Phase shift mask blank, photo mask blank, and manufacturing apparatus and method of blanks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

.

[0078] Examples of the present invention will be described hereinafter in further detail.

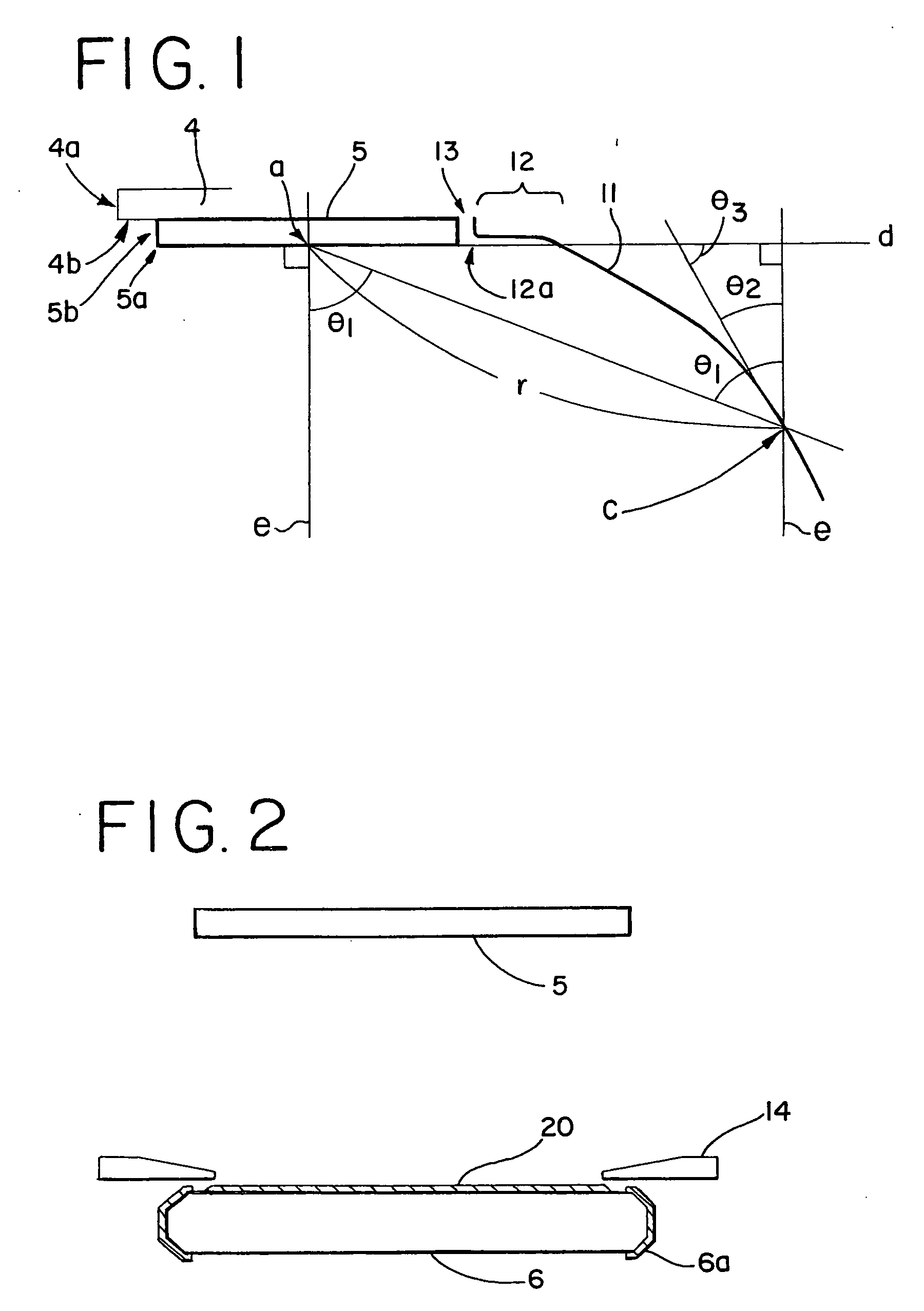

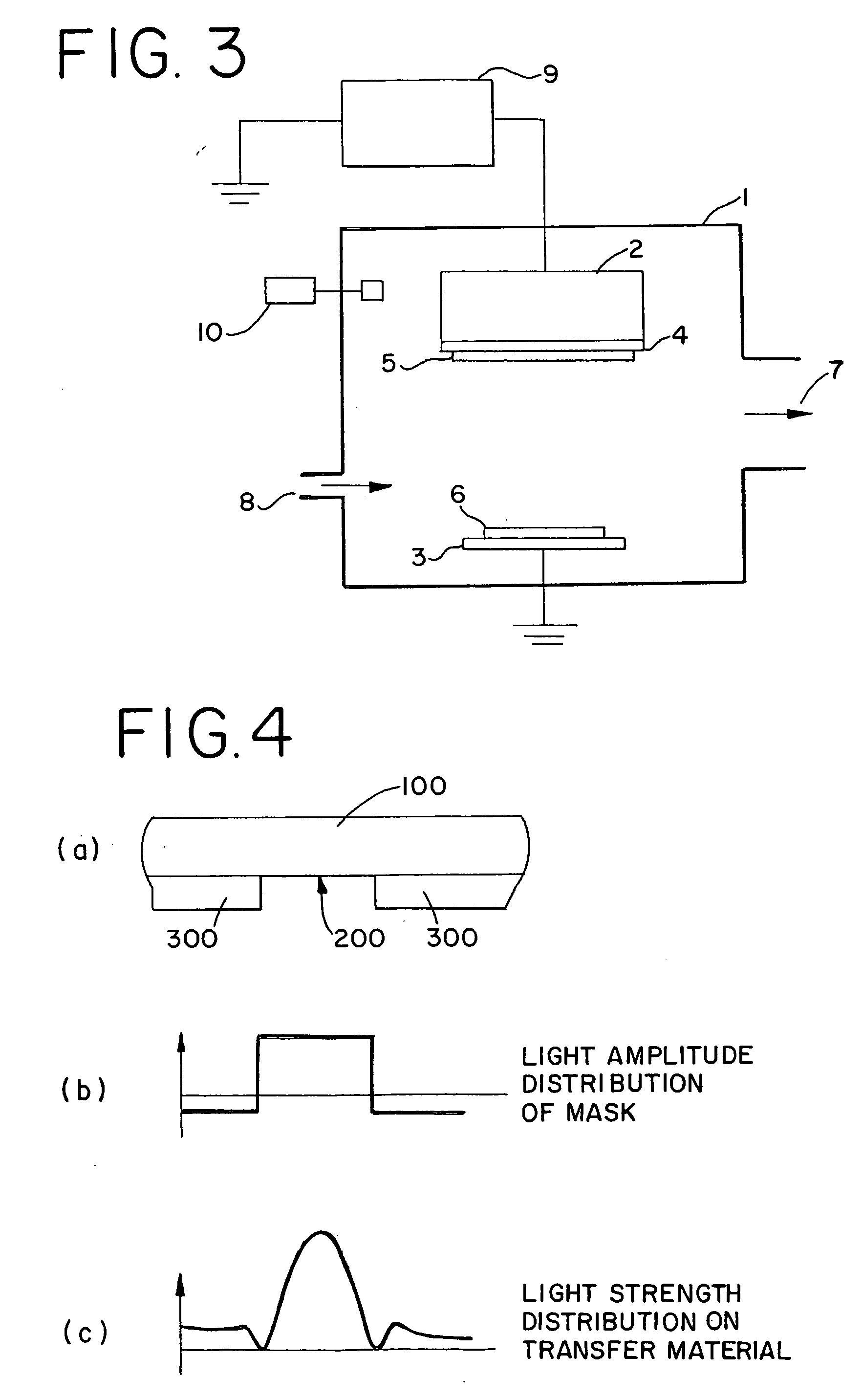

[0079] A DC magnetron sputtering apparatus shown in FIG. 3 was used, a combination of particle countermeasures shown in Table 1 is changed as shown in Table 2, and halftone phase shift mask blanks for ArF excimer laser (193 nm) were prepared.

[0080] Concretely, a mixed target (Mo:Si=8:92 mol %) of. molybdenum (Mo) and silicon (Si) was used to form a nitrided thin film (film thickness of about 670 angstroms) of molybdenum and silicon (MoSiN) on a transparent substrate by reactive sputtering (DC sputtering) in a mixed gas atmosphere (Ar:N2=10%:90%, pressure: 0.1 Pa) of argon (Ar) and nitrogen (N2). In this manner, the phase shift mask blank (film composition: Mo:Si:N=7:45:48) for ArF excimer laser (wavelength of 193 nm) was obtained.

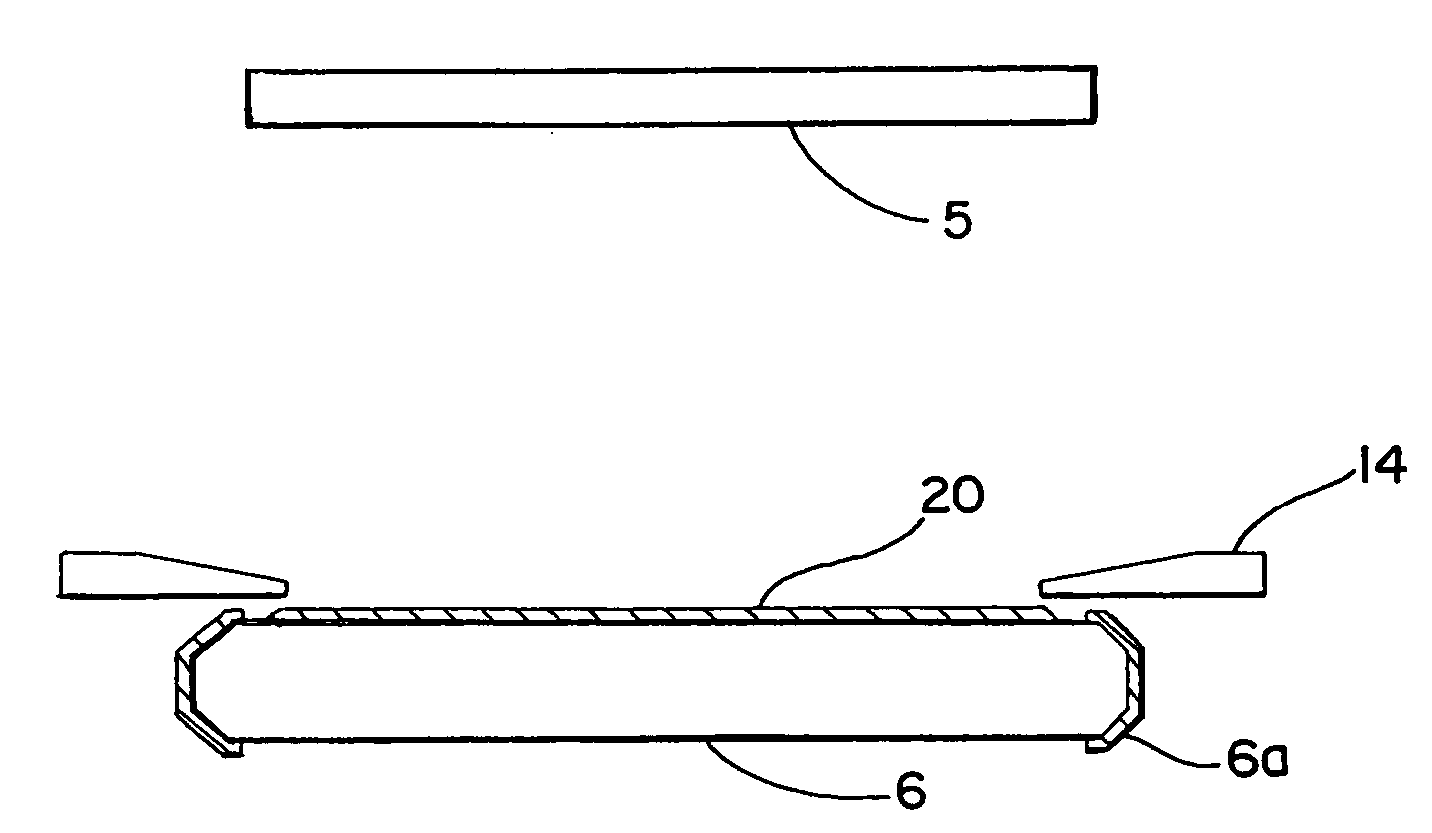

[0081] Here, the DC magnetron sputtering apparatus shown in FIG. 3 has a vacuum tank 1. A magnetron cathode 2 and substrate holder 3 are disposed in the vacuum tank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap