Periodic interleaved star with vias electromagnetic bandgap structure for microstrip and flip chip on board applications

a technology of interleaved stars and flip chips, applied in cross-talk/noise/interference reduction, waveguide devices, printed circuit aspects, etc., can solve problems such as unique electromagnetic resonance and emission packaging problems, potential formation of electromagnetic boundaries, and degradation of semiconductor performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

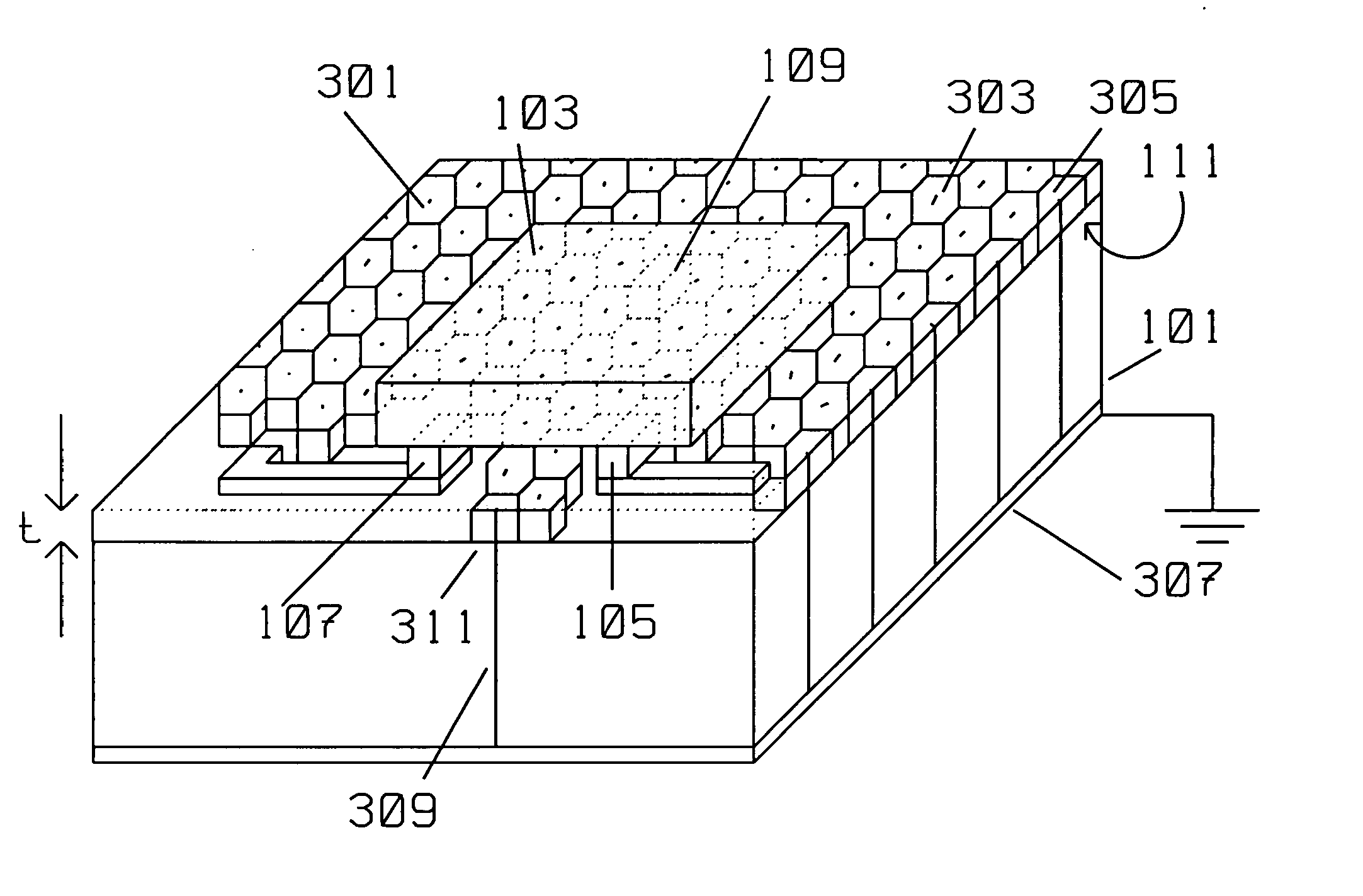

[0025] The present invention describes an apparatus and method for improved cross talk suppression in a hybrid assembly by incorporating a single layer made of electromagnetic band-gap (EBG) stars on a hybrid substrate such as, for example, alumina, LTCC (low temperature co-fired ceramic) as well as HTCC (high temperature co-fired ceramic).

[0026] The EBG stars reduce the cross talk induced by undesired surface / waveguide modes at high operating frequencies (10 to 20 Ghz) between input / output and power (or ground) pins on the operation of the hybrid.

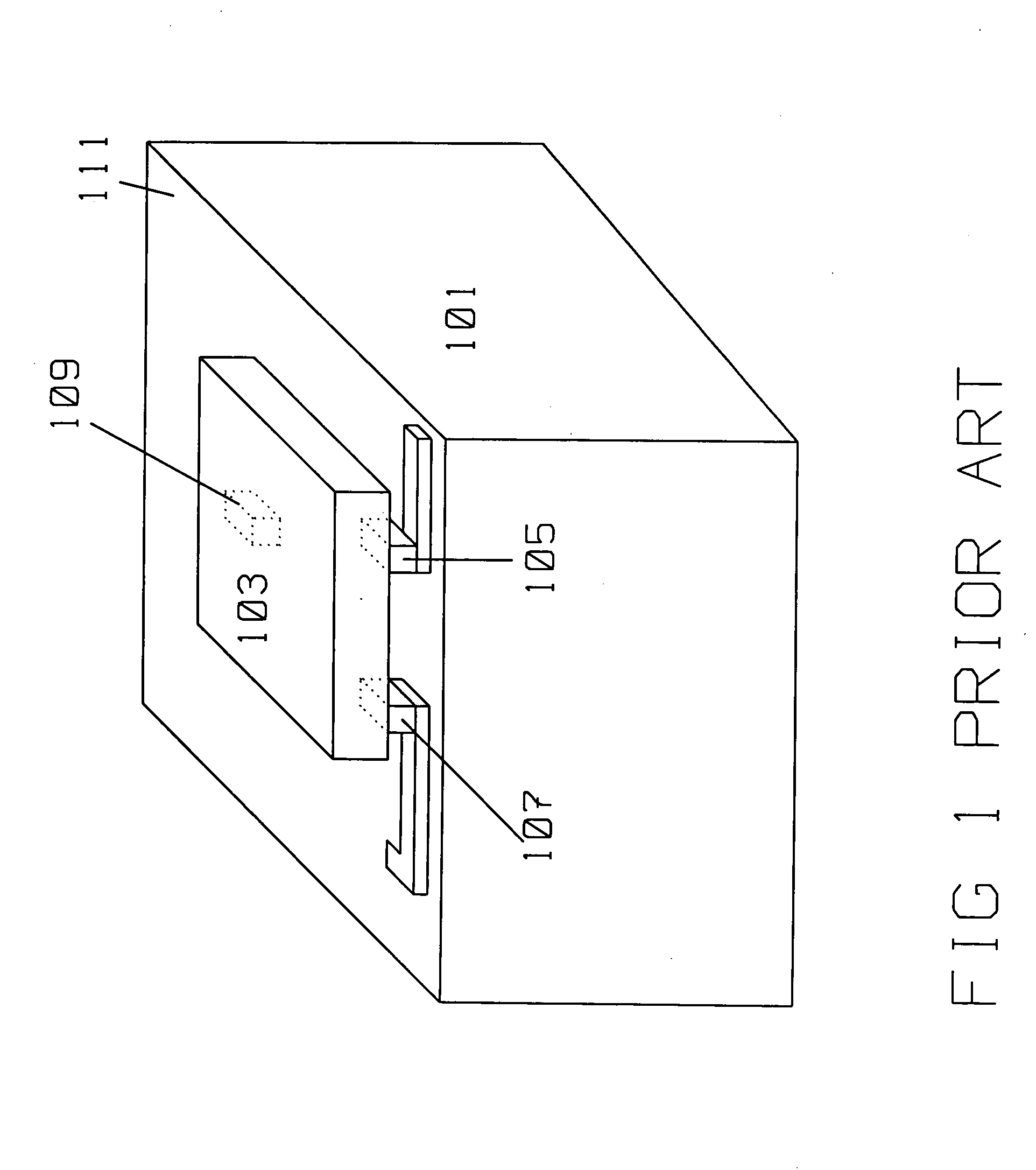

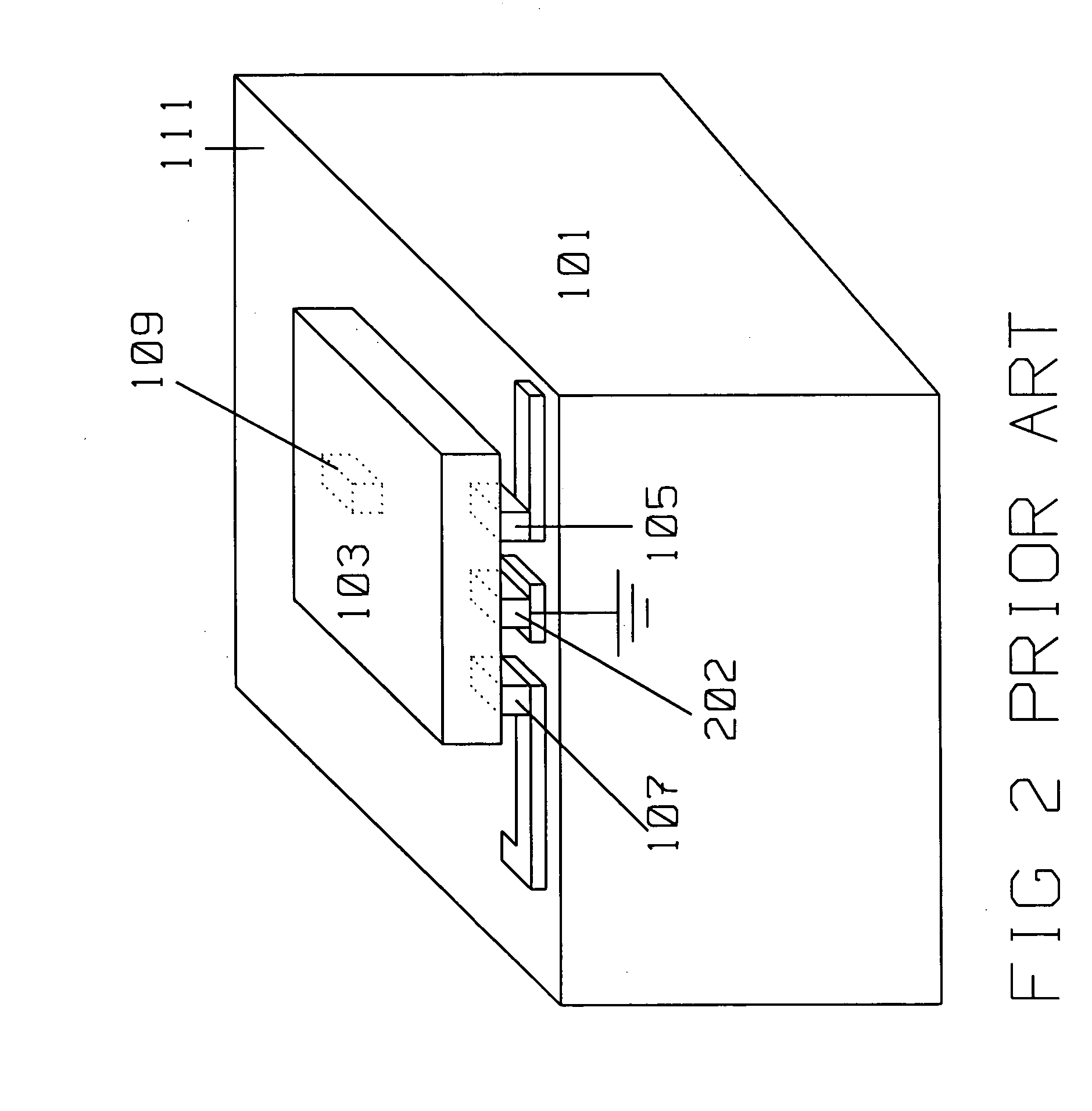

[0027]FIG. 1 is a typical configuration of a hybrid of the prior art where a semiconductor structure 103 is mounted on the upper surface 111 of a host substrate 101 using bumps 105, 107 and 109 for inter-connection means. Substrate 101 has an upper metalization layer deposited on upper surface 111 of substrate 101. Conductive paths 113 and 115 are etched from a metalization layer, and interconnect bumps 105, 107 and 109 to their respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com