Processing of Metal Values from Concentrates

a technology of concentrates and metal values, applied in the direction of process efficiency improvement, etc., can solve the problems of high cost and technical disincentives, the kinetics of the copper leaching stage, and the pyrometallurgical treatment of arsenic-containing metal sulphide minerals is generally regarded as technical and economically undesirable, so as to improve the economics of gold and/or silver recovery from the leaching residue by cyanidation, and reduce the overall cyanide consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

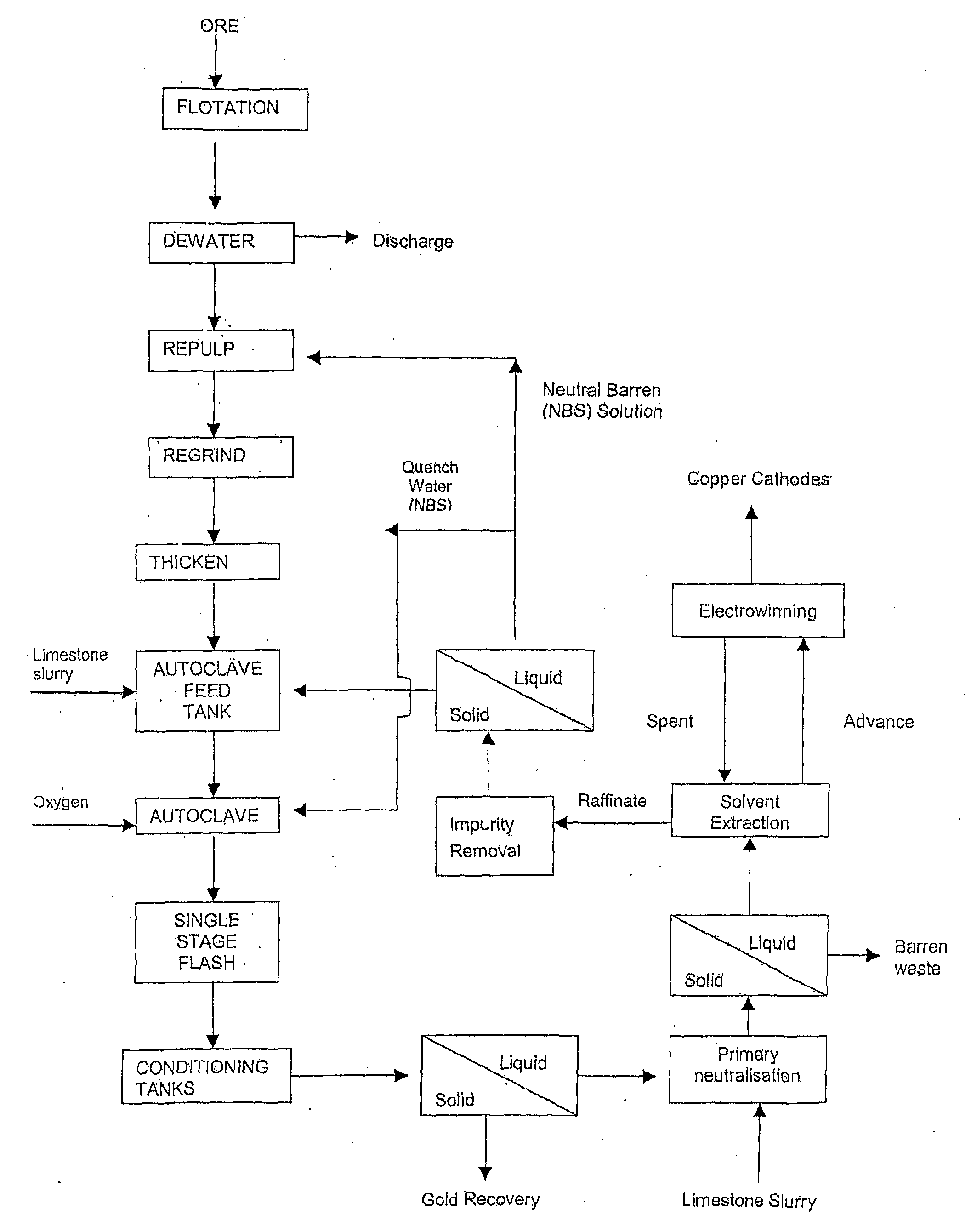

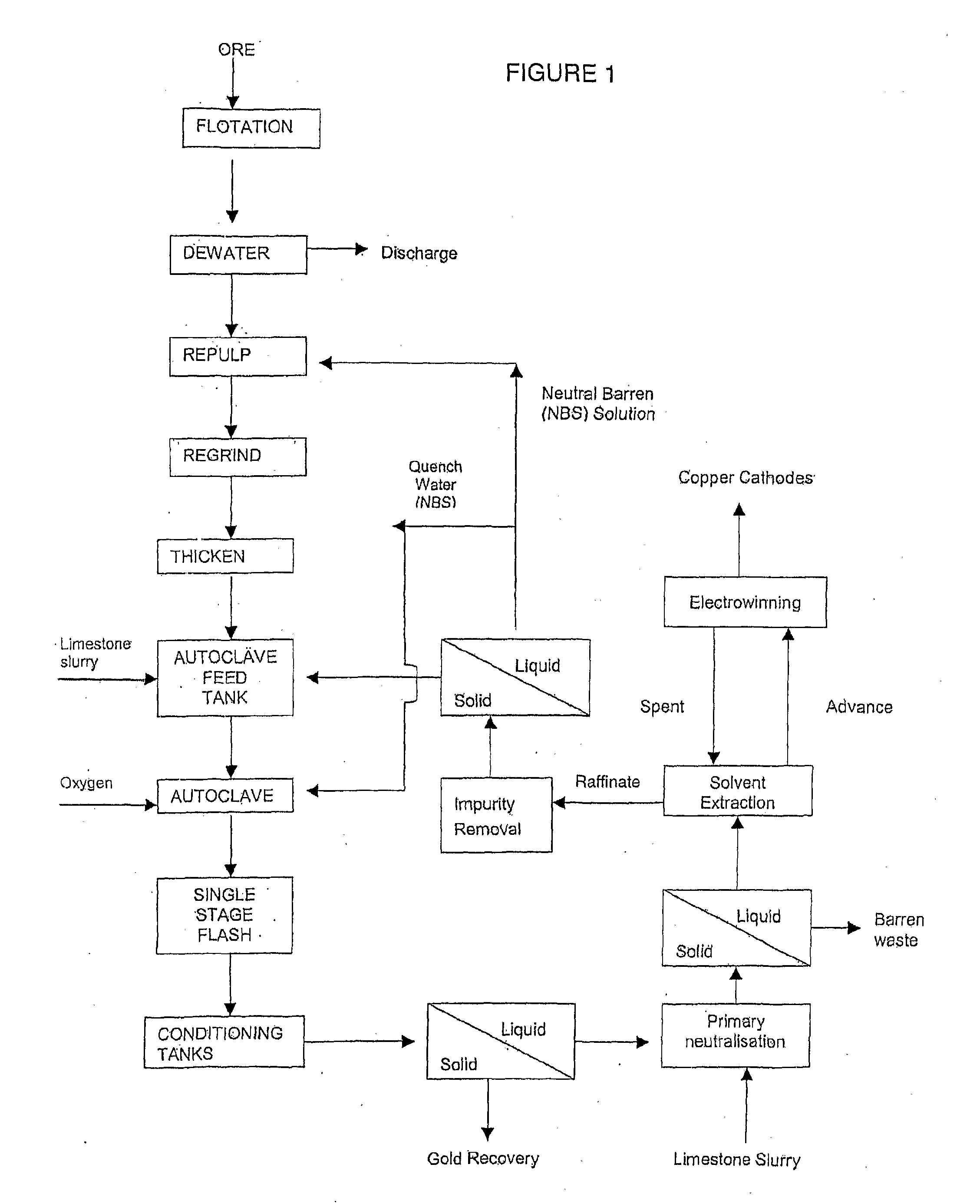

[0106]This example outlines the general scope of the preferred embodiments of the present invention as applied to the continuous processing of a run-of-mine tennantite-enargite-chalcopyrite-pyrite ore containing on average 1.5% Cu and 3.8 g / t gold derived in from the Chelopech (Bulgaria) resource. A simplified flowsheet of one preferred embodiment of the present invention is shown in FIG. 1.

[0107]After crushing and grinding, a copper concentrate typically containing 15.5% Cu, 24.8% Fe, 38.1% S, 4.7% As and 30 g / t Au is produced by rougher, scavenger and cleaner flotation banks using the appropriate flotation reagent regime. The copper concentrate is directed to a copper concentrate dewatering circuit where the free moisture is reduced to about 10%.

[0108]The copper concentrate is repulped in neutral barren solution (NBS) derived from the downstream copper recovery circuit (solvent extraction and electrowinning) that typically contains about 42 g / L MgSO4 and 15 g ZnSO4 at pH 8.5, prio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| Oxygen Reduction Potential | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com