Method for manufacturing heat resisting member applicable to an exhaust gas guide assembly with improved heat resistance for VGS turbocharger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0086]Embodiment 1 is an embodiment in which the presence of nonmetallic matter present in a heat resisting metal member is decreased and the size of nonmetallic matter is reduced. For this purpose, a method or process, such as calcium injection, a heating pressurization treatment, a pure oxygen blowing refining treatment or the like, is applied to the heat resisting metal member. More specifically, the manufacturing procedure is as follows.

(i) Decrease of Nonmetallic Inclusions in the Heat Resisting Metal Member

[0087]Calcium injection during a refining process decreases generation of nonmetallic inclusions, i.e. oxides (type B and type C inclusions) as well as sulfides (type A inclusions) by discharging sulfur, silicon, aluminum and the like as calcium compounds. Furthermore, by a pure oxygen blowing refining treatment, nonmetallic inclusions of type B and type C are decreased by discharging oxides as slag.

(ii) Reduction of the Size of Nonmetallic Inclusions in the Heat Resisting M...

embodiment 2

[0091]Embodiment 2 is an embodiment in which the heat resisting member (alloy) is manufactured according to the common procedure. Three examples embodied are shown in Table 1.

[0092]The reason for limiting the amount of each component in the alloy is as follows.

[0093]C of not more than 0.05% is to reduce sensitization susceptibility.

[0094]Mn of not less than 1% is to delay generation of a σ phase.

[0095]Ni of not less than 15% is to increase free energy for generating the σ phase.

[0096]Cr of not more than 30% is to increase free energy for generating the σ phase.

[0097]Ti of not less than 0.1% is to generate a γ′ phase.

[0098]Al of not less than 0.1% is to generate the γ′ phase.

[0099]Ce or La of not less than 0.05% is to suppress generation of an α phase.

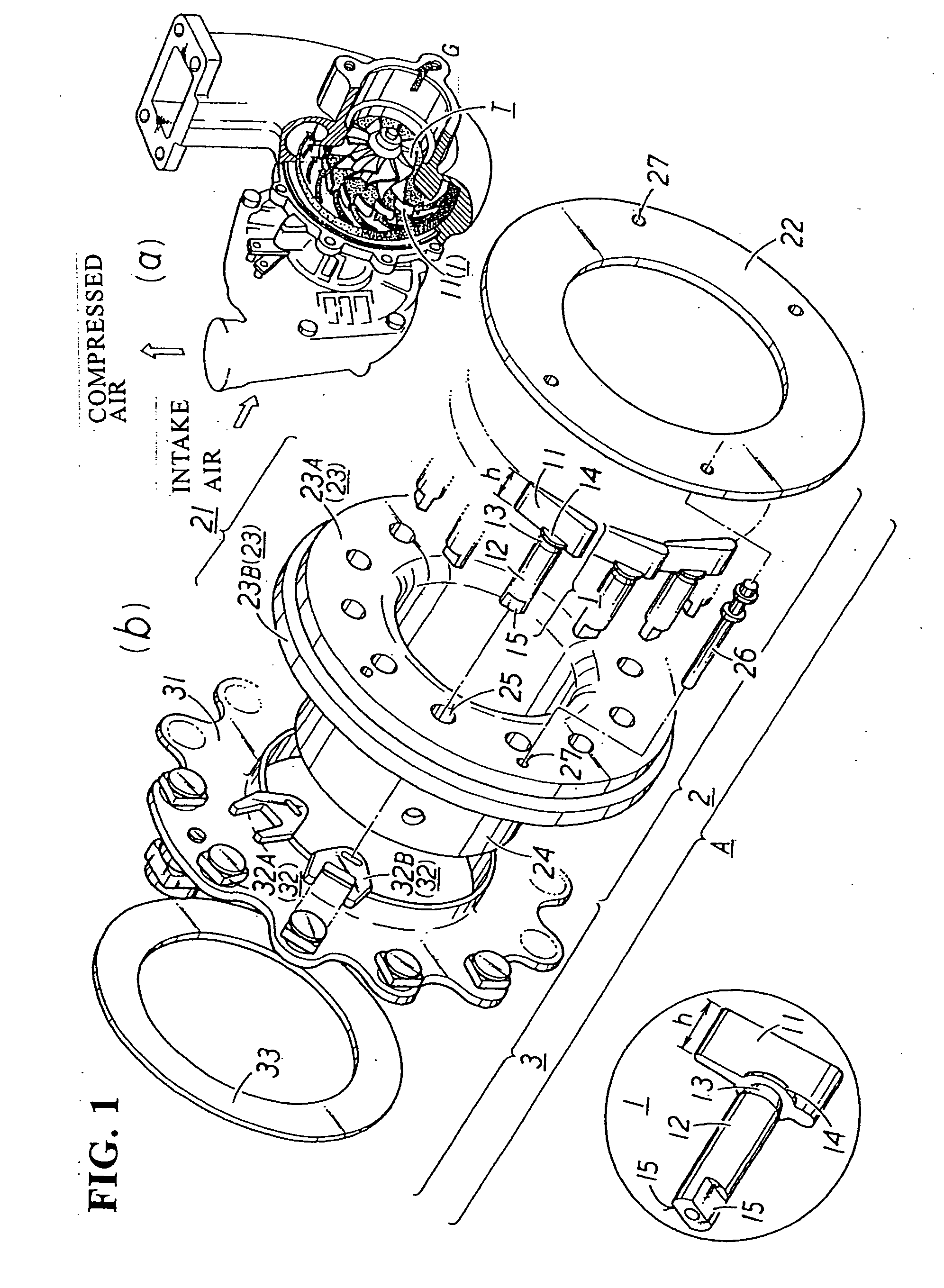

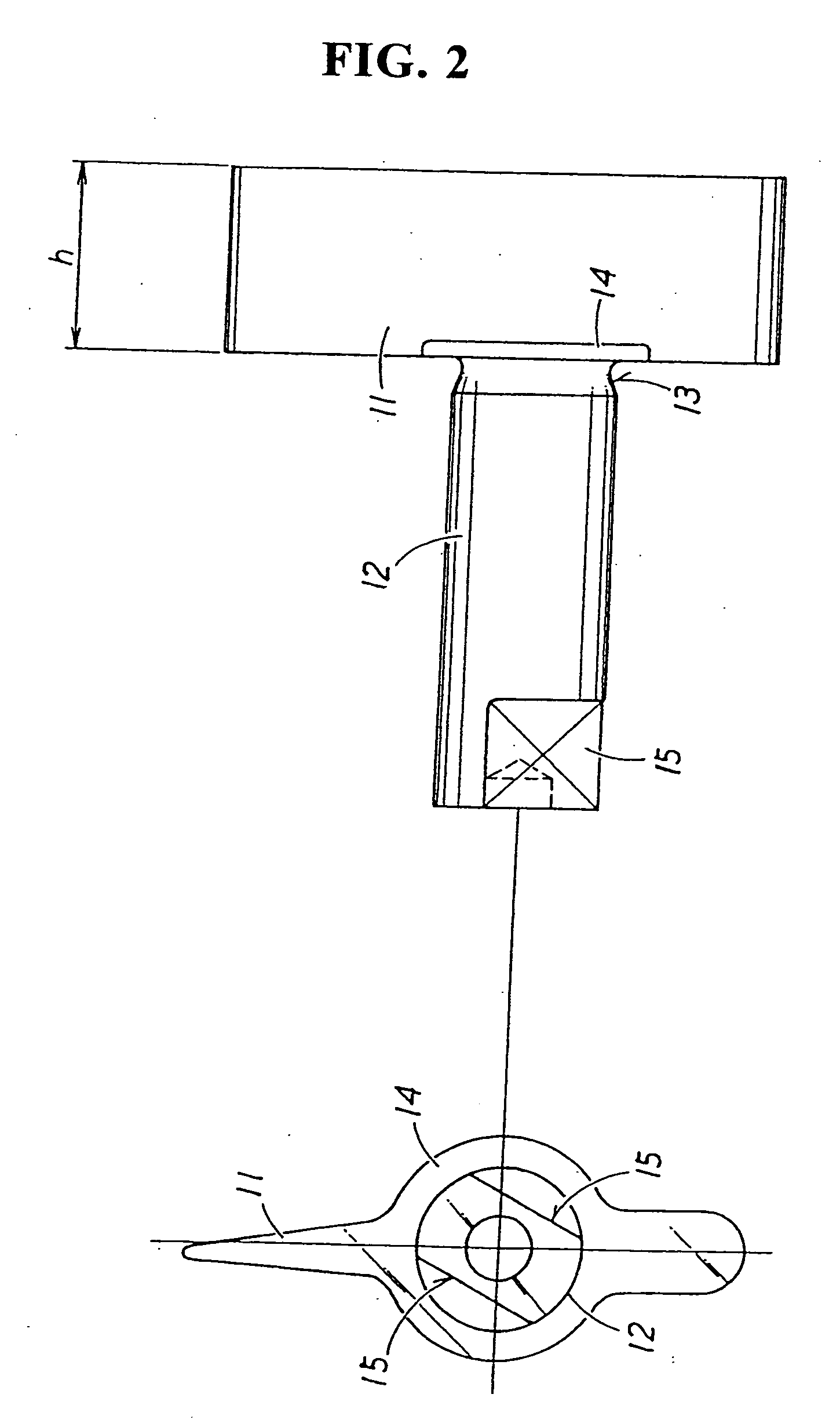

(i) Manufacture of the Exhaust Gas Guide Assembly

[0100]A basic material is manufactured by executing to it predetermined control of the above ingredients in the purifying process in a converter, thereafter, through the ordinary processe...

embodiment 3

[0106]Embodiment 3 is an embodiment and the alloy of this embodiment is manufactured according to the common procedure. Three examples embodied are shown in Table 4.

[0107]The reason for limiting the amount of each component in the alloy is as follows.

[0108]W of not less than 0.3% is to cause tempering secondary hardening to occur effectively and at a high temperature.

[0109]V of not less than 1.0% is to cause tempering secondary hardening to occur effectively and at a high temperature.

[0110]Mo of not less than 1.0% is to cause tempering secondary hardening to occur effectively and at a high temperature.

[0111]Hf of not less than 0.5% is to cause tempering secondary hardening to occur effectively and at a high temperature.

(i) Manufacture of the Exhaust Gas Guide Assembly

[0112]A stainless steel raw material is manufactured by controlling the composition in a refining process in a converter and further improving the accuracy of the composition in a secondary refining process, thereafter,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Wear resistance | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com