Chewing gum possessing tooth cleaning effect and a teeth cleaning method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

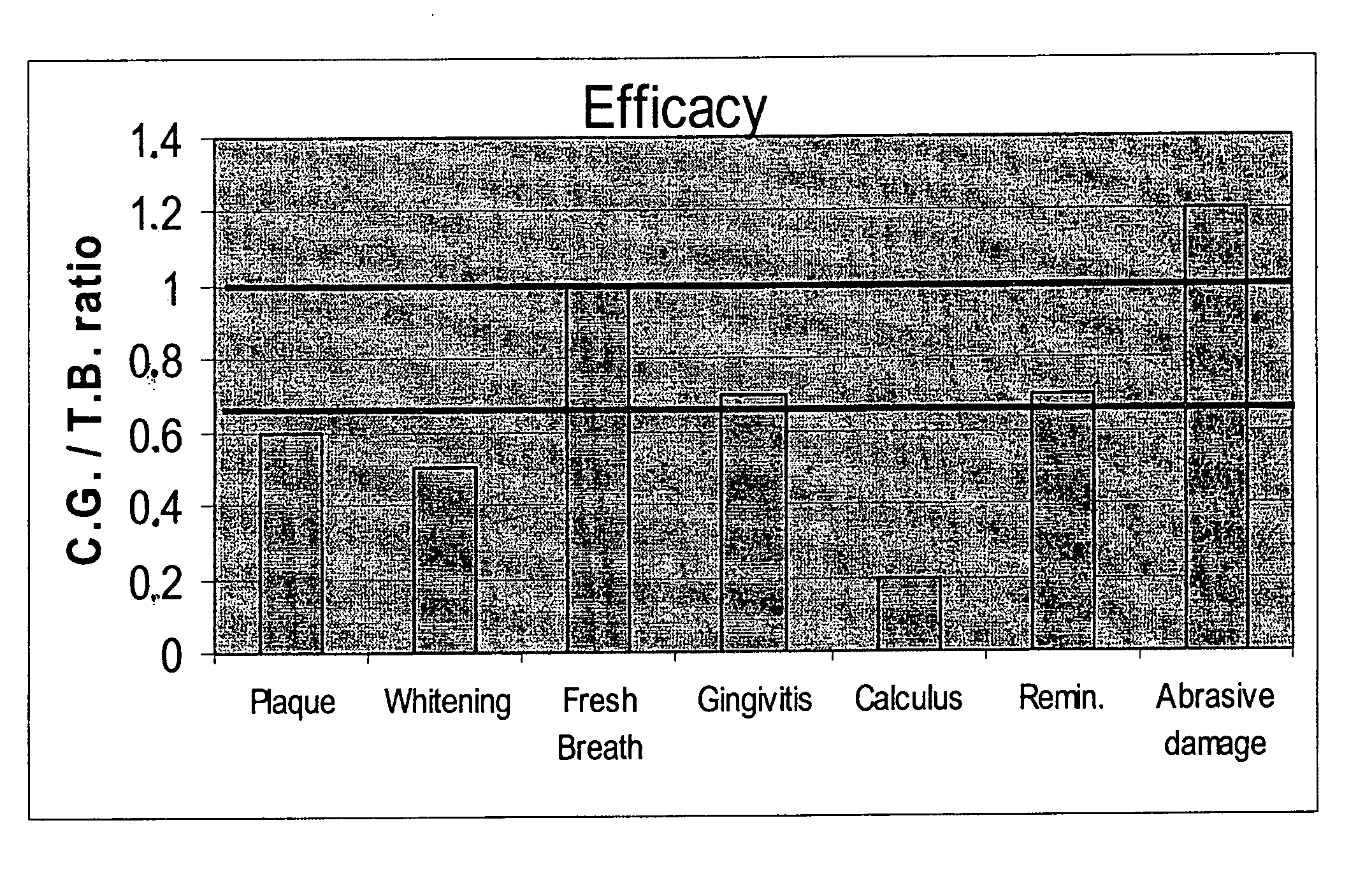

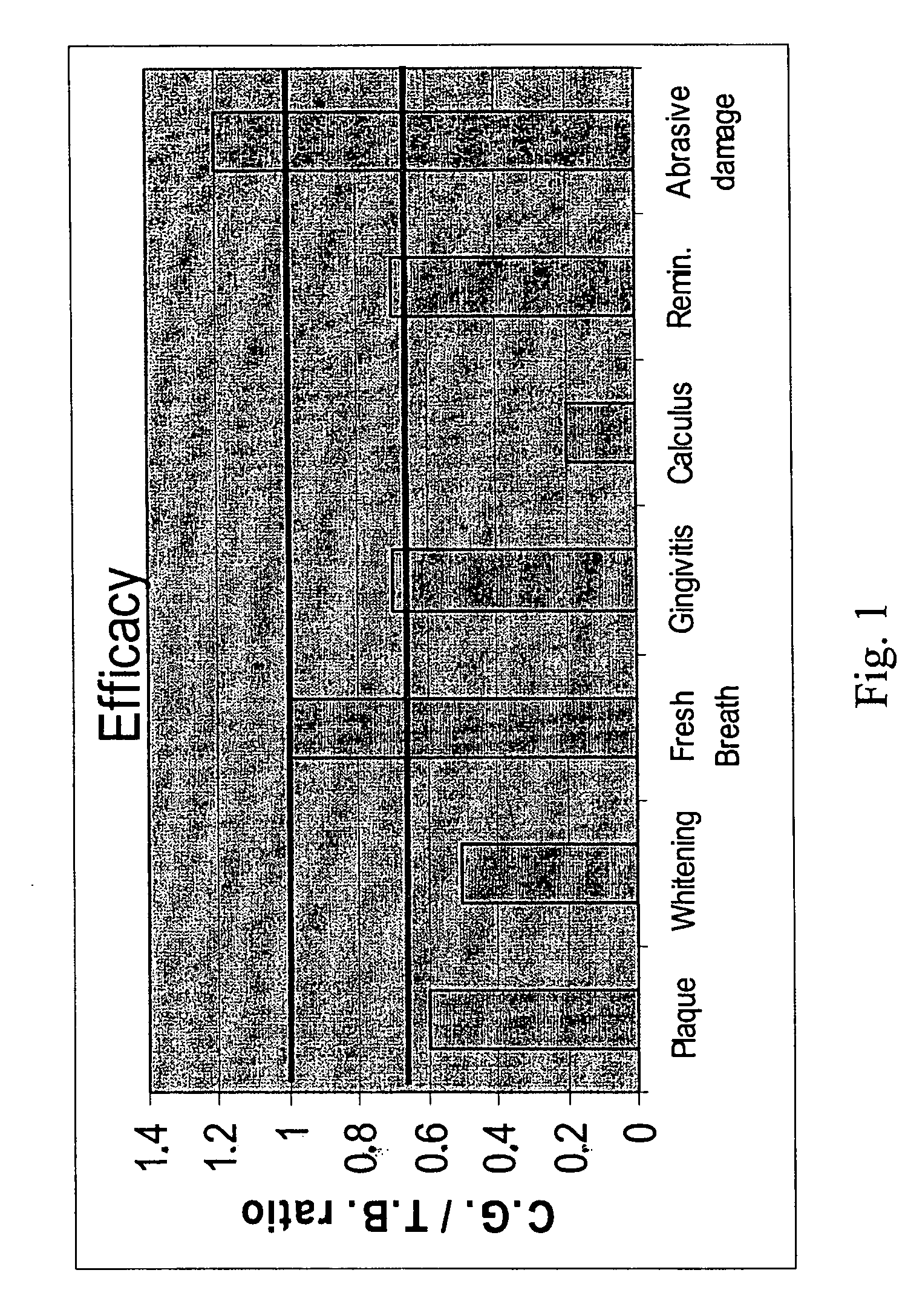

Image

Examples

example 1

[0167] The chewing gum in the following example was manufactured from commercially available gum base (Danfree, available from Gumlink A / S, Vejle, Denmark) mixed with sweeteners, taste ingredients and active ingredients. The chewing gum was manufactured as a two-layer product and the gum material for the two layers was produced with the following ratios:

[0168] Formulation 1:

Gum base60.00%Sorbitol18.20%Peppermint powder1.50%Menthol powder0.30%Dicalciumphosphate2.70%Green tea5.00%Baking soda0.40%Calcium carbonate4.10%Calcium pyrophosphate6.50%Succralose0.25%Magnesium stearate0.50%Eucalyptus powder0.50%

[0169] Formulation 2:

Gum base30.00%Xylitol68.80%Peppermint powder0.50%Menthole powder0.20%Magnesium stearate0.50%

[0170] The gum base was granulated (GALA underwater pelletizer) to form granules with diameters in the range of approximately 0.5-1.5 mm and mixed with the active ingredients.

[0171] The particulate mixture of formulation 1 (1.5 g) was filled into a tablet pressing machin...

example 2

Study for Assessing Oral Malodor

[0187] The purpose of this study was to demonstrate the efficacy of chewing gum containing green tea extract and zinc in reducing oral malodor (OM) as compared to a placebo.

Methods & Materials:

[0188] The investigation was a longitudinal study, which determined efficacy of the chewing gum in reducing oral malodor. A total of 20 subjects with self proclaimed oral malodor (OM) that has been verified by an organoleptic judge (OJ) were selected for this randomized clinical trial. Subjects were instructed to chew the provided gum five times a day for 20 minutes each time for a period of seven days.

[0189] Qualified subjects completed a demographic and a medical history survey and were assessed for degrees of OM. The qualifying score of the subjects as determined by self-proclamation and OJs was minimum of 2 or above on the 5-point malodor scale. Baseline (day 0) and post treatment (day 7) examinations included: 1) organoleptic tests 2) oral soft tissue ...

example 3

Study for Assessing Re-mineralization

Materials and Methods:

Demineralization Solution Preparation:

[0206] The demineralizing buffer solutions was made up of analytical-grade chemicals and deionized water. It contained 2.2 mM CaCl2, 2.2 mM NaH2PO4, 0.05 M acetic acid and pH was adjusted with 1 M KOH to 4.4.

Artificial Enamel Carious Lesion Formation:

[0207] Sound extracted molars were cleaned of any soft tissue debris and inspected for cracks, hypoplasia, and white spot lesions under the stereomicroscope. The teeth were then coated with acid-resistant varnish (Lancester, Germany), leaving a narrow ‘window’, approximately 1 mm wide, on the sound, intact surface of the buccal and / or lingual enamel. Each tooth was immersed, for 96 hours, in 10 ml of demineralizing solution in order to produce lesions of about 130-180 μm deep. The teeth were sectioned longitudinally through the lesions, approximately 100-150 μm thick, by a hard tissue microtome (Leica 1600, Wetzlar, Germany). Seventy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com