Integrated circuit wafer packaging system and method

a technology of integrated circuit and packaging system, which is applied in the direction of packaging goods, furnaces, containers preventing decay, etc., can solve the problems of ic wafers not having the necessary features, scratching during the wafer insertion and transport process, and present-day transport media designed for packaging ic wafers lacking the necessary features, etc., to eliminate or seriously minimize the effect of corrosive amcs, eliminating or seriously minimizing the force caused by handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The invention is a system hereinafter referred to the Critical Packaging System or CP System consisting of a box / container in combination with multiple means and methods including an apparatus.

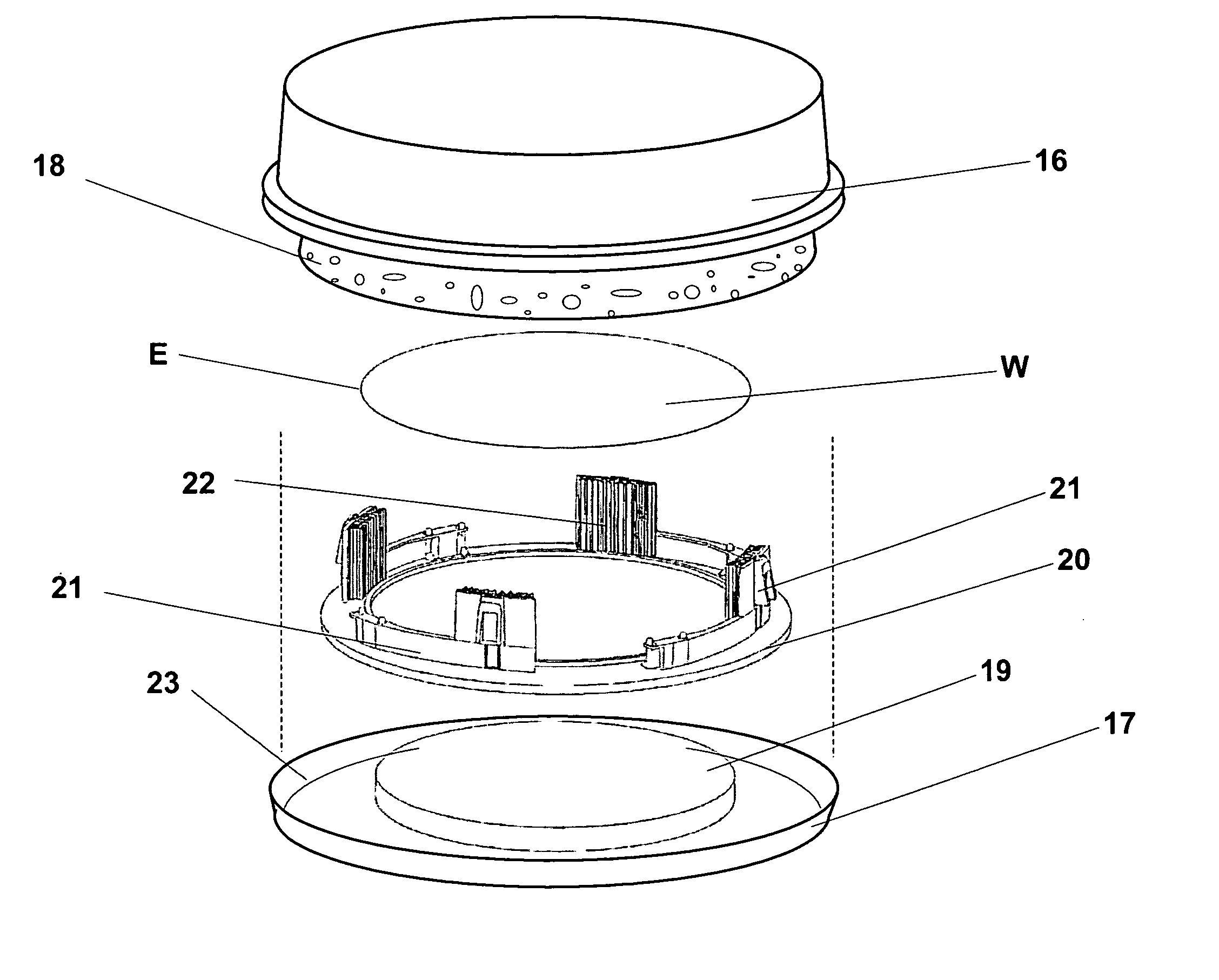

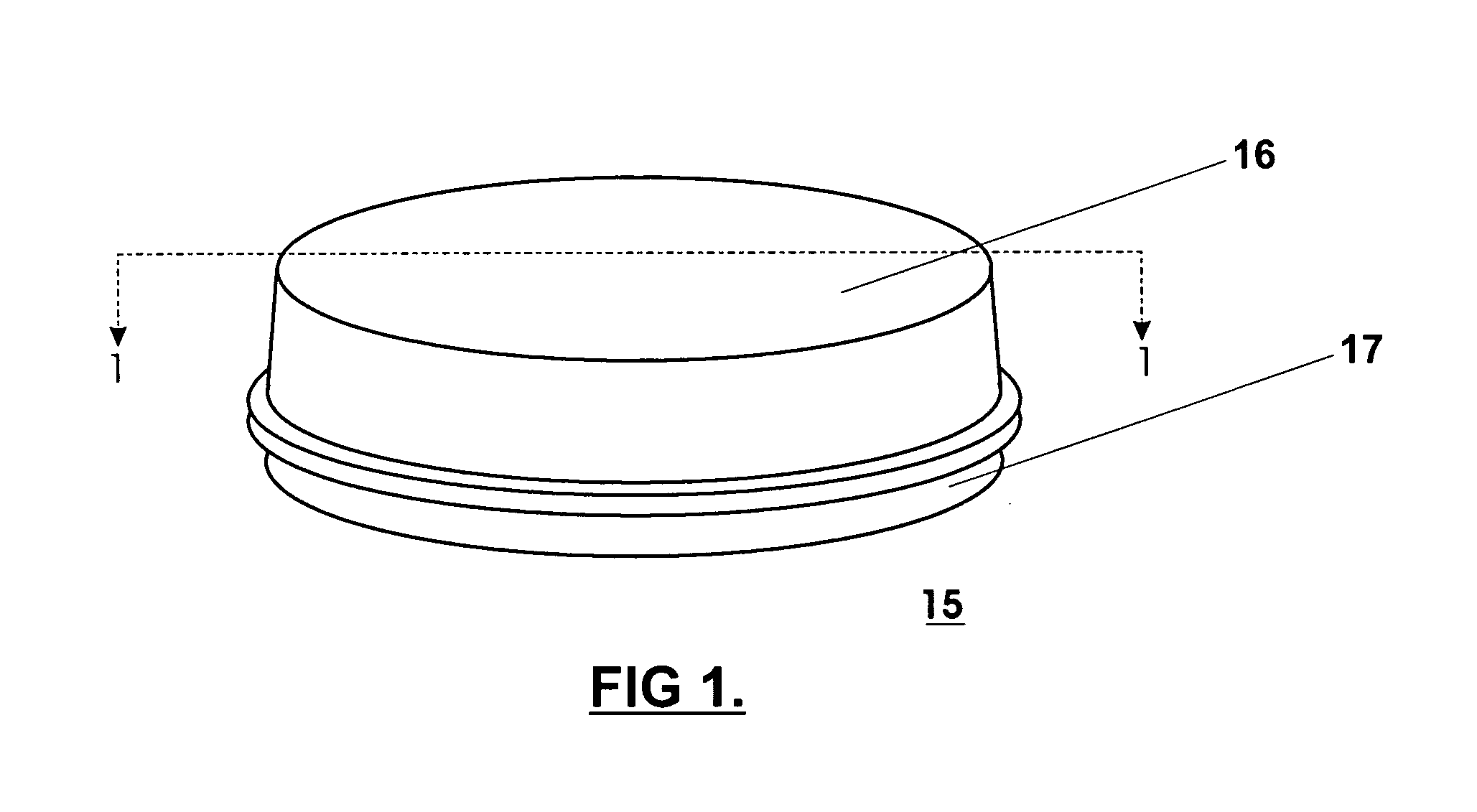

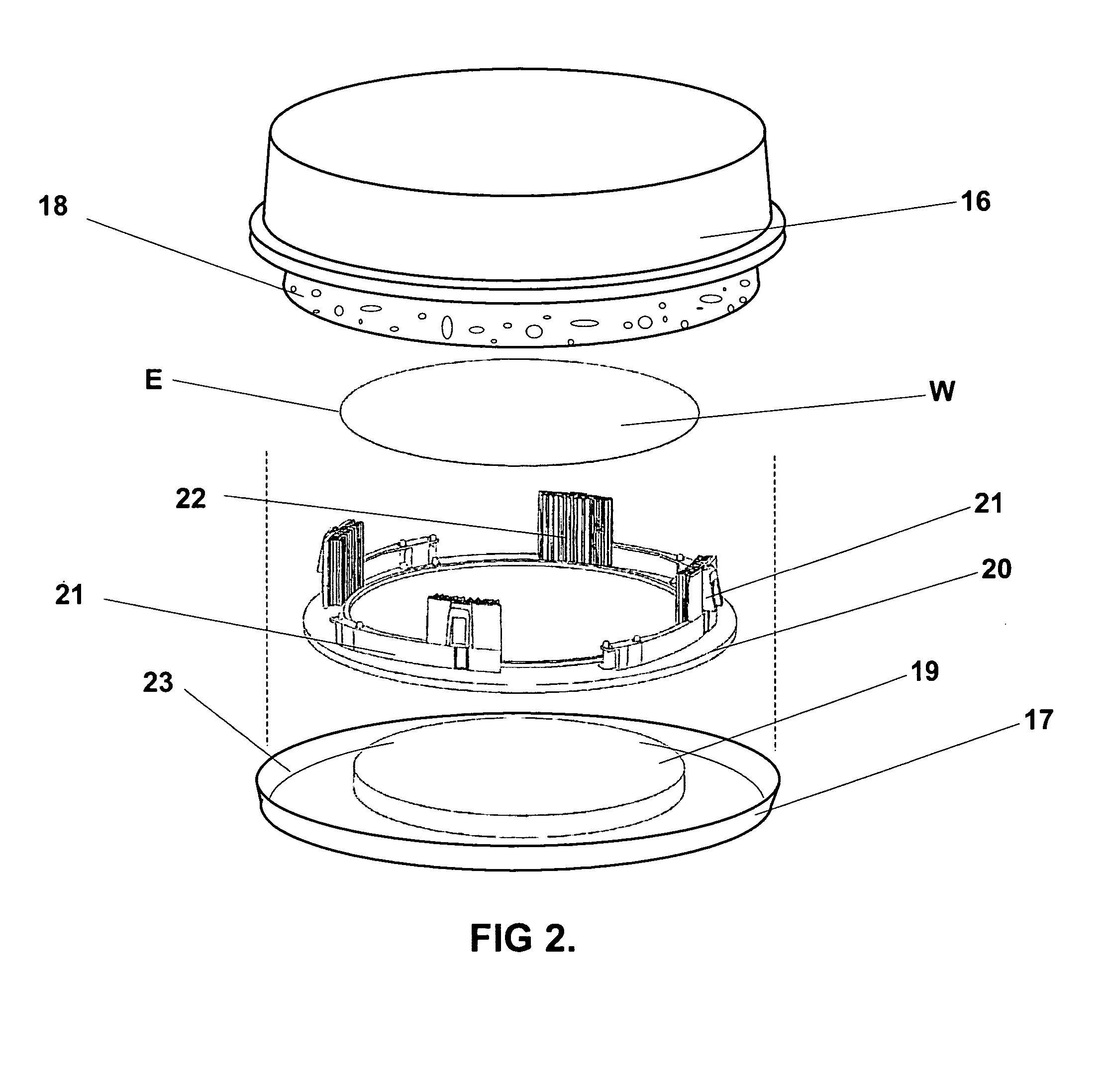

[0081] A first arrangement of the embodiment of the invention as illustrated in FIGS. 1, 2, 3, and 4. The box or container is referred to as WEC (Wafer Environmental Control) Smart Box that is designed to comply with all the features of the CP System. The box / container is molded of a synthetic resinous material such as ABS and is designed in a manner to accommodate and resolve critical issues such as contaminating Airborne Molecular Contaminants, directional forces during shipment phases that create motion for packaged wafers that cause surface damage and means to absorb shock energy caused by mishandling, all of which occur during shipment phase.

[0082]FIG. 1 is an isometric view of an embodiment of the invention. FIG. 1 shows a Box / container 15 with a top cover 16 and a bottom cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com