Precipitation hardened martensitic stainless steel, manufacturing method therefor, and turbine moving blade and steam turbine using the same

a technology of precipitation hardening and martensitic stainless steel, which is applied in the direction of machines/engines, furnaces, heat treatment apparatus, etc., can solve the problems of delayed crack generation, difficult to obtain fine grain structure, and insufficient strength of nb or ti alone of background art, etc., to achieve high reliability, reduce cost, and increase the strength of the blade groove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

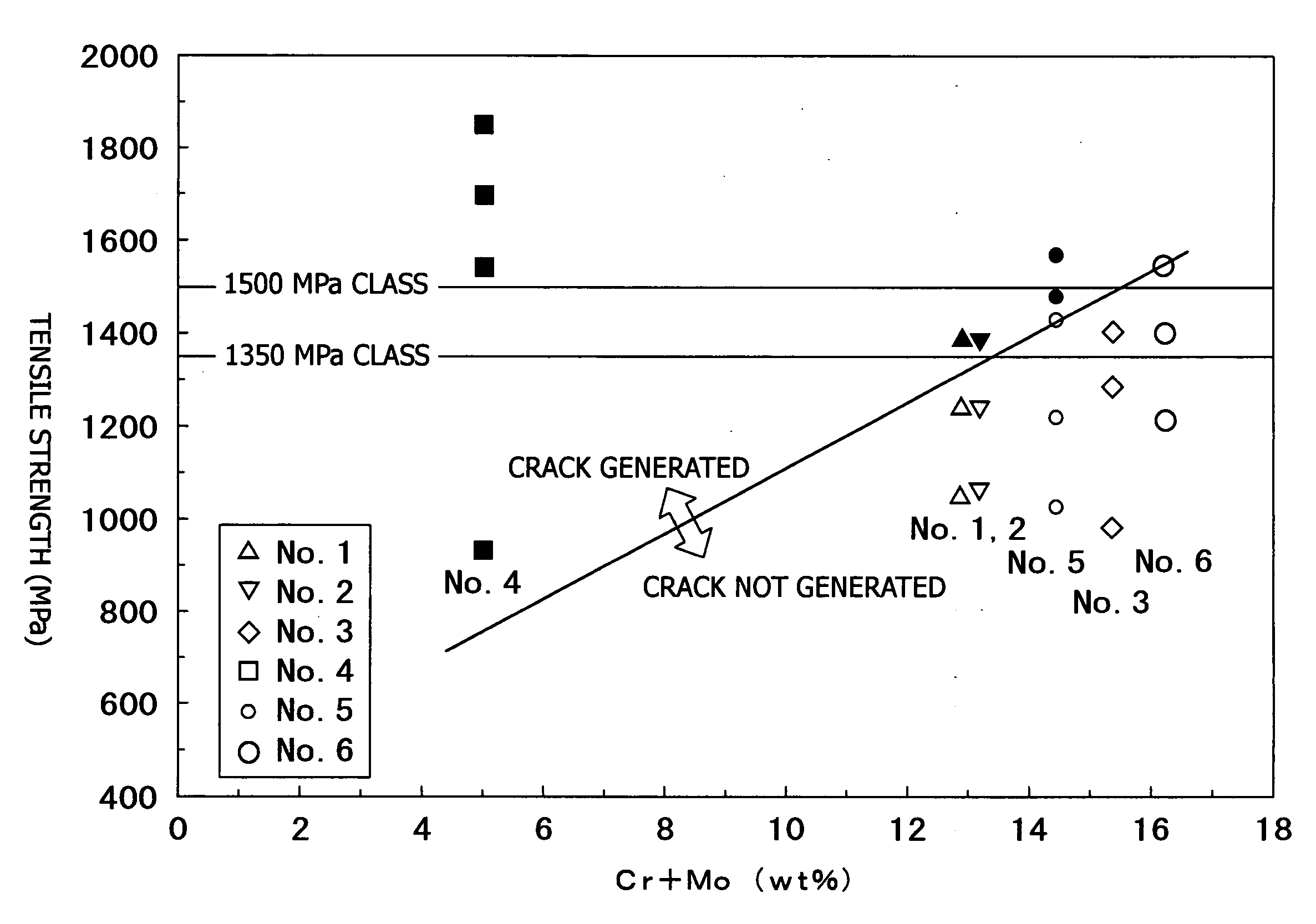

[0053] Hereunder, the present invention is explained based on examples. Table 1 gives the chemical composition (wt %) of a high-strength steel relating to a material for steam turbine long blade. In Table 1, the balance consists of Fe and unavoidable impurities. After being subjected to 50 kg high frequency vacuum melting, each sample was hot forged into a square bar or round bar, and was subjected to the following heat treatment.

TABLE 1Chemical composition (wt %)Sample No.CrNiMoCSiMnPSNb + TaNAlVOther steel111.942.540.990.120.050.030.0010.0020.050.016—0.20type211.802.511.460.110.030.010.0010.0010.050.017—0.21315.394.21—0.040.270.430.0260.0030.230.035——4—18.505.040.030.100.010.0030.001——0.07—Steel of this512.348.472.150.040.070.040.0030.0040.010.0041.10—invention614.038.352.160.040.060.040.0050.0040.010.0051.28—712.398.452.140.030.060.050.0030.0040.010.0051.36—812.398.452.140.040.070.040.0020.0020.010.0031.52—912.378.452.140.040.080.040.0020.0020.010.0061.72—1012.378.342.130.030.0...

example 2

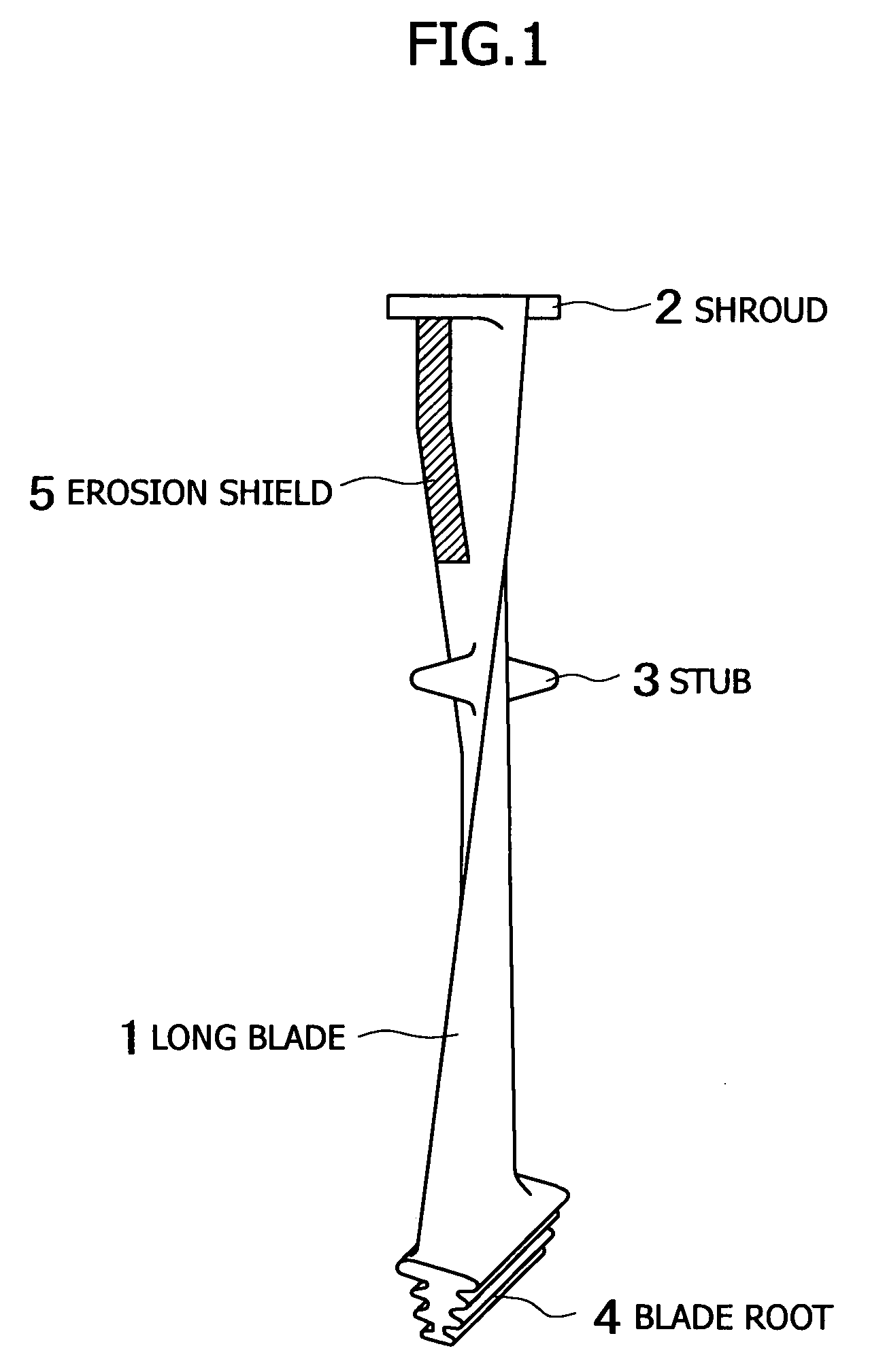

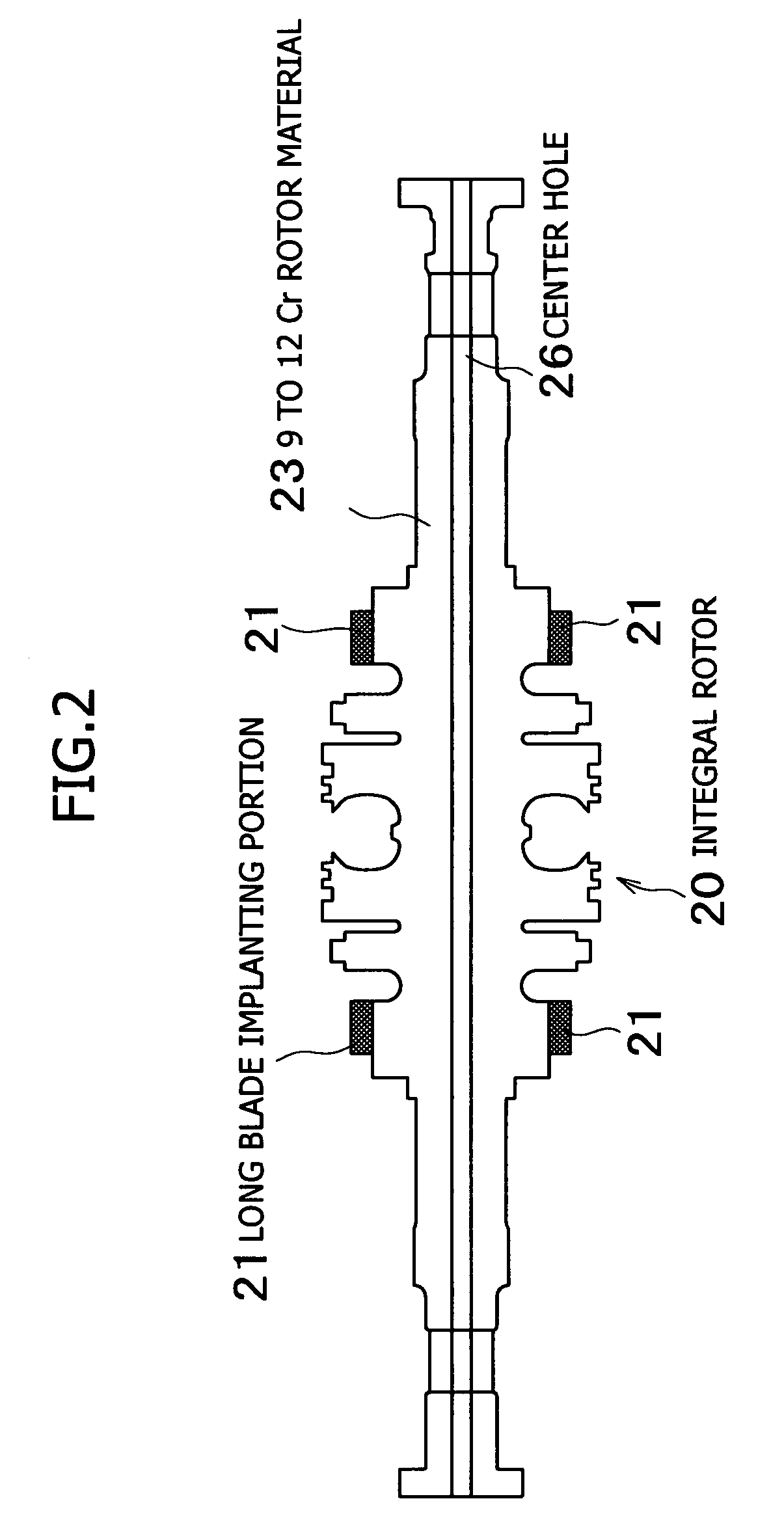

[0067] Hereafter is described a procedure by which the long blade having a 45-inch class blade length (for the steam turbine of 3600 rpm) shown in FIG. 1 was manufactured by using the steel having the chemical composition of sample 6 shown in Example 1. First, a steel having the chemical composition of sample 6 was subjected to vacuum induction melting, and then subjected to vacuum arc remelting, by which a round bar shaped raw material with a diameter of about 200 mm was manufactured by hot forging. Subsequently, the raw material was subjected to rough cogging so as to form a shape of dumplings on a skewer, the shape having different diameters according to the thickness of each portion of the blade root etc., and was formed into a near-net shape by die forging after being heated to a high temperature, thereafter being subjected to heat treatment. For the heat treatment, after heating was performed at 925° C. for 2 hours, forced air cooling was performed, and solution heat treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| toughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Charpy absorbed energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com