Soluble deverting agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Prophetic Example

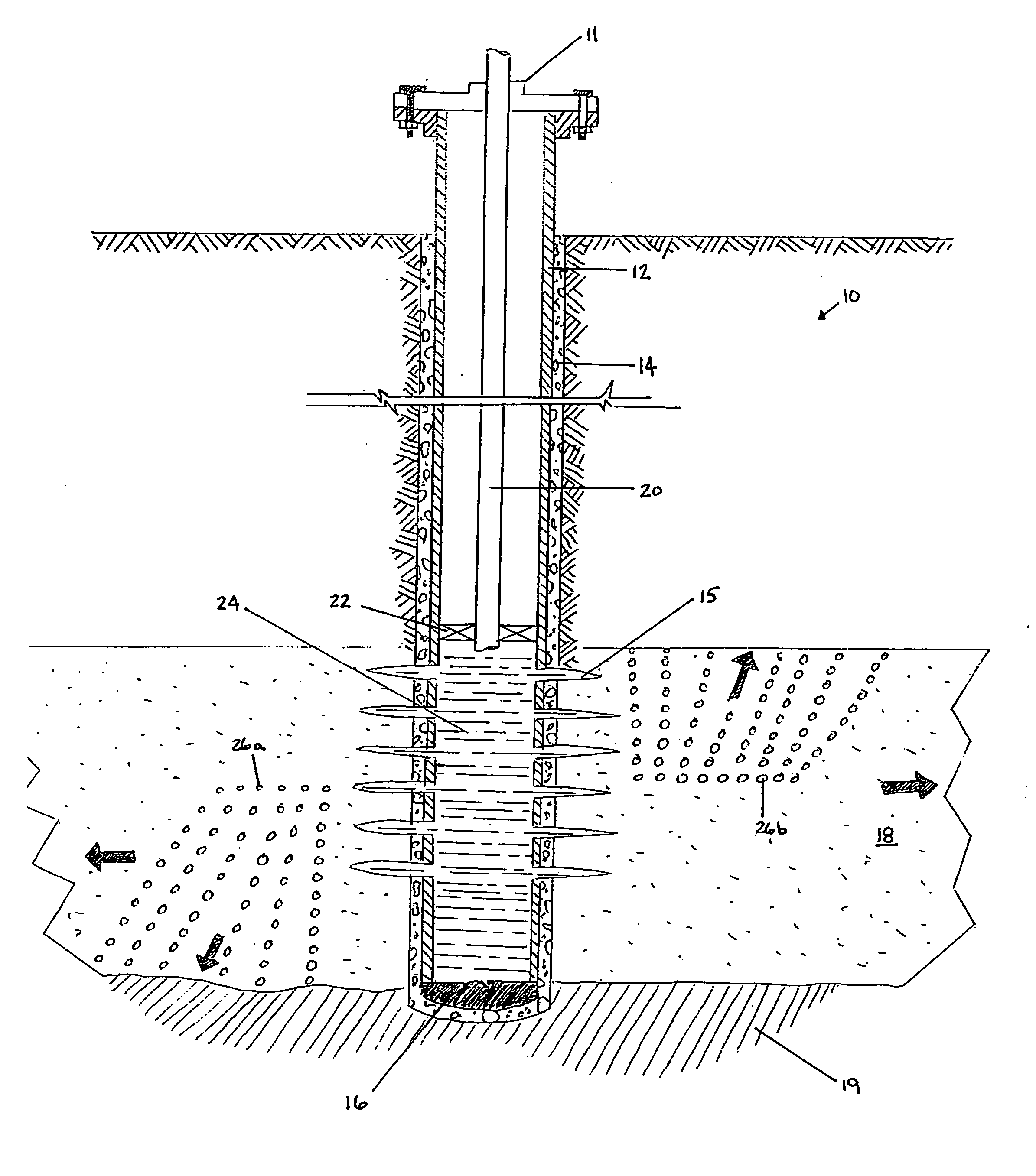

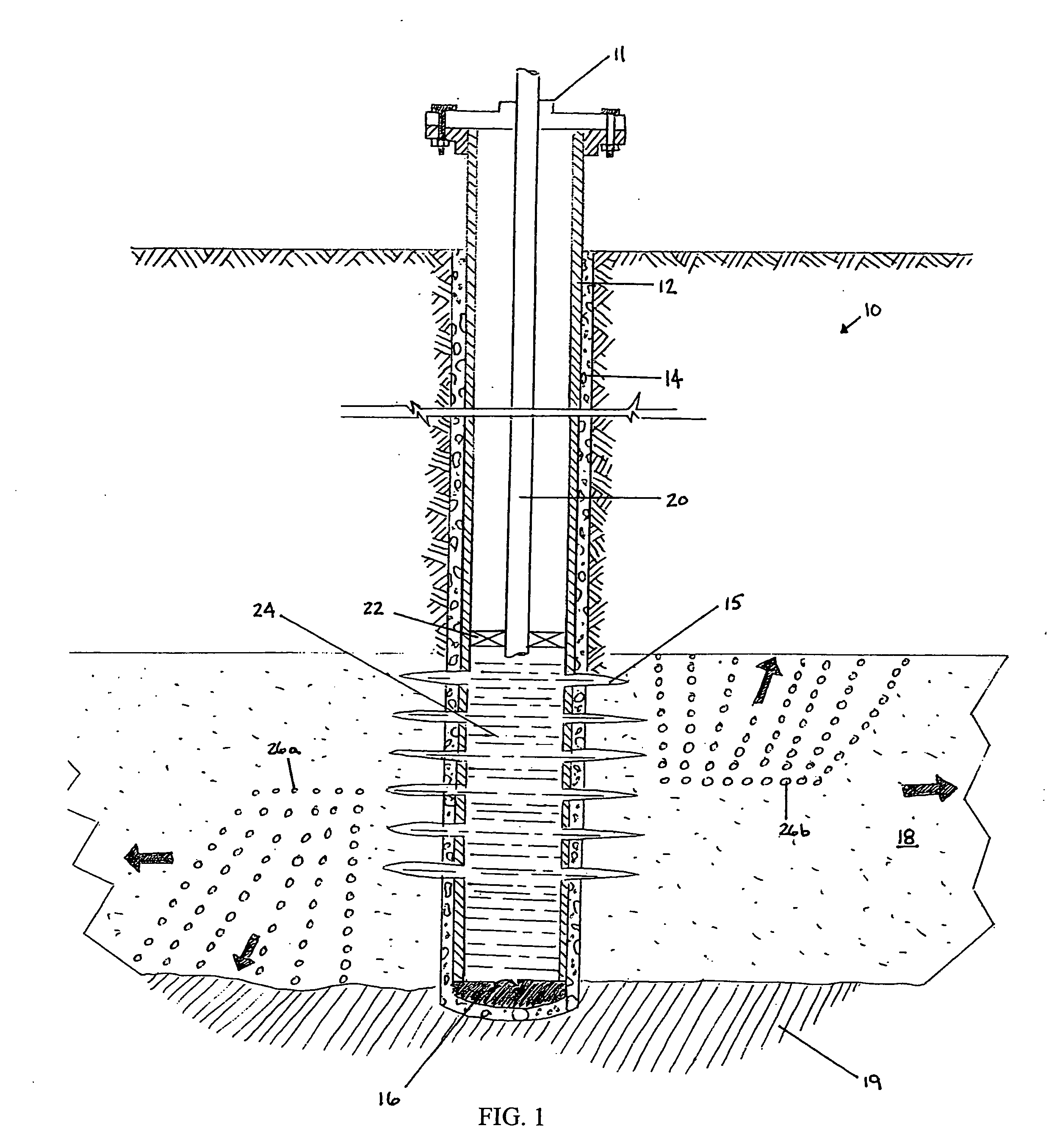

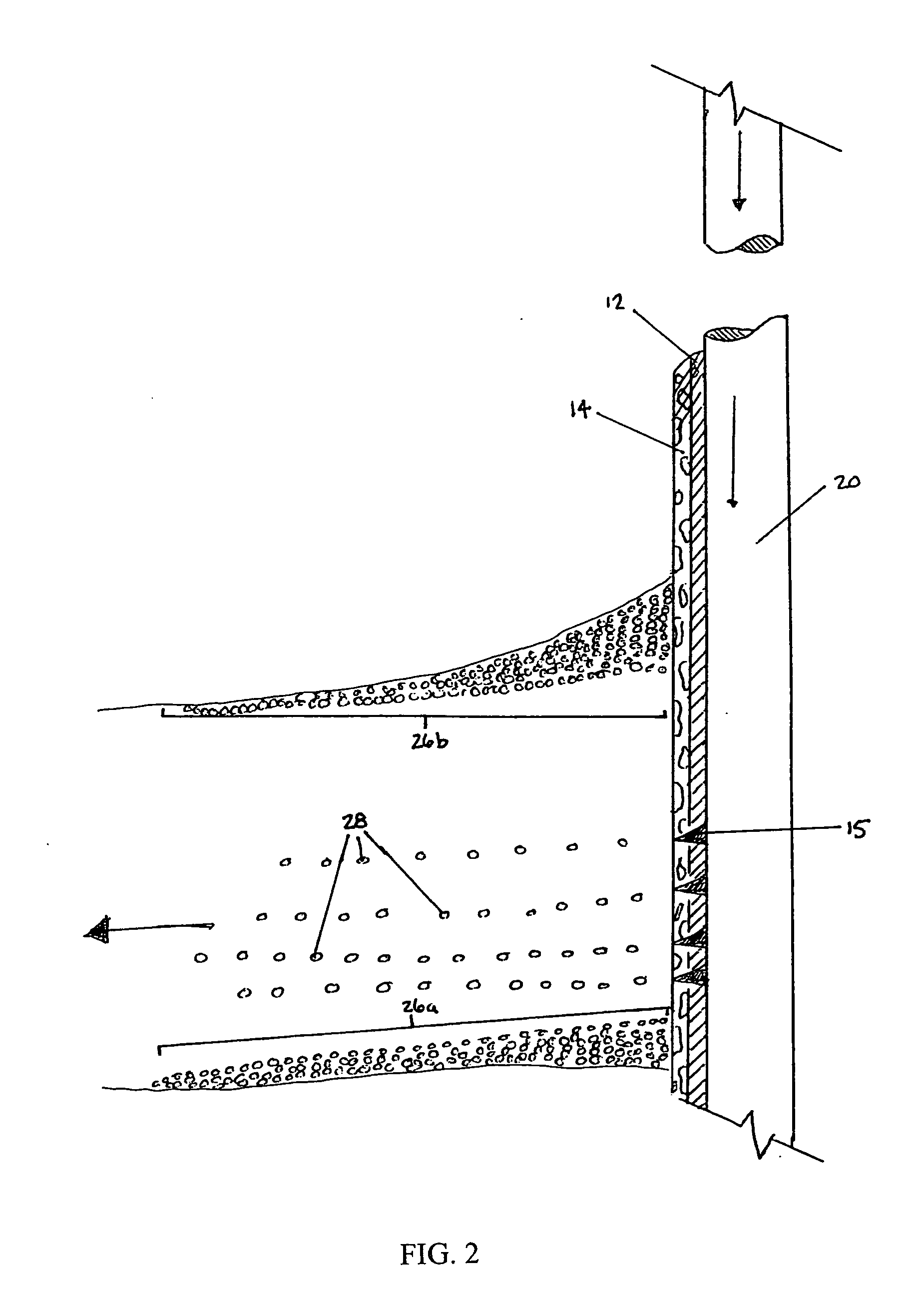

[0089] The following prophetic example describes a method of how the soluble coating on the propping agent or agents of the present invention can be used to divert fracture growth and extend the fractures into the productive zone of an oil or gas well. The primary purpose of the soluble coated proppant is to define an upper and lower boundary in the hydraulically generated vertical fracture so that the main direction of growth continues to extend outward in length away from the wellbore. This additional length of the conductive fracture aids in draining additional areas of the productive formation, allowing oil, gas, and / or water recovery production to be improved and greater flow rates to be established as a result of longer fracture length.

[0090] The following steps can be followed, using the soluble coated proppant materials of the present invention.

[0091] 1. A fracture injection rate is established with a low viscosity fracturing fluid.

[0092] 2. A soluble co...

example 2

Procedure for determining the rate and degree of polymer dissolution

[0101] Sand substrate was coated with various water-soluble polymers:

Chemical NameTrade NameSupplierPoly(ethylene) oxideWSR 80Dow ChemicalsPoly(propylene) oxideWSRN 750Dow ChemicalsPoly(proplylene) oxideUCAR309Dow ChemicalsPoly(lactic acid)PLA6551-DE&M specialtiesPoly(lactic acid)PLA5600E&M specialtiesPoly(vinylacetate / alcohol)PVA / HydroleneIdroplax Inc.Collagen 1Glue 512Milligans and HigginsCollagen 2GM BondHormel foods

[0102] Thereafter, the following test procedure was used to determine rate and degree of solubility:

[0103] Determine the total mass of the polymer on the sand by regular LOI procedure. Add 500 grams of coated sand in 1 liter of water. Take a 400 mm filter paper and weight it on an analytical balance up to 4 decimal places. Prepare vacuum filtration apparatus by using 400 mm filter paper, perforated ceramic funnel, 2 liters Erlenmeyer flask with side opening connected to the vacuum pump by a rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com