Carbon foam thermal core

a technology of thermal core and carbon foam, which is applied in the field of carbon foam material, can solve the problems of noxious gases when burned, eps and other polymeric materials are flammable when exposed to heat, are subject to chemical degradation, etc., and achieve significant space and cost savings, non-flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

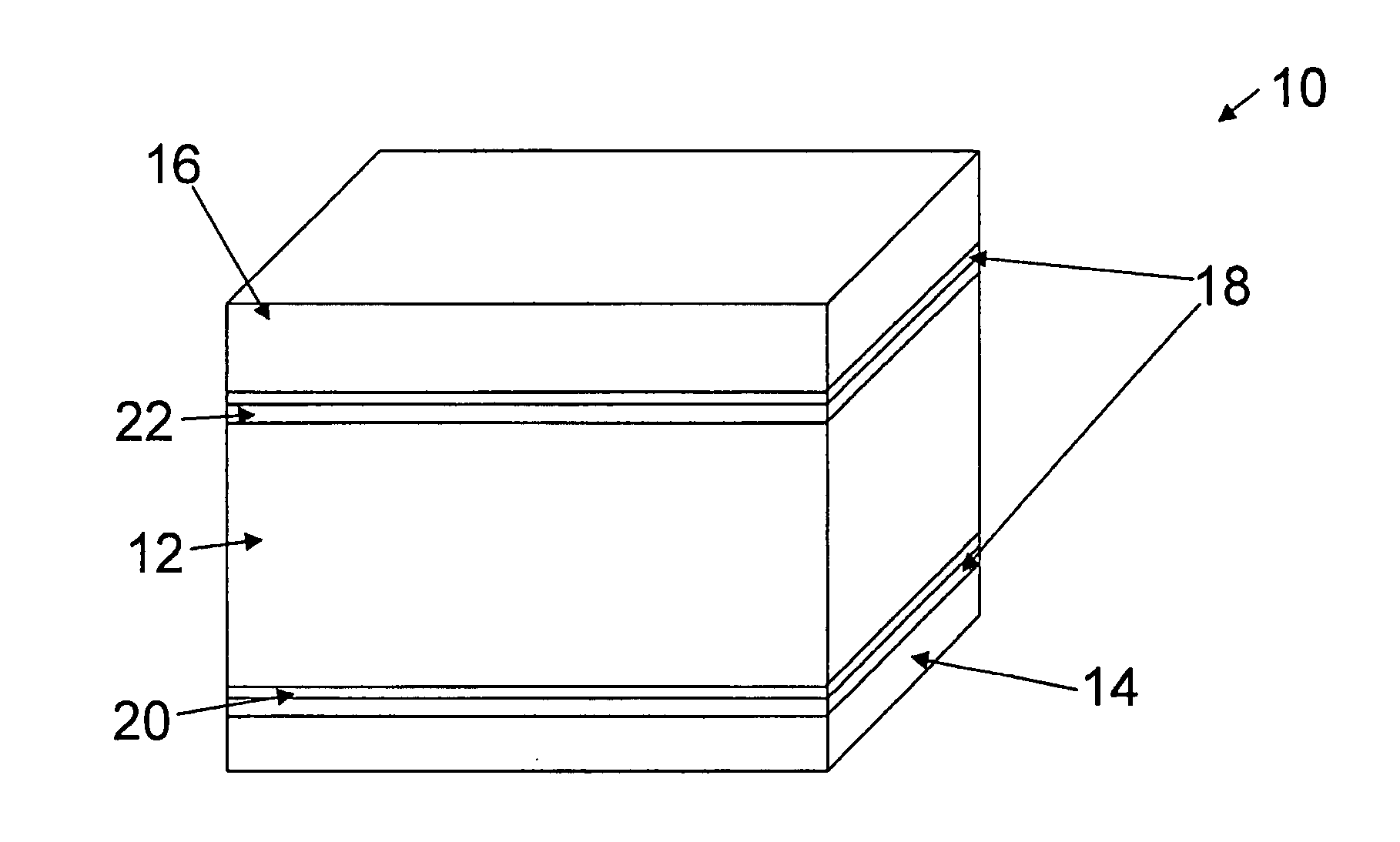

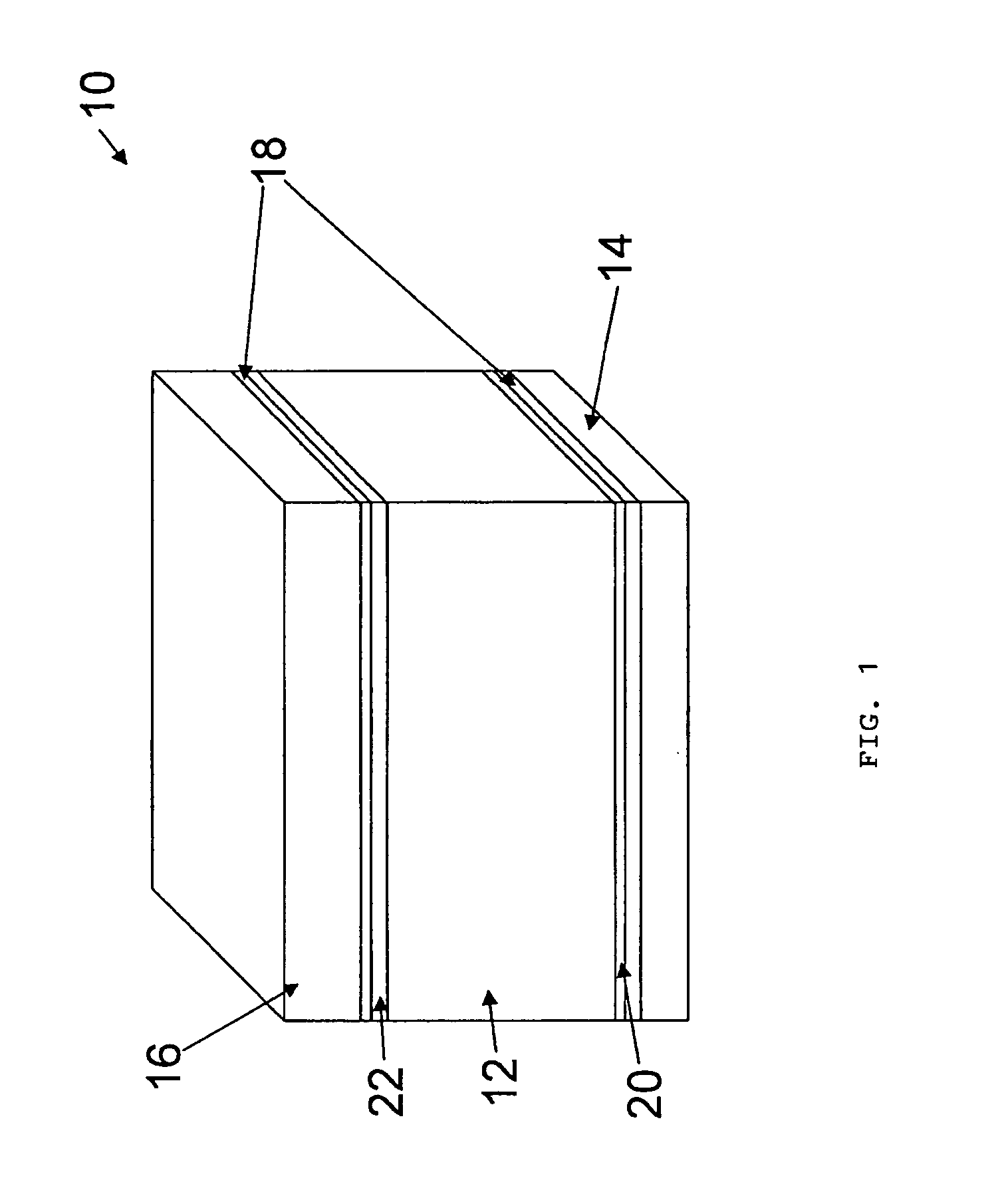

Image

Examples

Embodiment Construction

[0034] Carbon foams in accordance with the carbon foam core of the present invention are prepared from polymeric foams, such as polyurethane foams or phenolic foams, with phenolic foams being preferred. Phenolic resins are a large family of polymers and oligomers, composed of a wide variety of structures based on the reaction products of phenols with formaldehyde. Phenolic resins are prepared by the reaction of phenol or substituted phenol with an aldehyde, especially formaldehyde, in the presence of an acidic or basic catalyst. Phenolic resin foam is a cured system composed of open and closed cells. The resins are generally aqueous resoles catalyzed by sodium hydroxide at a formaldehyde:phenol ratio which can vary, but is preferably about 2:1. Free phenol and formaldehyde content should be low, although urea may be used as a formaldehyde scavenger.

[0035] The foam is prepared by adjusting the water content of the resin and adding a surfactant (eg, an ethoxylated nonionic), a blowin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com