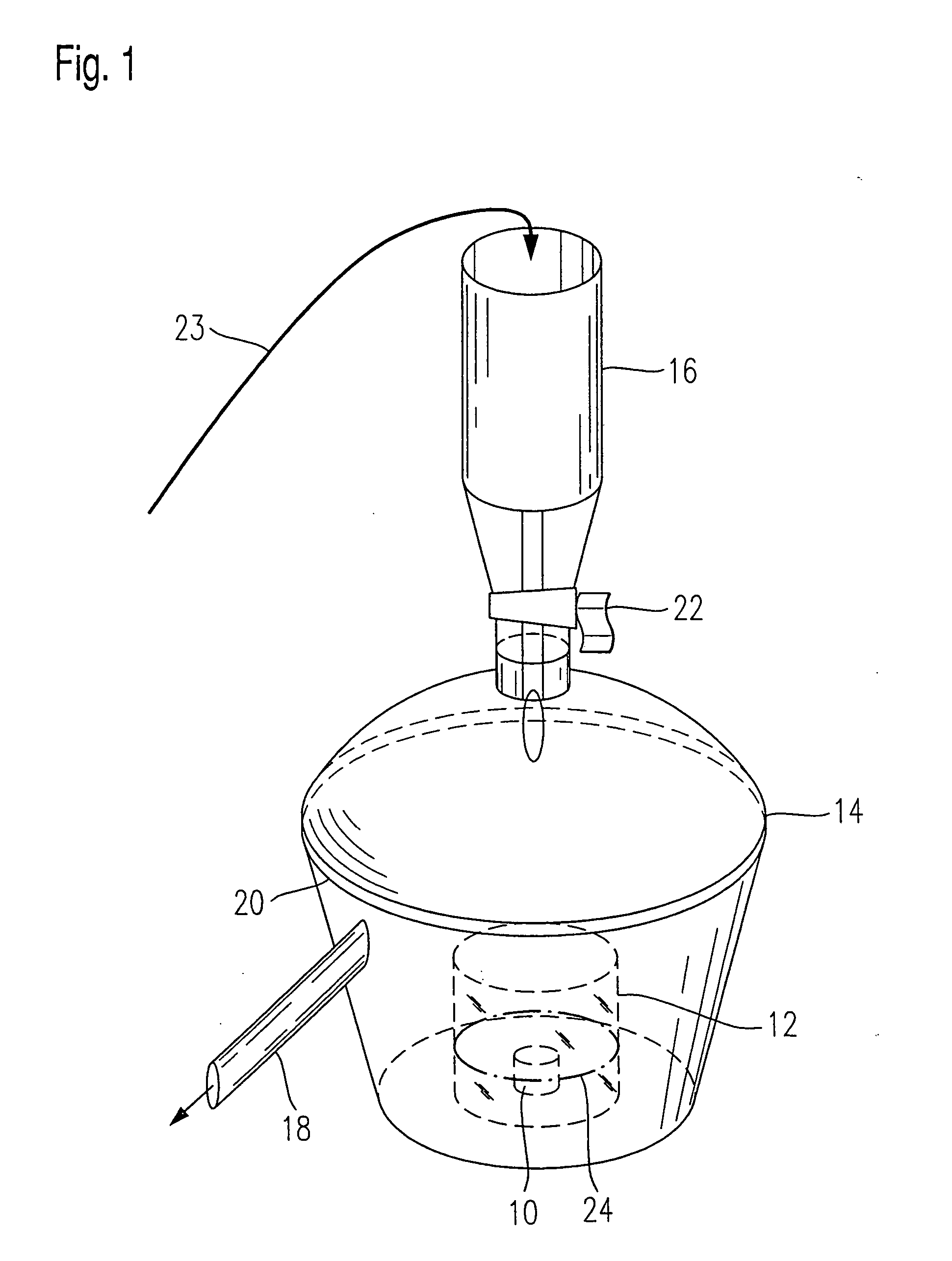

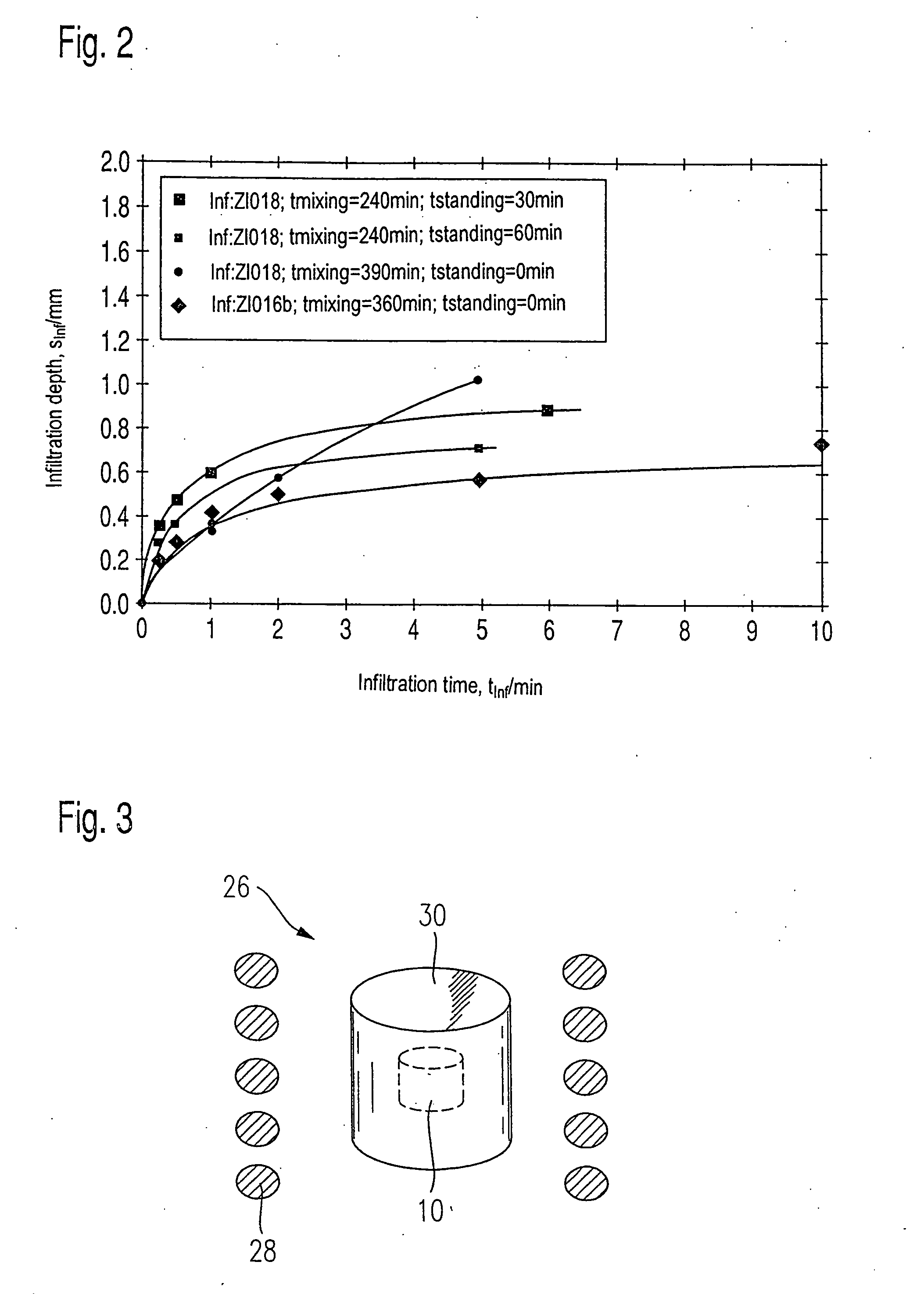

[0055] In this inventive experiment, cylindrical press forms with inner diameters of 12 and 16 mm were used...

example 2

[0072] In a modified example, in lieu of TEOS, a zirconium (IV) propylate (Zr(IV)Pr) was deployed. This zirconium (IV) propylate was used in lieu of TEOS and, when subjected to atmospheric pressure with water, was driven as zirconium oxide particles out of the pores of the blank. Also, in this connection, the pores could be closed, whereby the crystalline particles in the pores precipitate out, which corresponds to the actual base material. The thus achieved minimal coating thickness of the infiltration coating amounted to approximately 50 micrometers.

example 3

[0073] In total, the inventive process produced an oxide ceramic composite shaped part with high fracture strength, whereby the translucence properties corresponded to those of zirconium oxide ceramic (TZP) which are deployed in connection with the high-temperature isostatic press process.

DensityLightKic-Value(in theTransmission(Evans &Ptr / tInf. / (core) / CapabilityHV 10 / Charles) / SamplebarminVBr / Cg cm−3(comparison) %MPaMPa m1 / 2A12351000114806.0870.7——A12371000514806.1075.0——A1240100021480——132206.95A1245 90011480——130556.55A1246 900114806.0872.2——Mexoxitunknownunknownunknown6.0770.3128506.65Bio-HIPZeO2(comparisonmeasurement)Denzirunknownunknownunknown6.1076.4128306.70DO HIP-ZrO2(comparisonmeasurement)A1253 900Not14805.8856.4——infiltratedA1254 900Not1480——129006.17infiltrated

[0074] As can be seen in the foregoing, it is clear that the conventional sintered examples not produced in accordance with the present invention exhibit considerably worse properties with respect to light transmi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com