Polycrystalline Sic Electrical Devices and Methods for Fabricating the Same

a technology of polycrystalline sic and electrical devices, which is applied in the field of new electrical devices, can solve the problems of increasing the market potential of gas igniters, affecting the performance of gas igniters, and reducing the service life of standing pilot lights for many appliance types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

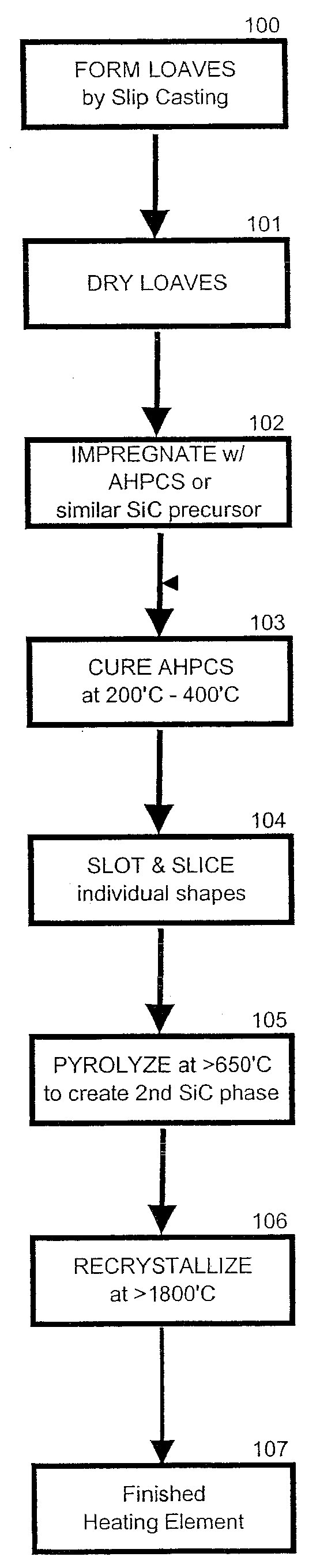

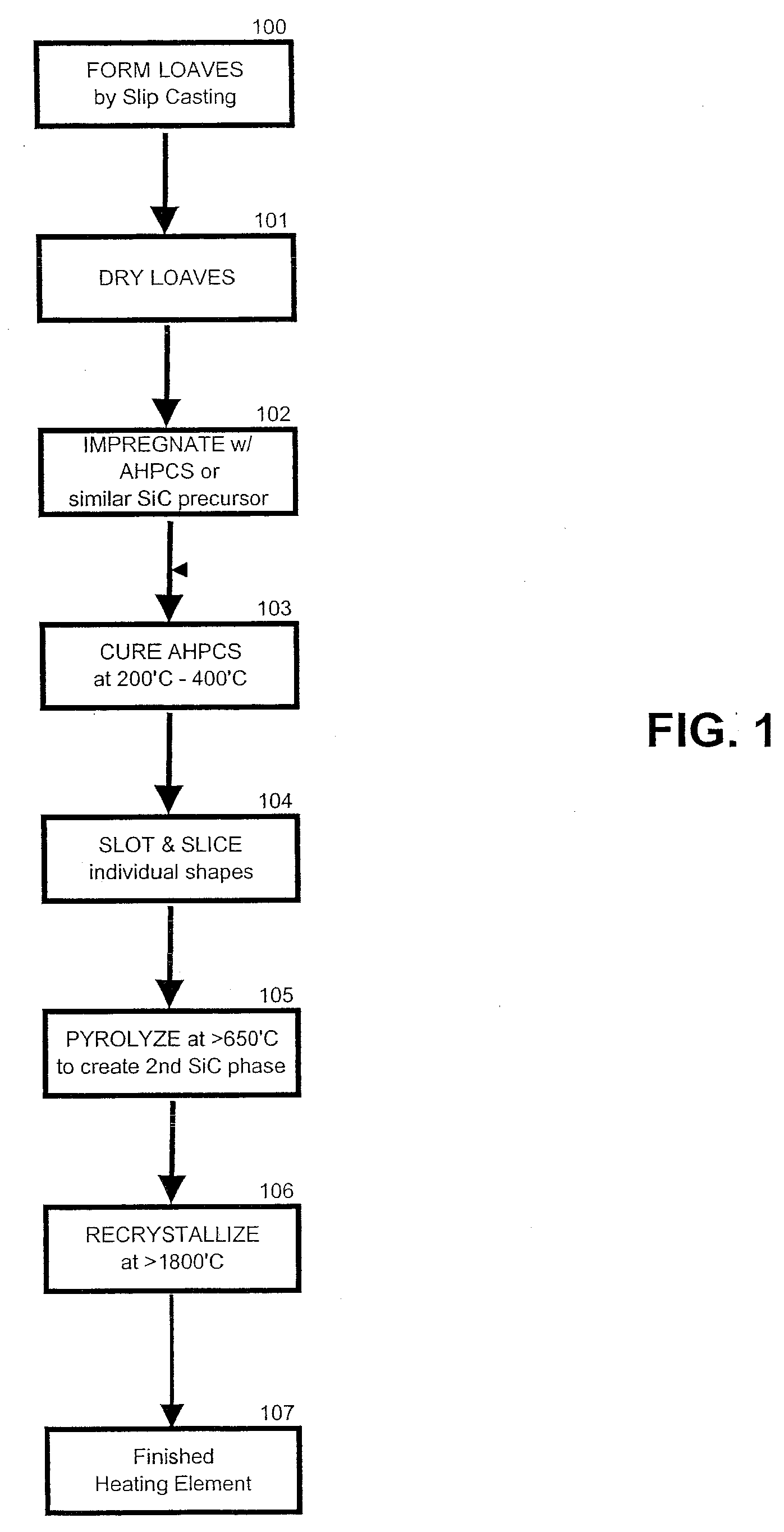

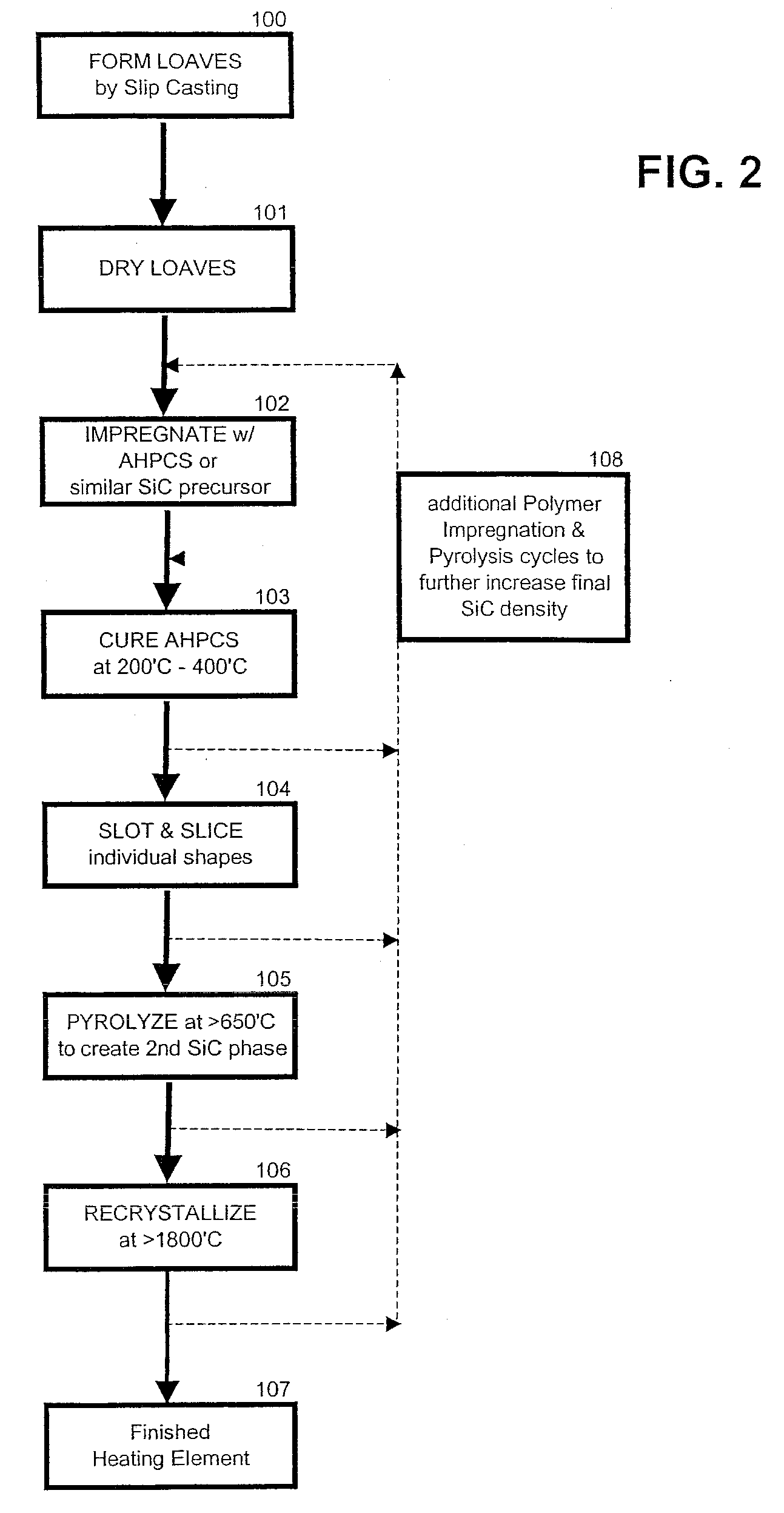

[0030]Reference will now be made in detail to the discussion supported by the accompanying illustrations. These drawings are in simplified form and are not to precise scale but are operative for assisting an understanding of the method herein. For purposes of convenience and clarity only, directional terms, such as top, bottom, up, down, over, above, and below may be used with respect to the drawings. These and similar directional terms should not be construed to limit the scope of the invention in any manner.

[0031]This invention relates to novel electrical devices, including the hot surface igniters discussed above, fabricated from polycrystalline silicon carbide (SiC) and methods for forming the same. However, it shall be recognized that as used herein a hot surface igniter is merely a representative example wherein the heating element portion is composed of silicon carbide, that the present invention is not limited thereto and has broader applications throughout the industry.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com