Rotating body dynamic quantity measuring device and system

a dynamic quantity and measuring device technology, applied in the field of measuring systems, can solve the problems of high cyclic deformation, high cyclic fatigue, and difficult to maintain reliability of wire strain gauges, and achieve the effects of not fatigued, not corroded, and high reliability of measuremen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

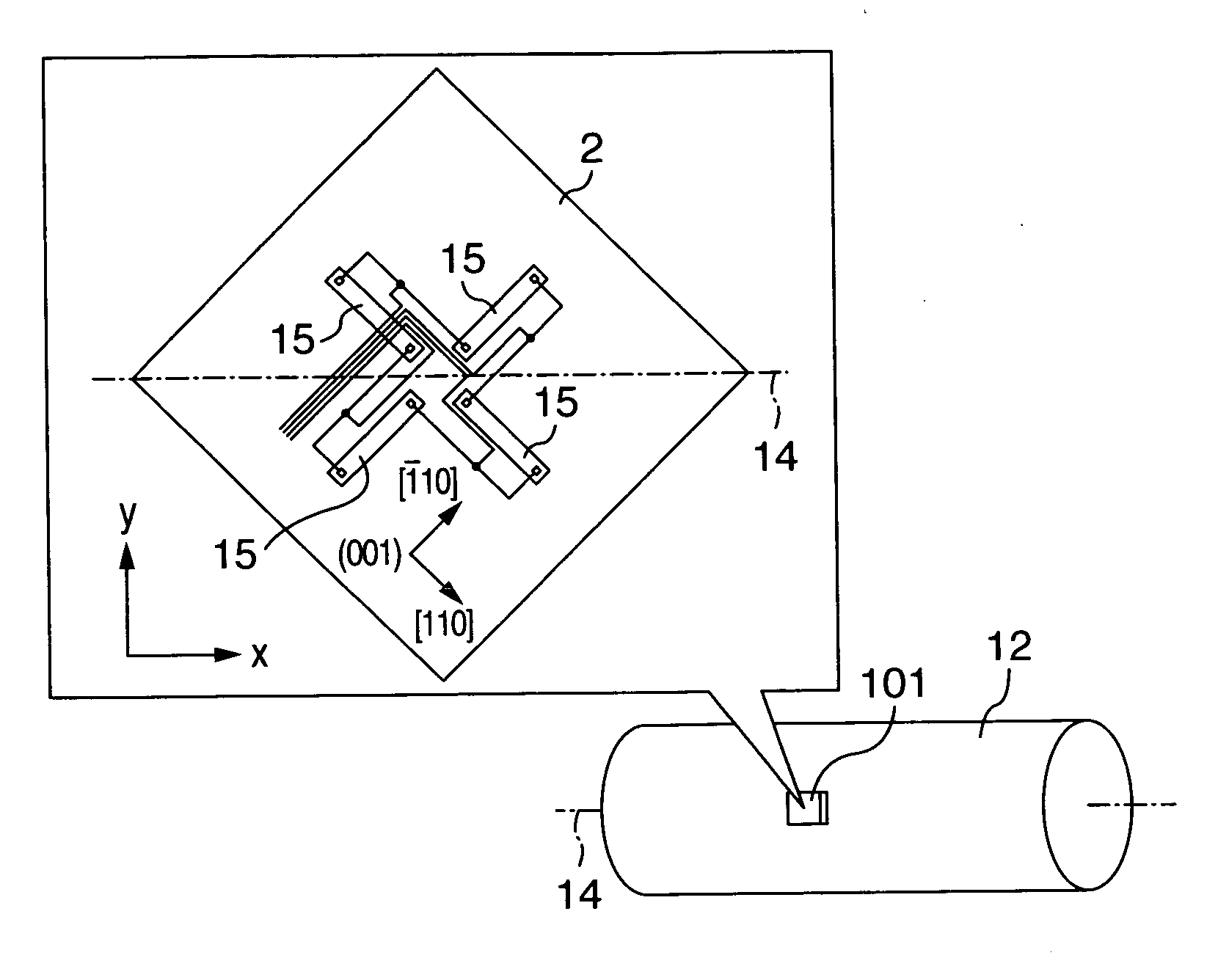

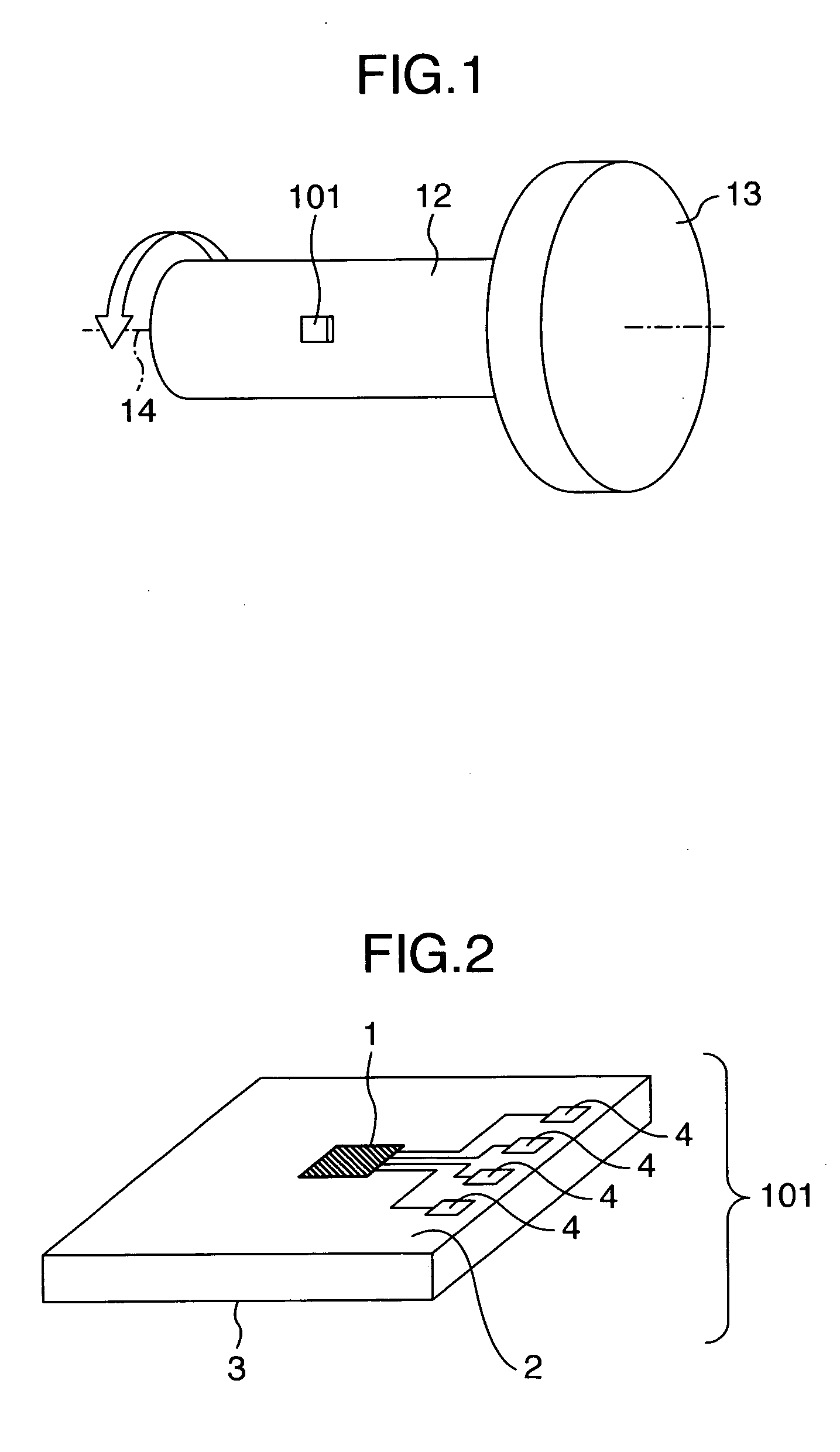

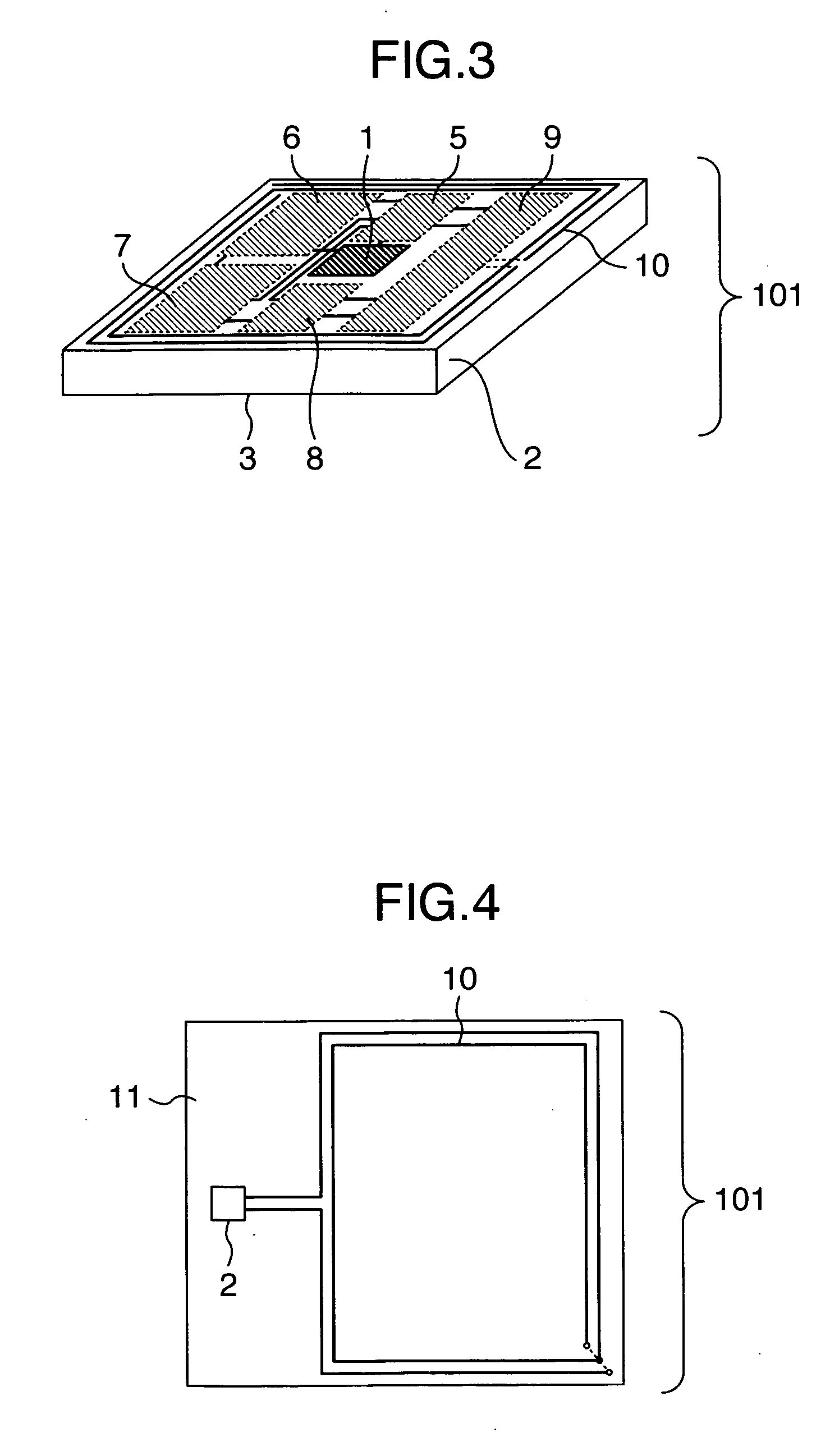

[0044]FIG. 1 shows a construction of a rotating body dynamic quantity measuring system in a first embodiment of this invention. A rotating body dynamic quantity measuring device 101 is installed on a surface of a rotating shaft 12 to measure a torque of the rotating shaft 12 as the shaft 12 rotates about a rotating center 14. The rotating body dynamic quantity measuring device is formed of a single crystal silicon shaped like a square chip which measures several hundred microns to several millimeters in one side and ten microns to several hundred microns in thickness. A back of an element forming surface or a diffusion layer is bonded to the rotating shaft 12 to measure its strains. Normally, in measuring the torque of the rotating shaft, a strain gauge formed of a metal foil is used. However, the metal foil used in the strain gauge has a short fatigue life. So when attached to a rotating shaft that undergoes high cycle deformations, the metal foil cannot withstand a long period of ...

embodiment 2

[0054] The rotating body dynamic quantity measuring device 101 of this invention is manufactured by forming minute, thin film structures several microns in size on the silicon substrate several millimeters square using the semiconductor fabrication process. So it is difficult to visually identify the diffusion layer in the rotating body dynamic quantity measuring device 101. The sensor of this invention considers the direction in which a strain is measured, the crystal orientation, and the direction in which the impurity diffused resistors are arranged. Therefore, what matters in the site of actual use of the rotating body dynamic quantity measuring device 101 is how the device is arranged with respect to the direction in which a strain is to be taken. So, as shown in FIG. 21, a mark 17 is formed in the rotating body dynamic quantity measuring device 101. FIG. 21 shows a rotating body dynamic quantity measuring device using a bridge circuit of a p-type diffusion layer on which an ar...

embodiment 3

[0055]FIG. 25 shows a third embodiment of the rotating body dynamic quantity measuring system according to this invention. FIG. 25 schematically shows the rotating shaft 12 as seen from the end, on the circumferential surface of which is attached a plurality of rotating body dynamic quantity measuring devices 101 with a wireless communication function. Radio waves transmitted from the rotating body dynamic quantity measuring devices 101 are received by a receiving antenna 18 and converted by a receiving unit 19 into strain and torque values. When the rotating shaft 12 is formed of a conductive body such as metal, radio waves do not easily travel to the far side of the shaft. To cope with this problem, this embodiment has a plurality of rotating body dynamic quantity measuring devices 101 attached to the circumferential surface of the rotating shaft to enable measurement at all times. This embodiment offers an advantage that there is no area where strain measurements cannot be taken ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com