Segregated catalyzed metallic wire filter for diesel soot filtration

a technology of metallic wire filter and diesel engine, which is applied in the direction of engines, machines/engines, mechanical equipment, etc., can solve the problems of hardly ever reaching the 510° c. temperature level required to incinerate trapped particulates, affecting the regeneration of filters, and reducing engine efficiency. , to achieve the effect of reducing back pressure and favorable regeneration of filters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of a Catalyst Composition Containing Platinum and Palladium in a 4:1 Ratio

[0039] First platinum and palladium compounds were dispersed on high surface area gamma alumina and 5% lanthanum modified alumina supports. Into 2104.5 g of gamma alumina (97% solids) and 2041 g of 5% lanthanum stabilized alumina was added an aqueous solution containing 133.9 g of Pt as a 16% amine solubilized platinum hydroxide diluted with 709 g of deionized water with mixing. After mixing for additional 20 minutes a Pd solution was added containing 33.5 g Pd as a 19% palladium nitrate solution diluted with 700 g of deionized water. This was mixed an additional 20 minutes to ensure the powder was uniformly contacted with the precious metal solution.

[0040] The resulting precious metal support mixture from above was contacted with 6189 g of deionized water, 433.9 g of 90 acetic acid and 18 g of octanol in a dispersion tank. This mixture was fed into a continuous mill and ground until >90% of the ...

example 2

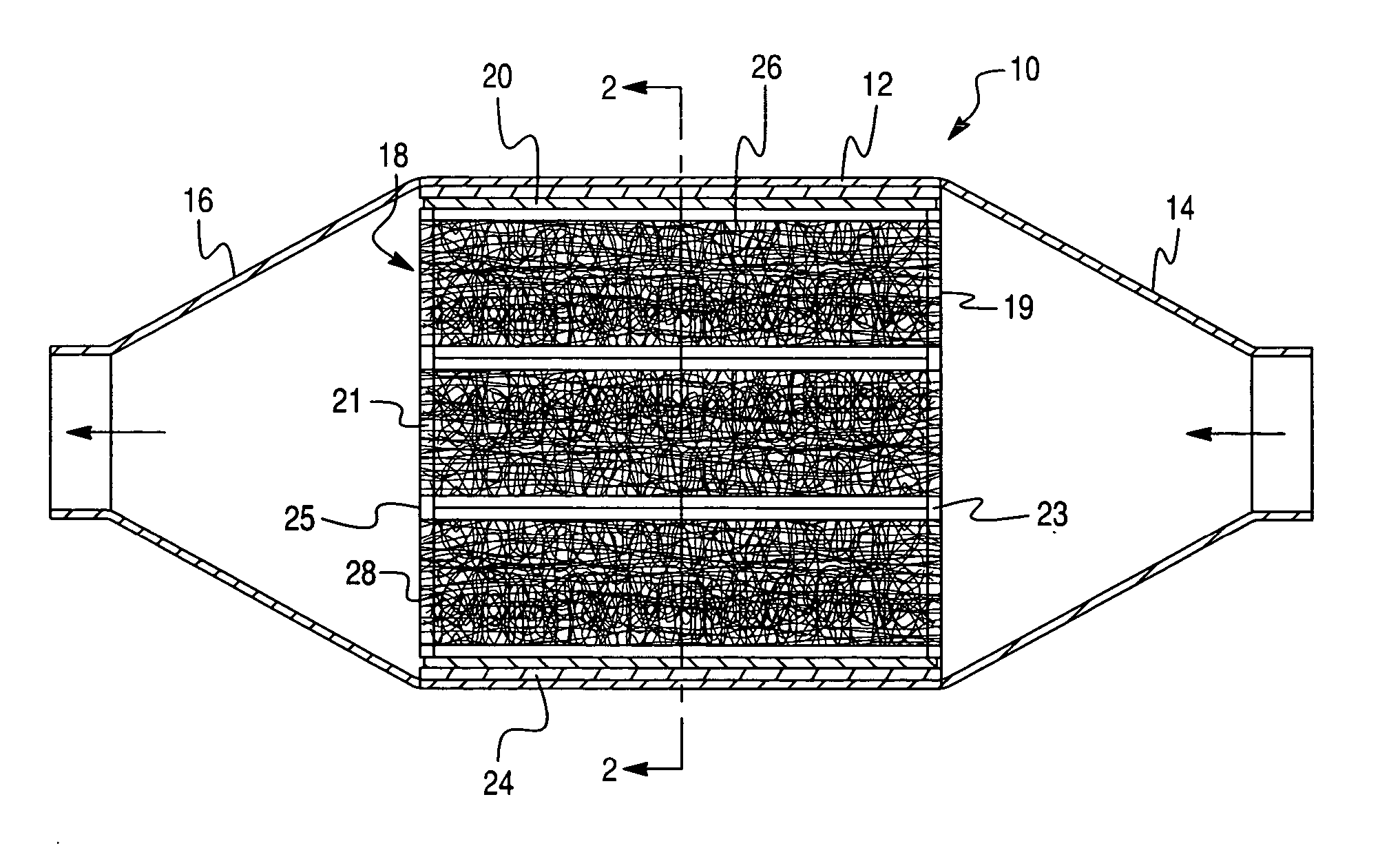

Preparation of Wire Mesh Foraminous Catalytic Substrate

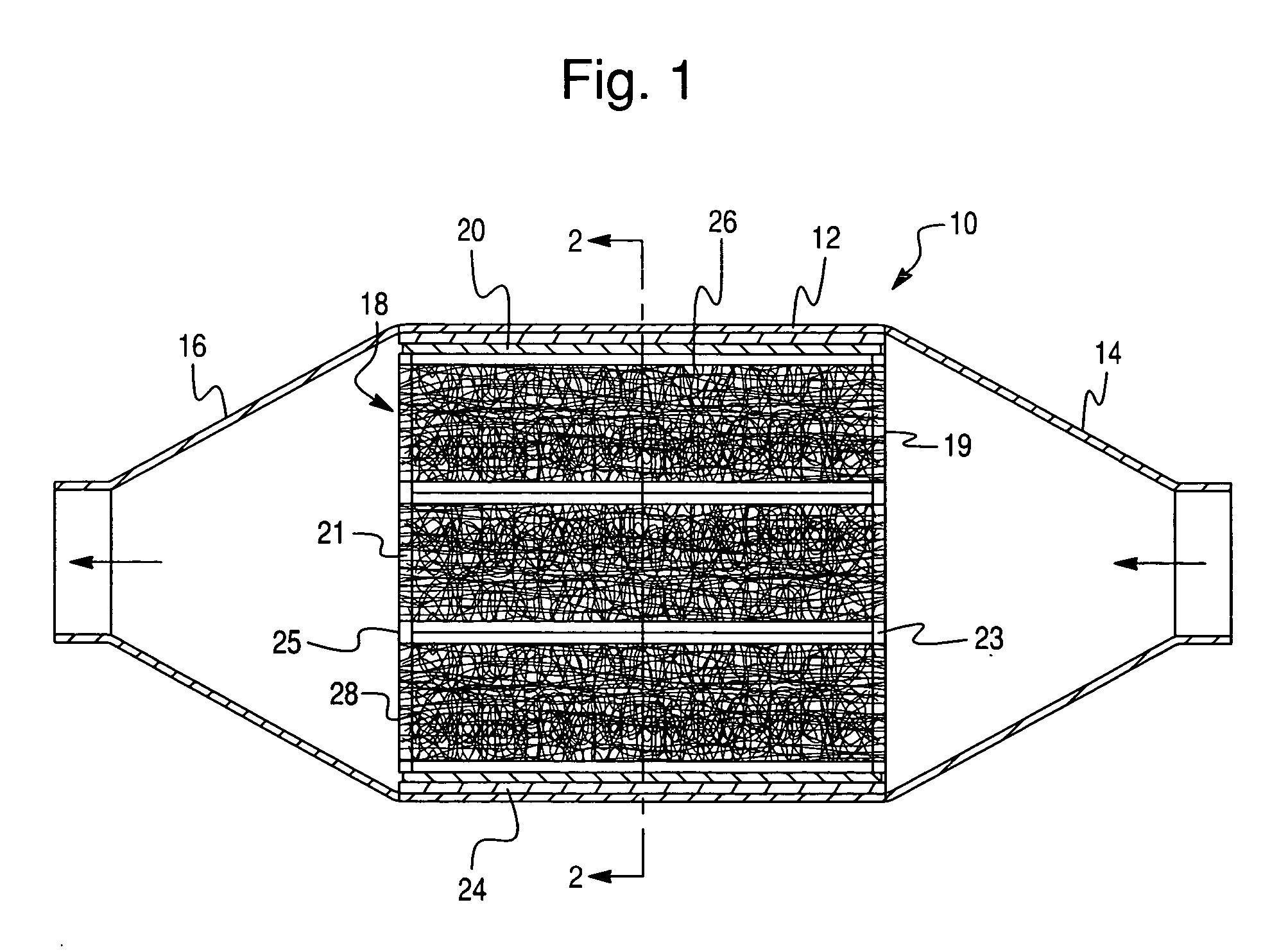

[0041] To prepare an article having the design as shown in FIG. 1, a stainless steel wool mesh was wire arc spray-coated with a nickel-aluminide alloy as described in Example 1 of the aforesaid '626 application. The steel wool mesh was then coated with the coating slurry described above (Example 1) at a washcoat loading of 0.05 to 0.1 g / in2. The mesh was then fitted into a cylindrical channel having an inside diameter of 1.25 in.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com