Optoelectronic probe

a technology of optoelectronic probes and probes, applied in the direction of liquid/fluent solid measurement, peptides, test/measurement of semiconductor/solid device, etc., can solve the problems of difficult analysis of impedance spectroscopy and extreme complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following description is of the best mode presently contemplated for the carrying out of the invention. This description is made for the purpose of illustrating the general principles of the invention, and is not to be taken in a limiting sense. The scope of the invention is best determined by reference to the appended claims.

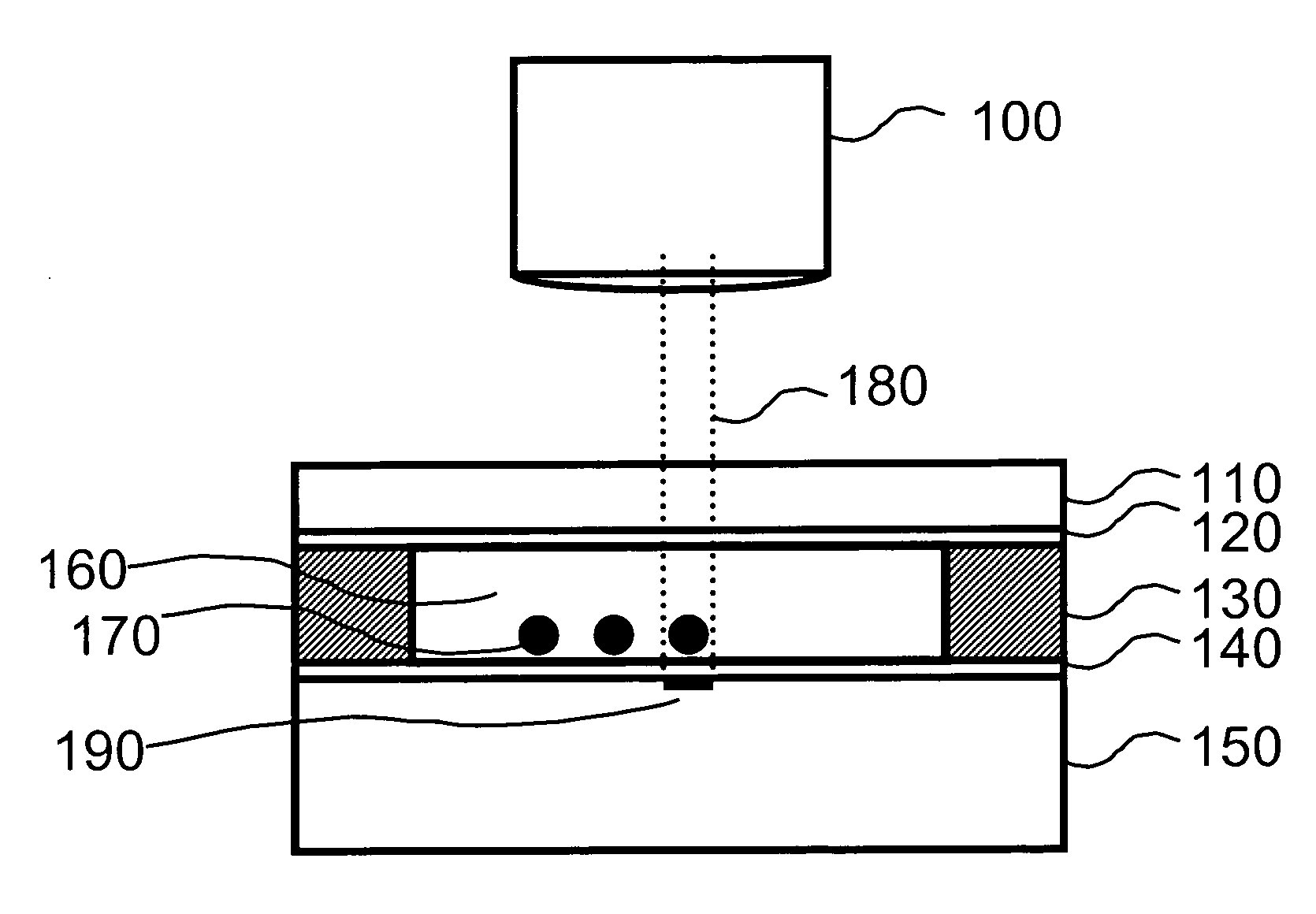

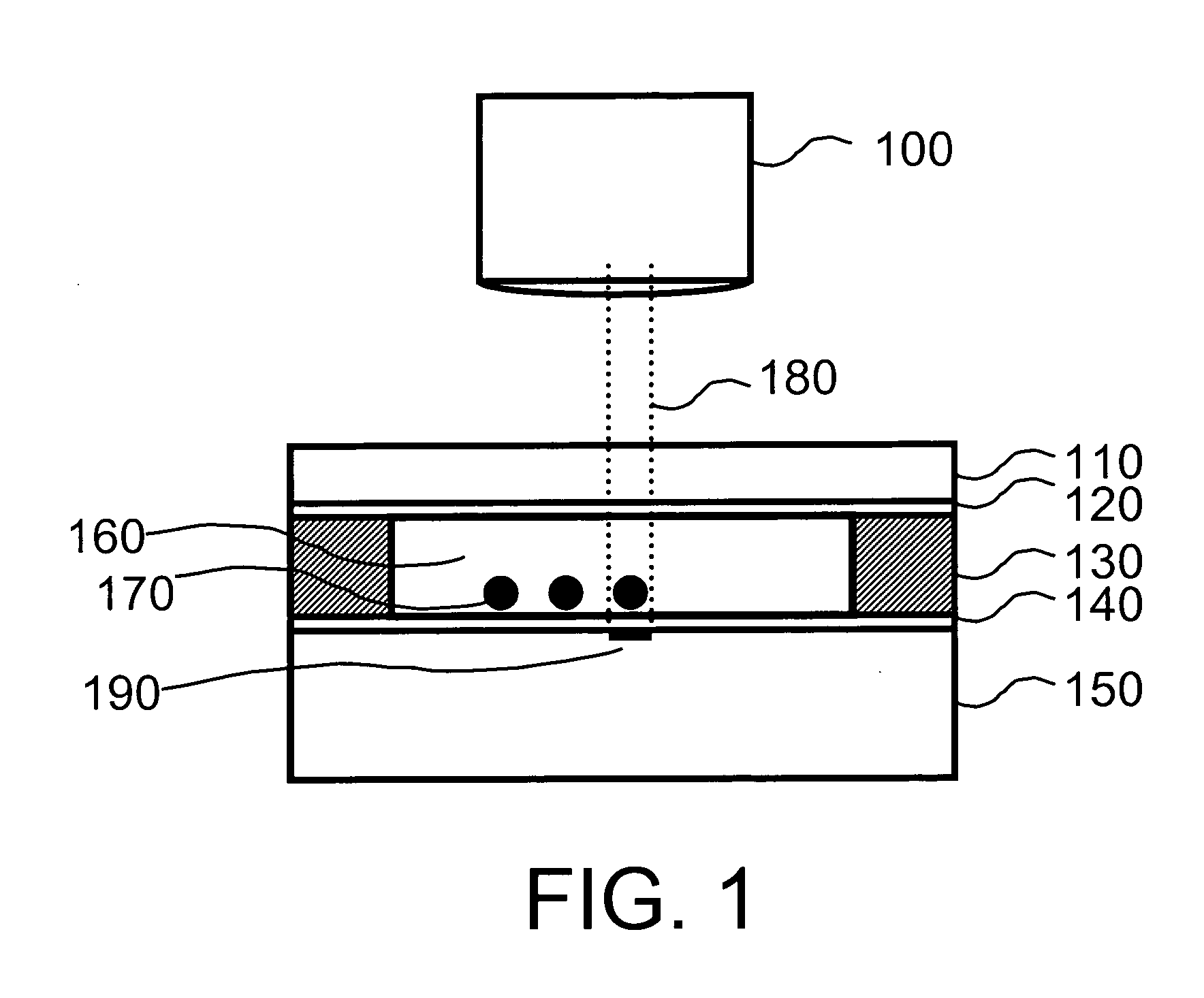

I. Optoelectronic Probe

[0043]FIG. 1 is a sectional view of an embodiment of the present invention. An optical microscope, represented by reference number 100, can be used to observe and record the particle manipulation process. The top electrode of the “sandwich” electrochemical cell is formed by a glass slide 110 coated by an optically transparent conducting thin film, such as indium tin oxide (ITO) 120. This kind of transparent conducting electrode is commercially available. A spacer (typically thick ˜50 μm), represented by reference number 130, is formed by polymer film with a hole in the center. Reference numeral 140 denotes a layer of thin ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com