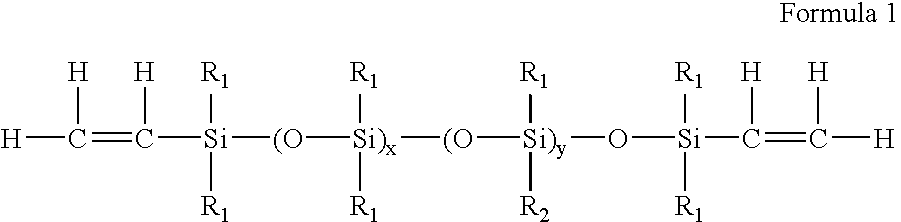

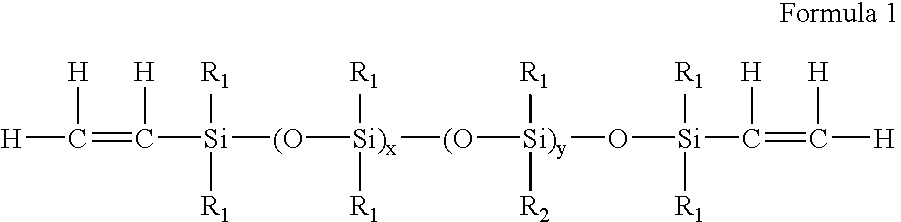

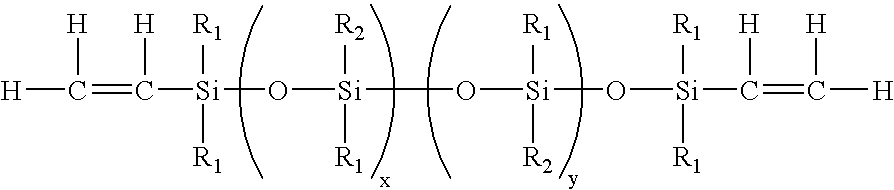

High refractive index polysiloxane prepolymers

a polysiloxane and high refractive index technology, applied in the field of high refractive index polysiloxane prepolymers, can solve the problems of increasing the incidence of postoperative complications, less popularity of more rigid iol implants in the market, and difficulty in incorporating a quantitative amount of all-aromatic cyclics into the growing polymer molecule, etc., to achieve high refractive index, easy removal, and high elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Viny-Terminated Polydimethylsiloxane of Low Molecular Weight

[0027] A 3-neck, 500 mL round bottom flask connected with a reflux condenser and nitrogen inlet tube, was charged with 1,1,3,3,5,5,7,7-octamethyltetrasiloxane (43.73 g), 1,3-divinyltetramethyldisiloxane (1.39 g) and aminosilanoate (0.48 g), all from Gelest, Inc., Tullytown, Pa. The contents were stirred under nitrogen and heated with an oil bath at 80 to 90° C. After 16 hours, the contents were heated to 140° C. to decompose the amine catalyst. Yielded 23.9 g of product. SEC gave Mn of 8,600 Da and Mw of 13,300 Da.

example 2

Preparation of Viny-Terminated Polydimethylsiloxane-co-Methylphenylsiloxane with a Total of 10 Percent Phenyl

[0028] A 3-neck 500 mL round bottom flask connected with a reflux condenser and nitrogen inlet tube, was charged with 1,1,3,3,5,5,7,7-octamethyltetrasiloxane (29.98 g, 0.1043 mole), vinyl-terminated polydimethylsiloxane from Example 1 (4.51 g), 1,3,5,7-tetramethyl-1,3,5,7-tetraphenyltetrasiloxane (15.48 g, 0.0285 mole) and 40 mL of toluene. The contents were heated under nitrogen at 90° C. to distill off 12 mL of azeotrope with any water contaminant. Then 0.42 g of amine silanoate was added and the contents were heated for three hours under nitrogen blanket. After the heating, the reaction product mixture was added to 200 mL of ether and extracted twice with 30 mL of 0.05 N HCl, and then extracted twice with 20 mL of 0.05 N sodium bicarbonate. After removal of solvent, the product (45 g) was found to have Mn of 28,000 Da, Mw of 74,400 Da by SEC. The product had 26 percent by...

example 3

Preparation of Viny-Terminated Polydimethylsiloxane-co-Methylphenylsiloxane with a Total of 10 Percent Phenyl

[0029] The preparation was repeated using the same procedure as that described above in Example 2 except that the contents were refluxed for 16 hours instead of three hours. The final product had an Mn of 30,100 Da, Mw of 96,300 Da and had 21.5 percent of cyclics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Polymeric | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com