Soldering method of nonaqueous-electrolyte secondary-battery

a nonaqueous, electrolyte technology, applied in the direction of secondary cells, cell components, non-aqueous electrolyte cells, etc., can solve the problems of degradation or damage of batteries, difficult to secure a space for inserting soldering irons, etc., to prevent the damage of substrates, and prevent the degradation of battery characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

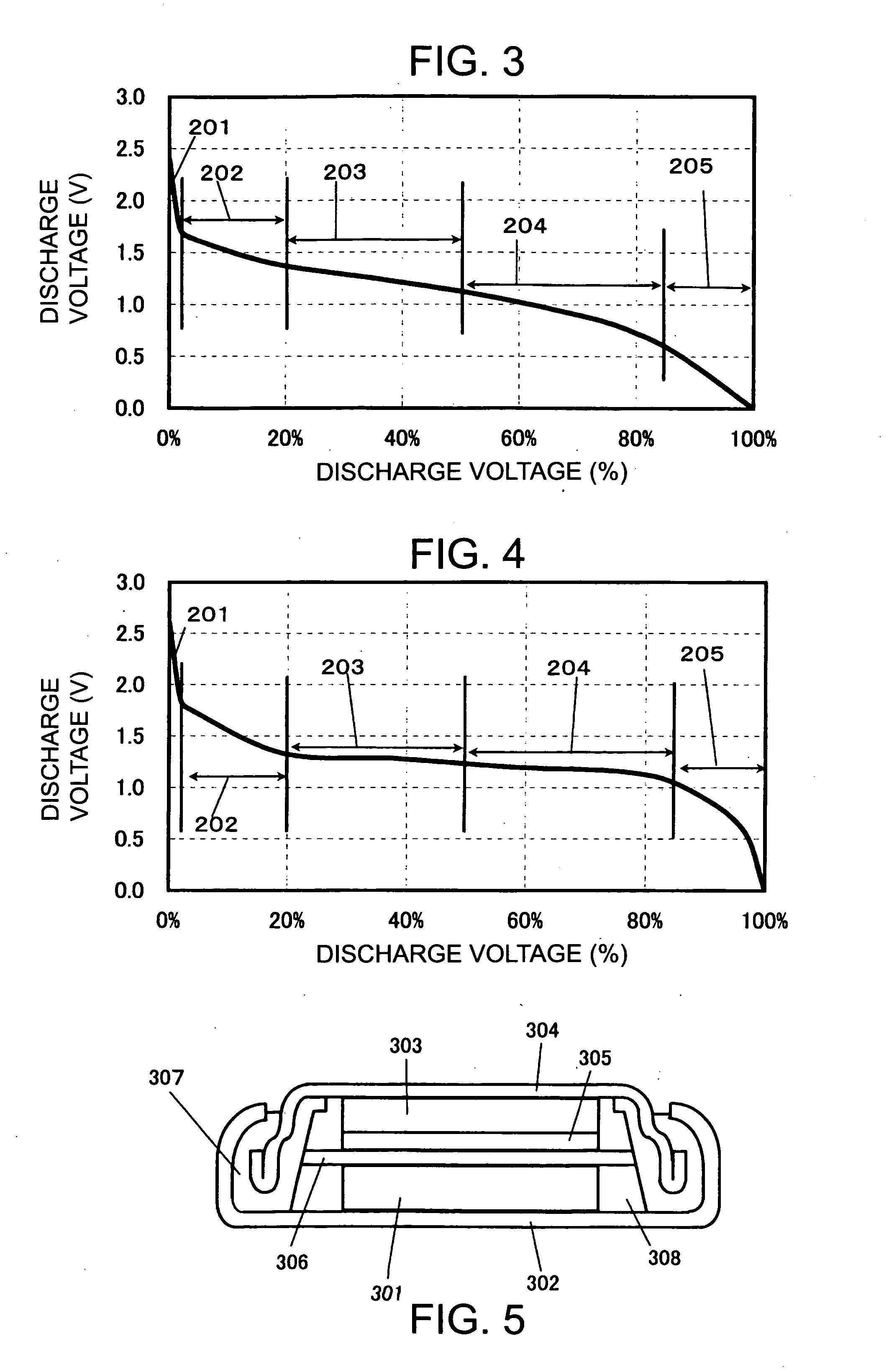

[0047] This embodiment is a case where Li4Ti5O12 is used as the active material for cathode and SiO as the active material for anode. A cathode, an anode, and an electrolyte prepared in a following way were used. The dimension of the battery was 4.8 mm in outer diameter and 1.4 mm in thickness. A cross section view of the battery is shown in FIG. 5.

[0048] In the first embodiment, the cathode was prepared in the following manner. Commercial Li4Ti5O12 was crushed, and then mixed with graphite as a conductive agent and polyacrylic acid as a binder in a weight ratio of Li4Ti5O12 / graphite / polyacrylic acid=85 / 13 / 2, thereby a cathode mixture was formed, and then the cathode mixture of 4 mg is pressed and molded into a pellet 2.4 mm in diameter at 2 ton / cm2. Then, the cathode pellet 301 obtained in this way was adhered to a cathode case 302 using a conductive resin adhesive containing carbon and integrated together (cathode unitization), and then subjected to drying by heating under reduce...

second embodiment

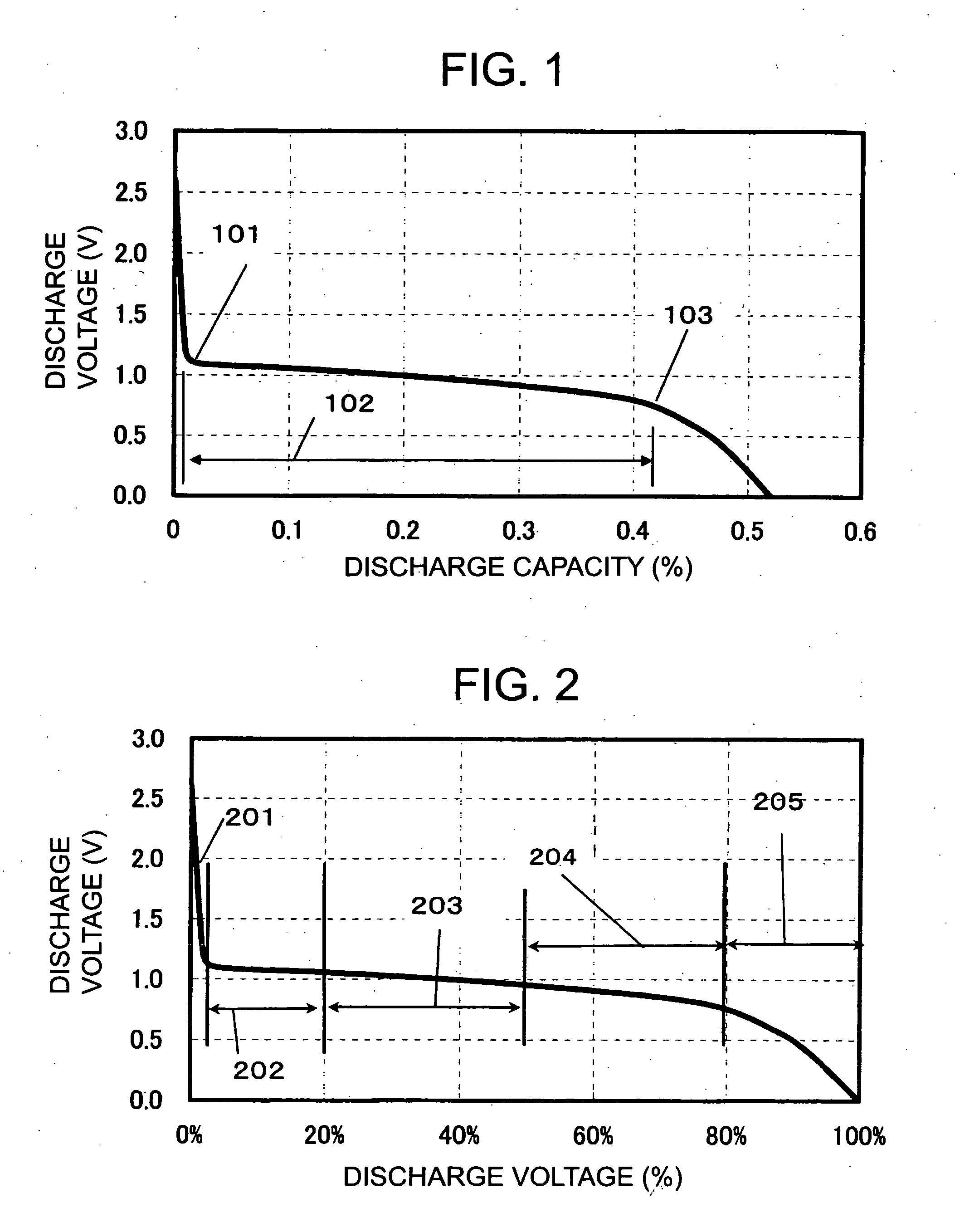

[0056] In this embodiment, Nb2O5 was used as the active material for the cathode, and as other components, the same components as the first embodiment were used, and a battery was produced similarly to the first embodiment.

[0057] The initial discharge curve of the battery was made in the same way as the first example. A graph as shown in FIG. 3 is a graph by plotting the discharge voltage (V) in ordinate and the discharge ratio (%) to the total discharge capacity of the secondary battery in abscissa. In FIG. 3, a region to the minimum value in the discharge curve was assumed to be a discharge region A201. Furthermore, the voltage plateau region 102 indicating the cell reaction was subdivided into three, and it was assumed that a region where discharge was performed beyond the discharge region A 201 in FIG. 2 to the discharge capacity of 20% was a discharge region B(1) 202, a region from the discharge capacity of 20% to 50% was a discharge region B(2) 203, and a region from the disc...

third embodiment

[0060] This embodiment employs Nb2O5 as the active material for cathode and a Li—Al alloy as the active material for anode. The cathode, in which Nb2O5 was used as the active material, was prepared according to the same procedure as the first embodiment.

[0061] For the anode, an Al sheet 2.9 mm in diameter and 0.10 mm in thickness was welded to an anode can by an ultrasonic welding. The anode can was dried and then pressed with a Li sheet 2 mm in diameter and 0.2 mm in thickness, thereby a Li—Al alloy anode was prepared.

[0062] For other components, the same components as the first embodiment were used, and a battery was produced in the same way as the first embodiment.

[0063] The discharge curve of the battery is shown in FIG. 4. The battery was subjected to the heating in the reflow oven at the maximum temperature of 240° C., and evaluated similarly to the first embodiment. However, in the measurement of the capacity, the battery was charged for 48 hours at the charging voltage of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com