Methods for treating dental conditions using tissue scaffolds

a tissue scaffold and treatment method technology, applied in the field of dental conditions, can solve the problems of failure to disclose the therapeutic method of the use of ex vivo cultured cells, failure to disclose the use of tissue scaffolds, and failure to describe the actual method of the use of such matrices in vivo, and achieve the effect of facilitating dentin regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

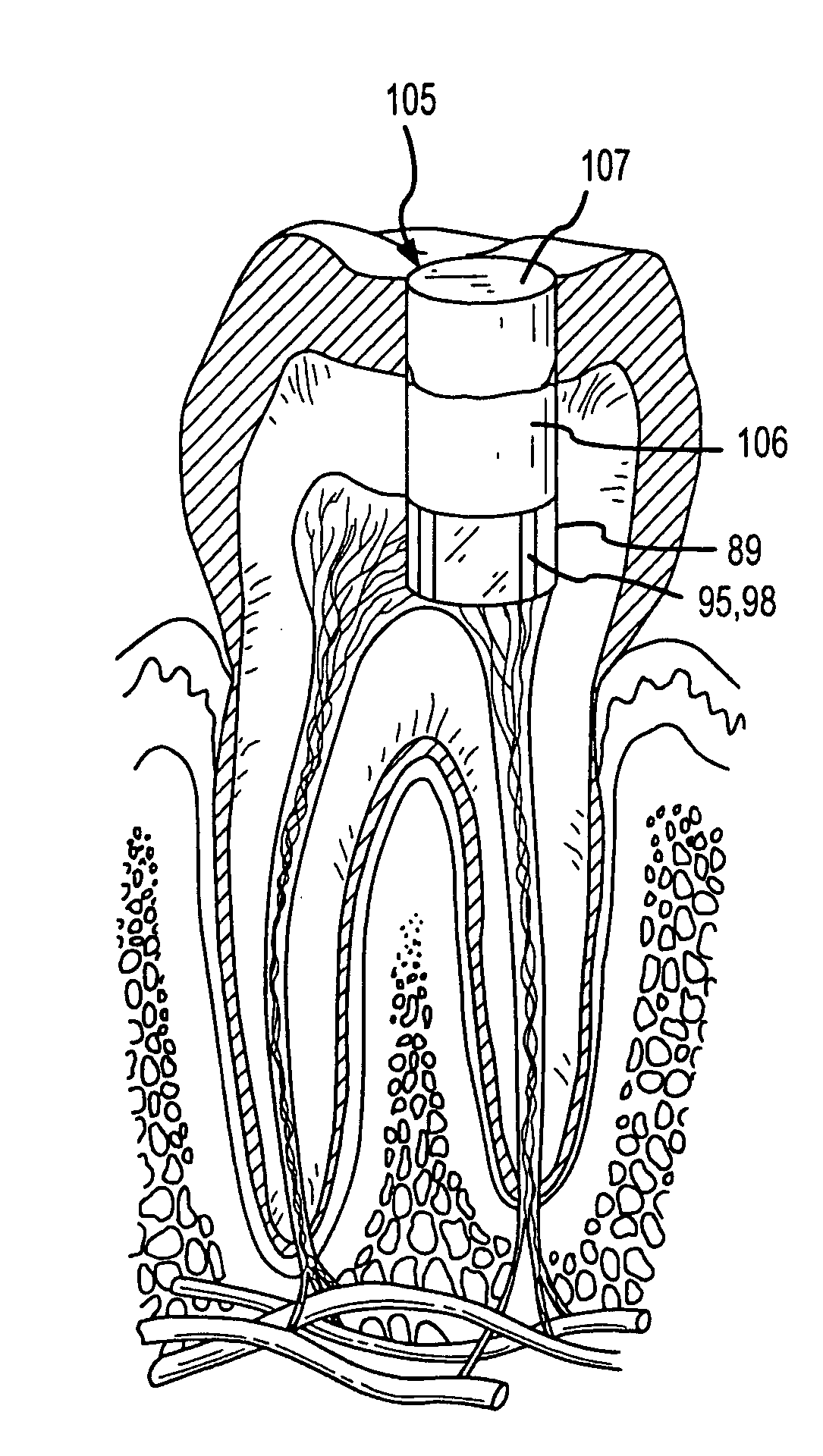

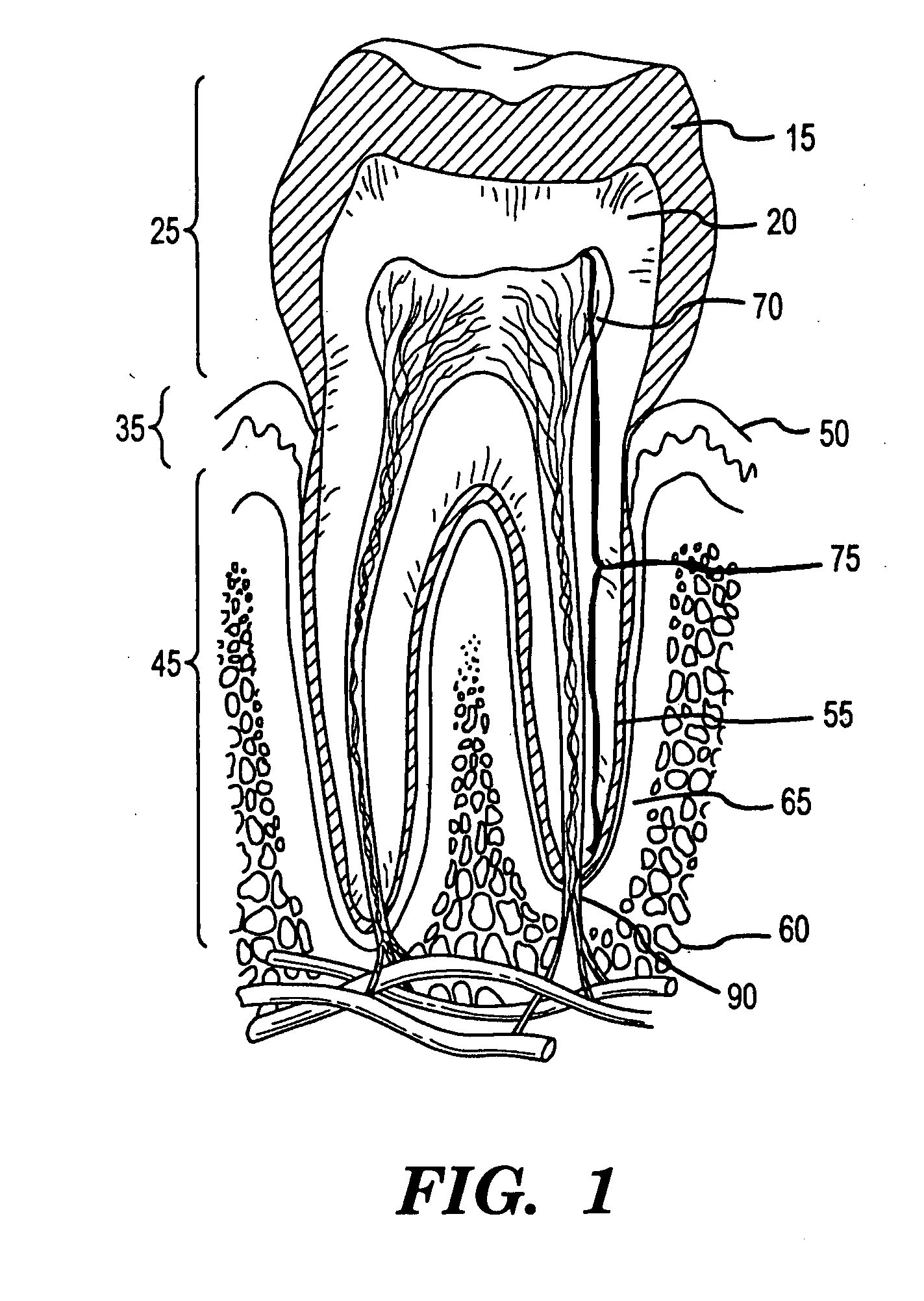

Image

Examples

example i

Fabricating Hollow Tube Tissue Scaffold Wafers of PLA, and PDLLA and PLGA

[0216] A. Materials

[0217] PLA, PDLLA, and the 85 / 15 and 50 / 50 PLGA were purchased from Medisorb (Cincinnati, Ohio), chloroform from Mallinckrodt (Paris, Ky.), polystyrene standards from Polysciences (Warrington, Pa.), aluminum backed tape from Cole-Parmer (Chicago, Ill.), phosphate buffered saline and DMEM medium from Gibco (Grand Island, N.Y.), Tmax film from Kodak, Lewis rats, 250 to 300 g, from Charles River (Wilmington, Mass.), and methoxyflurane from Pitman-Moore Inc. (Mundelein, III.).

[0218] Molecular weights of the various polymers were determined by gel permeation chromatography (Perkin-Elmer, Series 10, Newton Centre, Mass.), using polystyrene standards to generate a calibration curve. PLA had a molecular weight (Mw) of 74,000 (Mw / Mn=1.6); poly-(D,L lactic) acid had Mw=77,000 (Mw / Mn=1.8); 85 / 15 copolymer had Mw=69,000 (Mw / Mn=1.9); 50 / 50 copolymer Mw=43,400 (Mw / Mn=1.43). Differential scanning calorim...

example ii

Making PGA Tubular Tissue Scaffolds Stabilized by Spray Casting with PLLA and PLGA

[0234] Another method to stabilize PGA meshes, described in this example, is to atomize solutions of poly(L-lactic acid) (PLLA) and a 50 / 50 copolymer of poly(D,L-lactic-co-glycolic acid) (PLGA) dissolved in chloroform and to spray over meshes formed into hollow tubes. The PLLA and PLGA coated the PGA fibers and physically bonded adjacent fibers. The pattern and extent of bonding was controlled by the concentration of polymer in the atomized solution, and the total mass of polymer sprayed on the device. The compression resistance of devices increased with the extent of bonding, and PLLA bonded tubes resisted larger compressive forces than PLGA bonded tubes. Tubes bonded with PLLA degraded more slowly than devices bonded with PLGA.

[0235] PGA fiber meshes are stabilized by physically bonding adjacent fibres using a spray casting method. Poly L-lactic acid (PLLA) or a 50 / 50 copolymer of lactic and glycol...

example iii

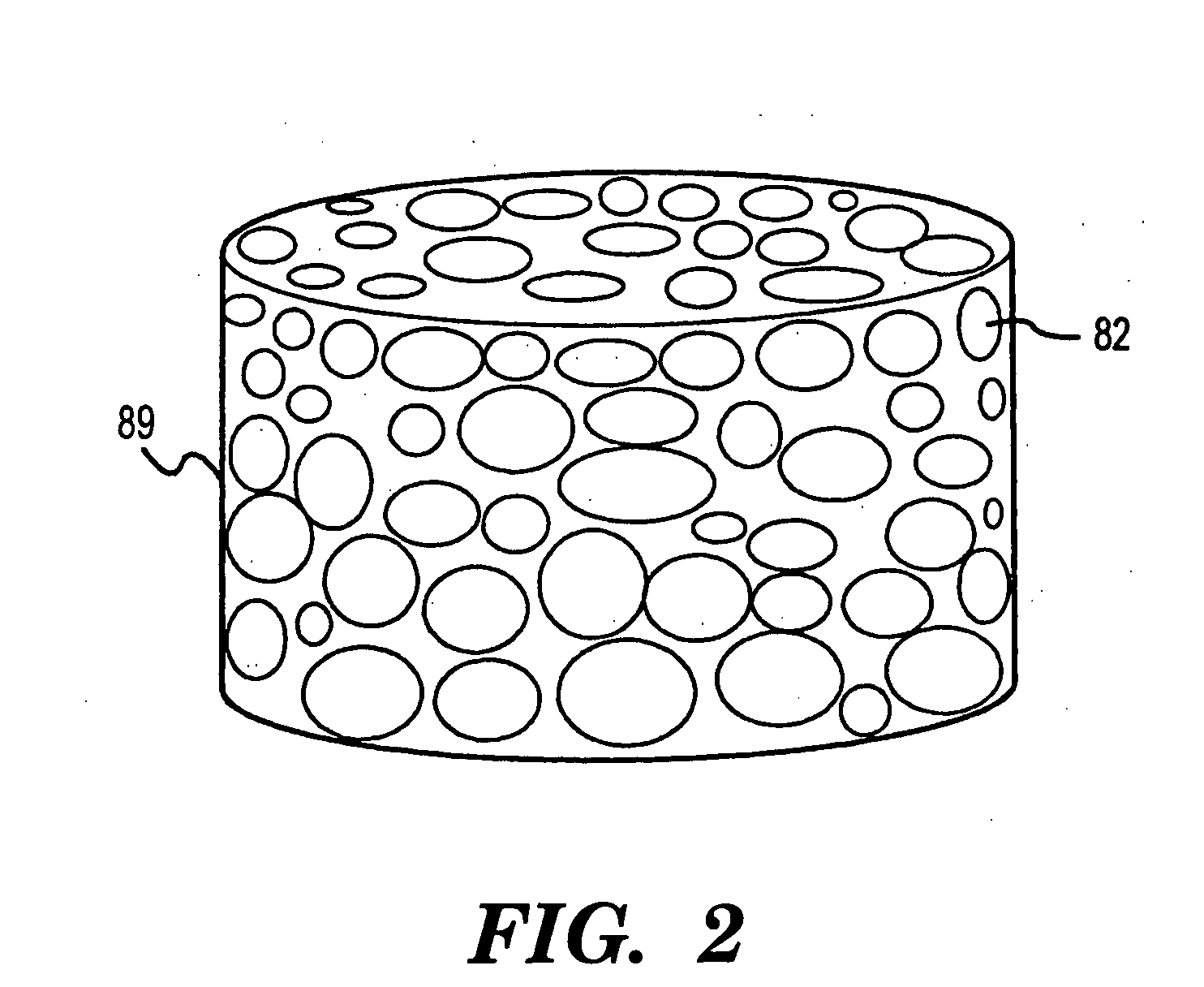

Making a PLGA Sponge Matrix Tissue Scaffold Wafer

[0254] Pellets of an 85:15 copolymer of D,L-lactide and glycolide (PLGA) was purchased from Boehringer Ingelheim (Henley, Montvale, N.J., USA), and utilized to fabricate polymer matrices in all experiments. The intrinsic viscosity of the polymer was about 1.3-1.7. Polymer pellets were ground using a Tekmar grinder (Bel-Art Products, Pequannock, N.J., USA), and sieved to obtain particles ranging from 106 to 250 pm. In certain experiments the polymer particles were mixed with sodium chloride particles (Mallinckrodt, Paris, Ky., USA). The salt particles were sieved to yield a range of sizes, and the weight ratio of NaCl:PLGA masses ranged from 0 to 50. In all cases, the total mass of PLGA and NaCl was held constant at 0.8 g. The mixtures of PLGA and NaCl were loaded into a KBr die (1.35 cm in diameter; Aldrich Chemical Co., Milwaukee, Wis., USA), and compressed at 1500 psi for 1 minute using a Carver Laboratory Press (Fred S. Carver, In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com