Method to limit a creep of bolts and gaskets of bolted flanged connections

a bolt and flange connection technology, applied in the direction of threaded fasteners, machines/engines, washing machines, etc., can solve the problems of gasket damage and failure, complex structural integrity of the bfcs and plant/piping operation leakage reduction, and cost each process industry hundreds of millions of dollars annually in lost profits. , to achieve the effect of maximizing the efficiency of critical technological equipment and increasing the bfc leak-tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

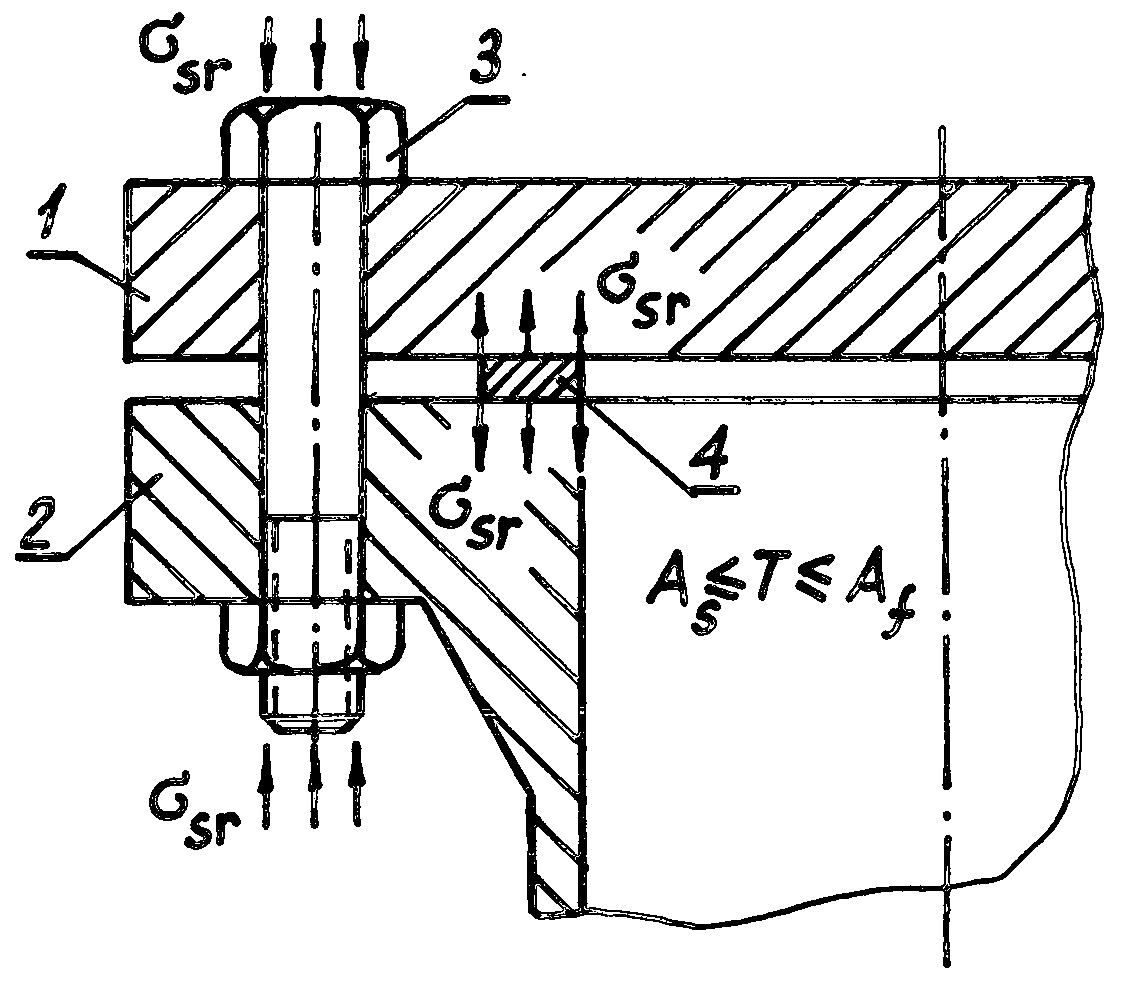

[0041]FIG. 1 is a cross-sectional view of a part of BFC having the flanges 1 and 2 of conventional structural steel, and bolts 3 and gasket 4 manufactured from the same SMA having temperature interval As≦T≦Af of reverse martensitic phase transformation that is close to operational temperatures of the BFC. Bolts and gasket are shape-memorized to the compression (bolts) and “swelling” (gasket). The constrained shape recovery of stretched bolts and compressed gasket at temperature interval As≦T≦Af produces reactive shape-recovering stresses σsr having direction inverse to the direction of operational creep of the bolts and gasket. Hence, FIG. 1 illustrates a main principle of “negative creep” effect that limits or excludes elongation of the bolts and contraction of the gasket due to their operational creep under temperature interval As≦T≦Af of the BFC.

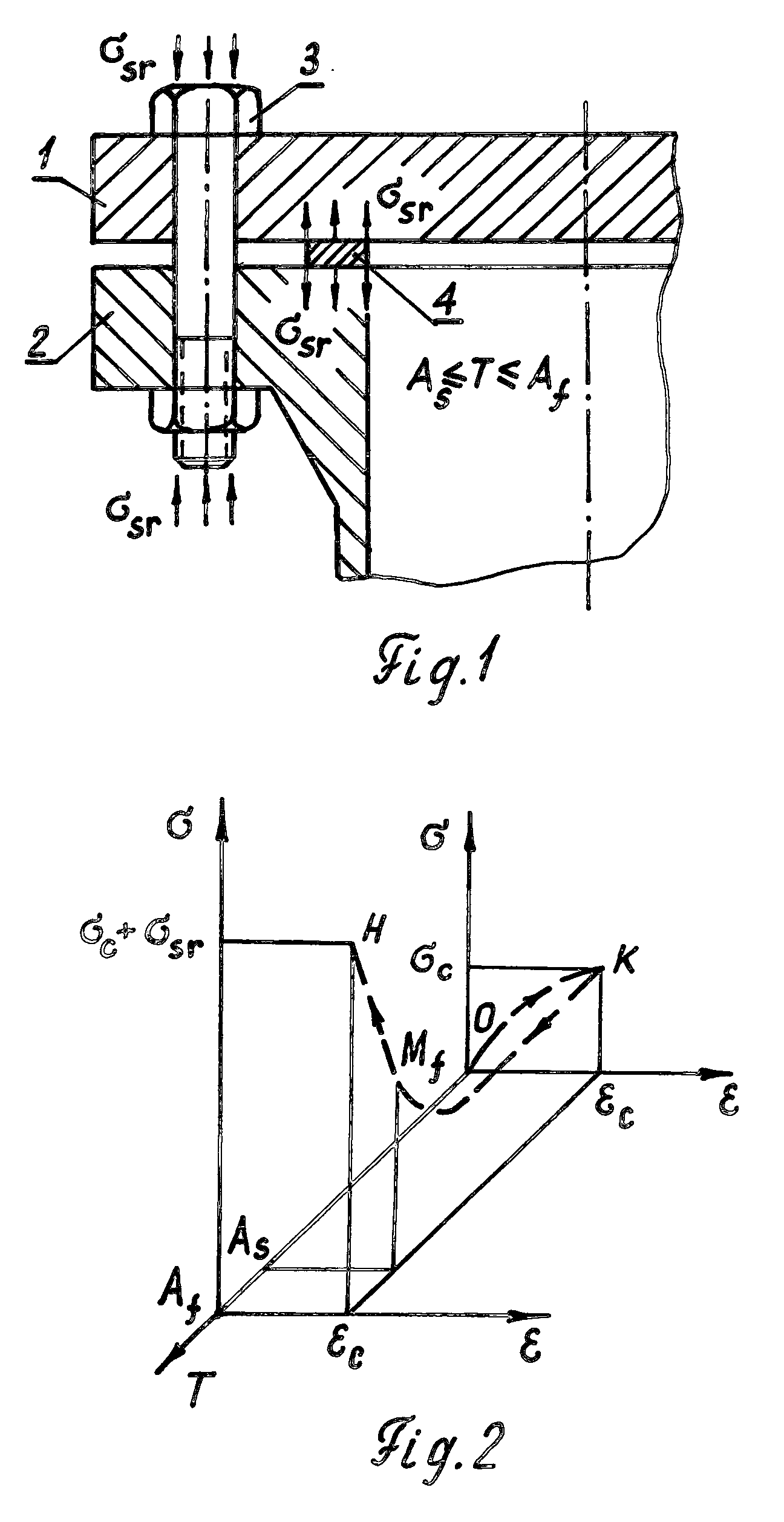

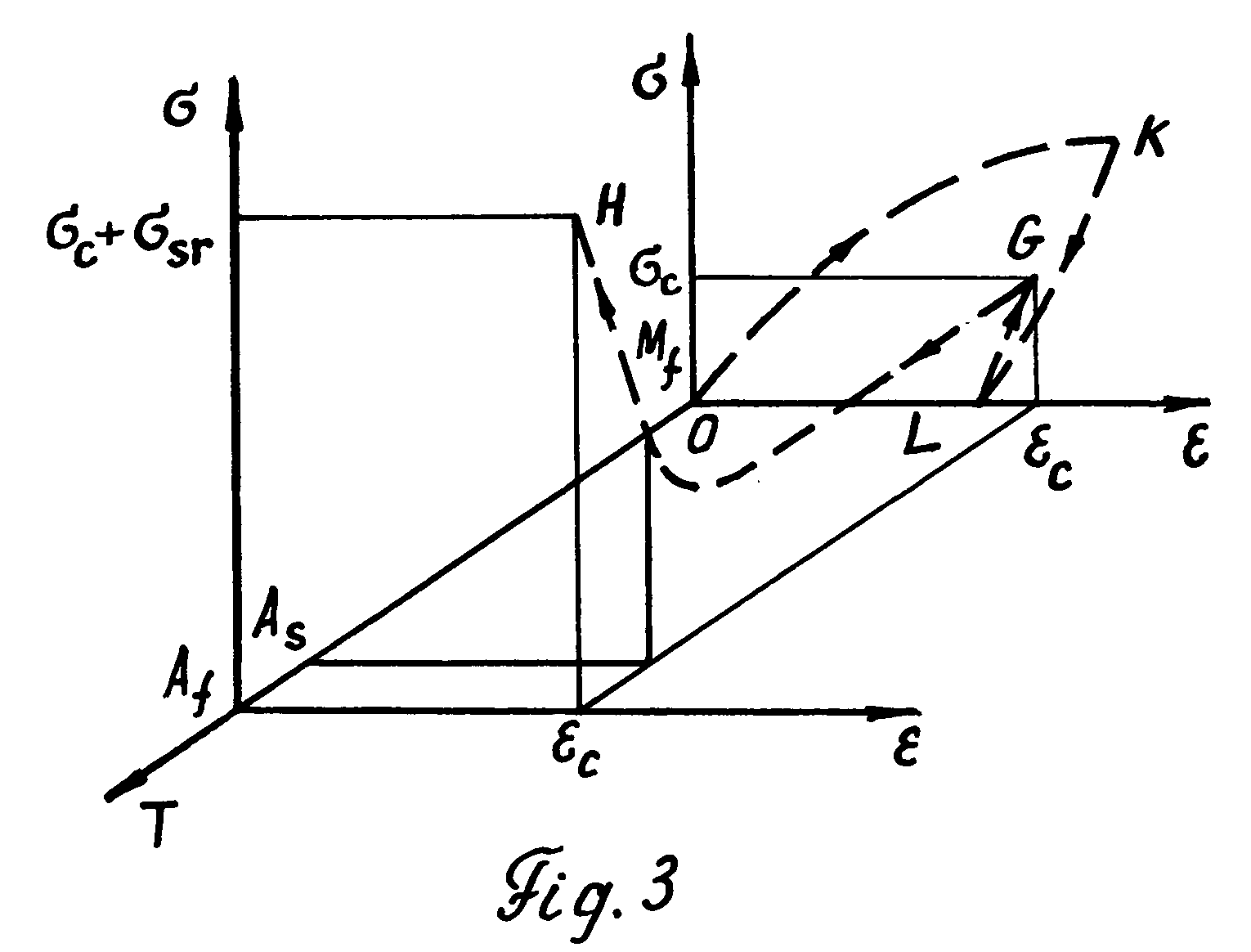

[0042]FIG. 2 is a schematic representation of constrained shape recovery of the bolt of SMA that is stretched by bolt preload force from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com