Method for low NOx combustion of syngas/high hydrogen fuels

a high hydrogen content, syngas technology, applied in the direction of combustion using lump and pulverulent fuel, combustion type, combustion using catalytic material, etc., can solve the problems of polluting the air, inefficiency of conventional coal-fired steam plants, and inefficient sources of electrical power, so as to reduce the effect of s

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

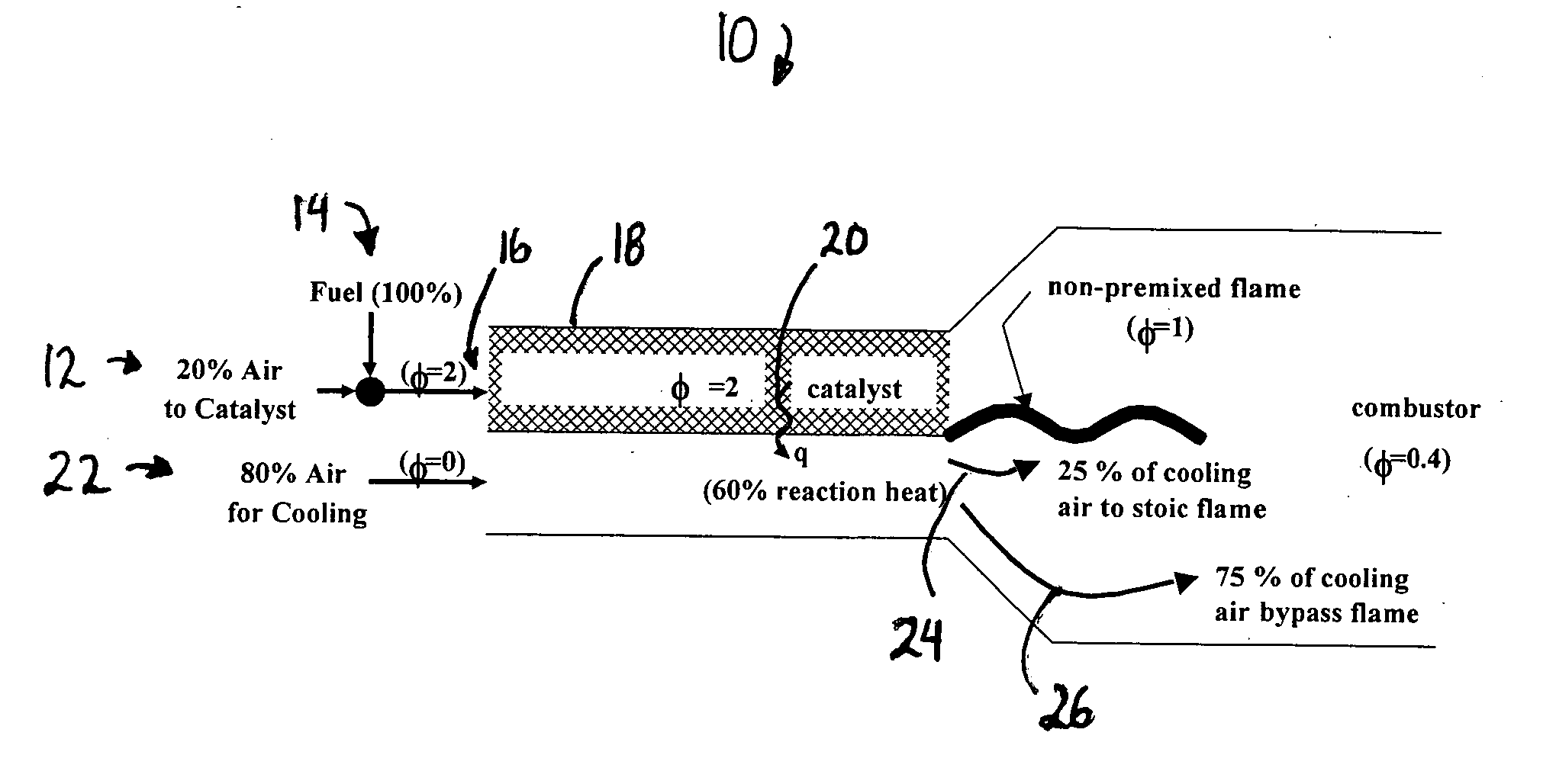

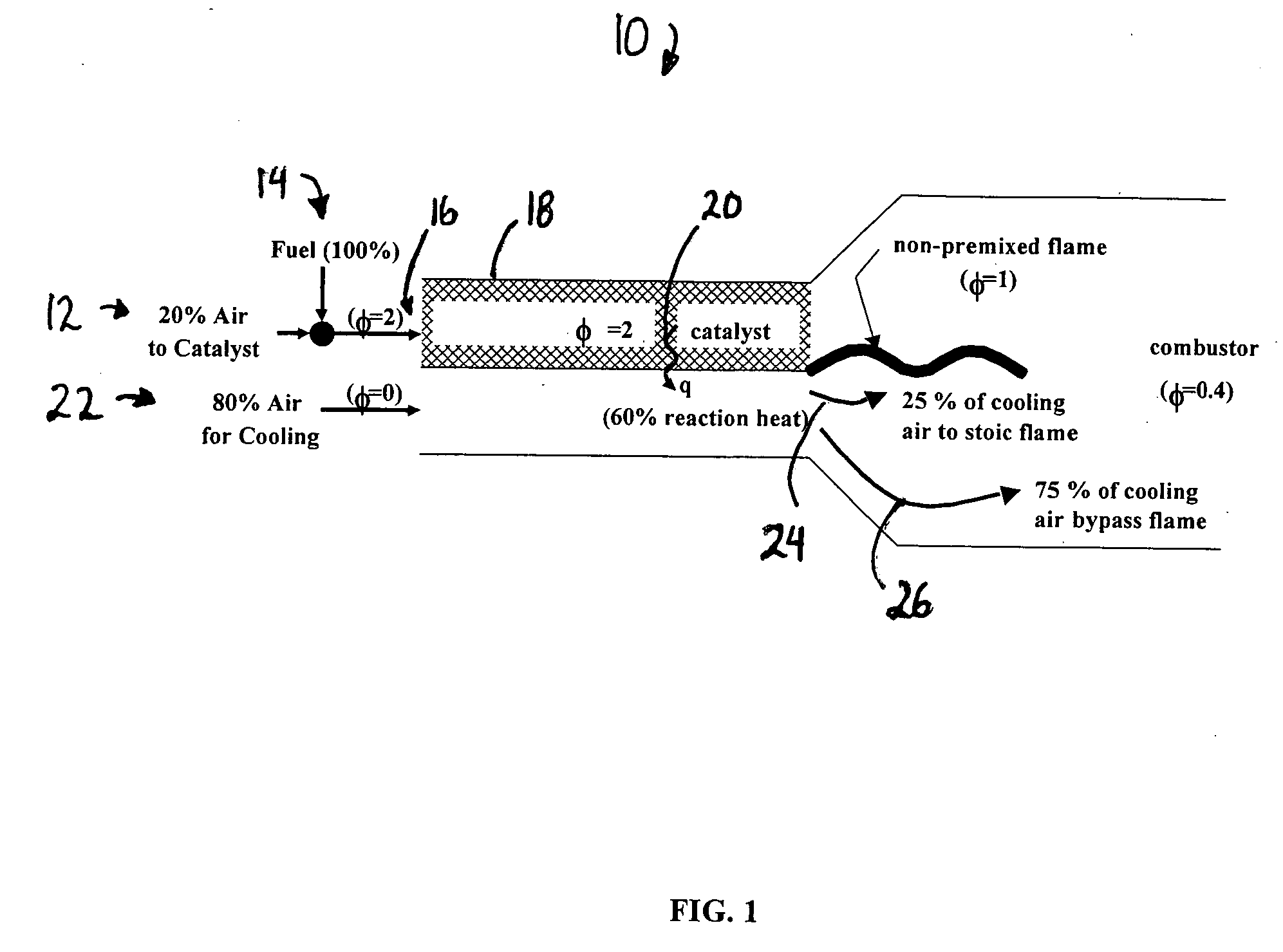

[0015] As shown for the example combustor 10 in FIG. 1, a twenty percent split of the combustion air 12 is mixed with the fuel 14 to form a fuel rich mixture 16 having an equivalence ratio of two, where a ratio of one is stoichiometric. Thus, a second twenty percent of the air is required to complete combustion. Complete conversion of the oxygen is assumed in a catalytic reactor 18 with sixty percent of the heat of combustion 20 (q) transferred to the balance of the combustion air 22. On contact of the reacted fuel with the remaining combustion air, only a second twenty percent of air 24 is required for stoichiometric combustion with the balance of the combustion air 22 bypassing the flame front. Thus, forty-five percent 26 of the reaction heat bypasses the flame zone reducing the heat liberated in the flame by about twenty percent.

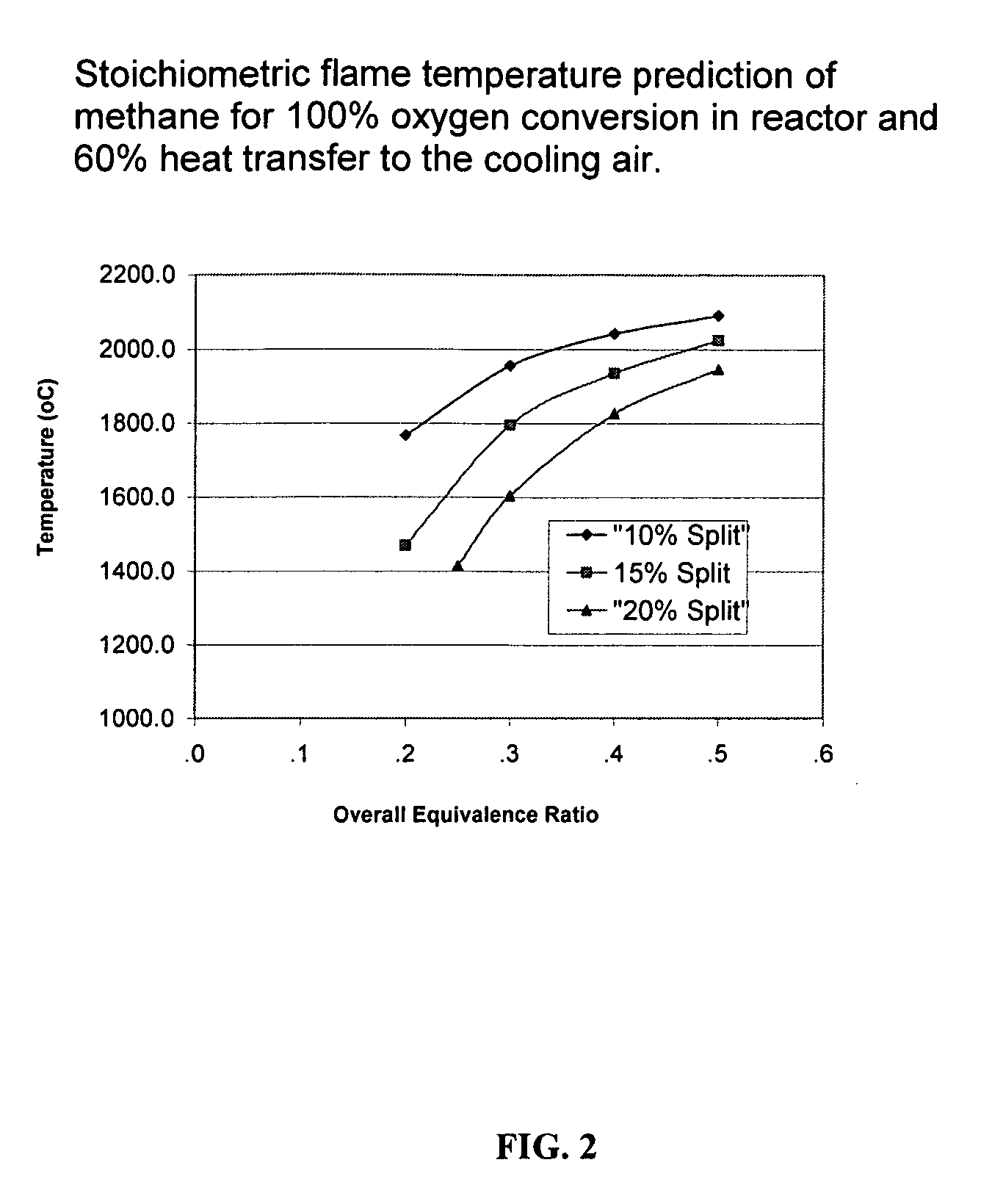

[0016] For conventional hydrocarbon fuels, including methane, the reduction in the heat liberated in the flame is not near enough for low NOx production...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com