Electrical Antifuse and Method of Programming

a technology of anti-fuses and circuits, applied in the direction of electrical equipment, semiconductor devices, semiconductor/solid-state device details, etc., can solve the problems of high programming voltage, severe trade-offs, and numerous serious drawbacks of anti-fuses, and achieve rapid and reliable programming, low voltage, and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

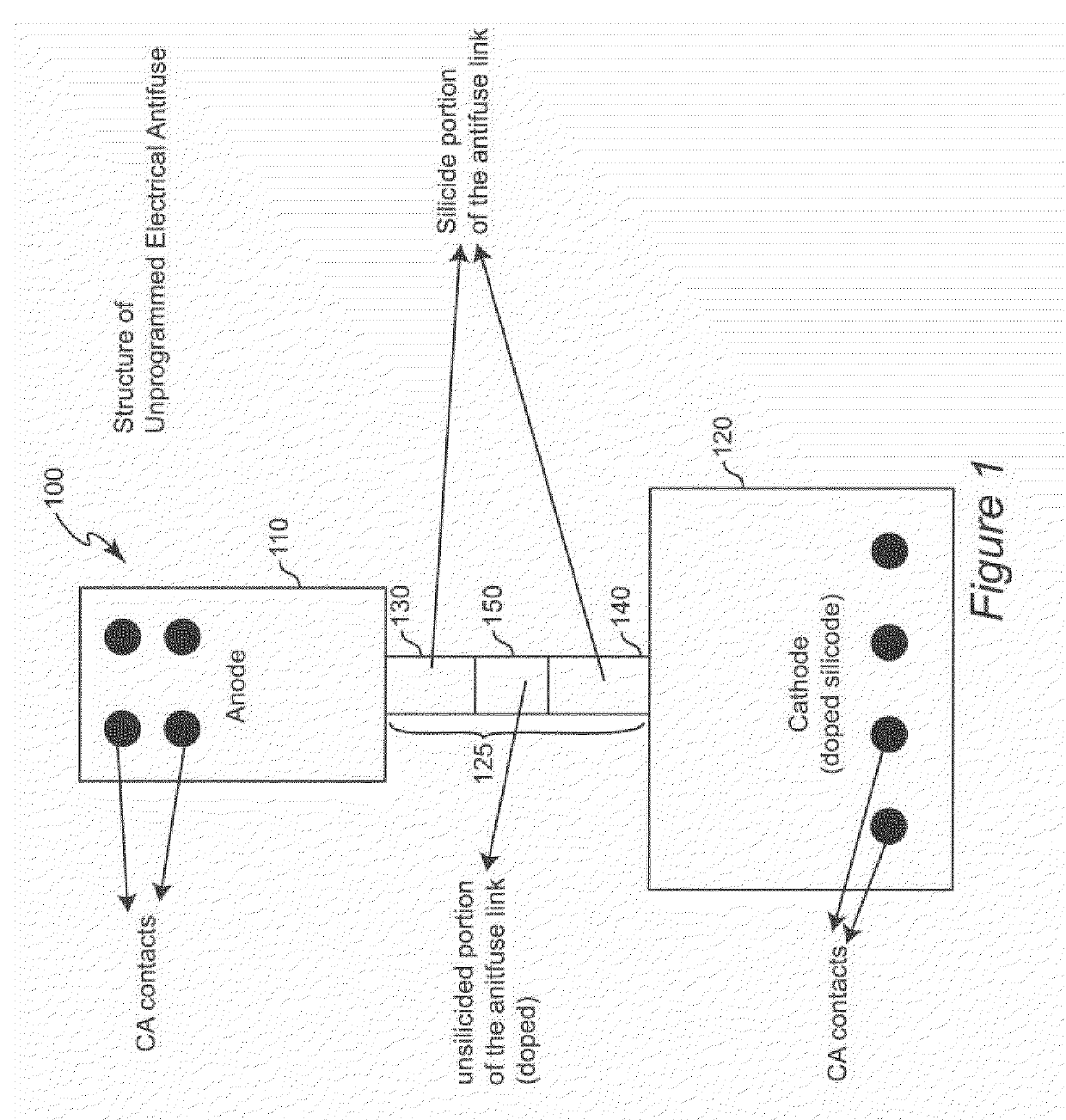

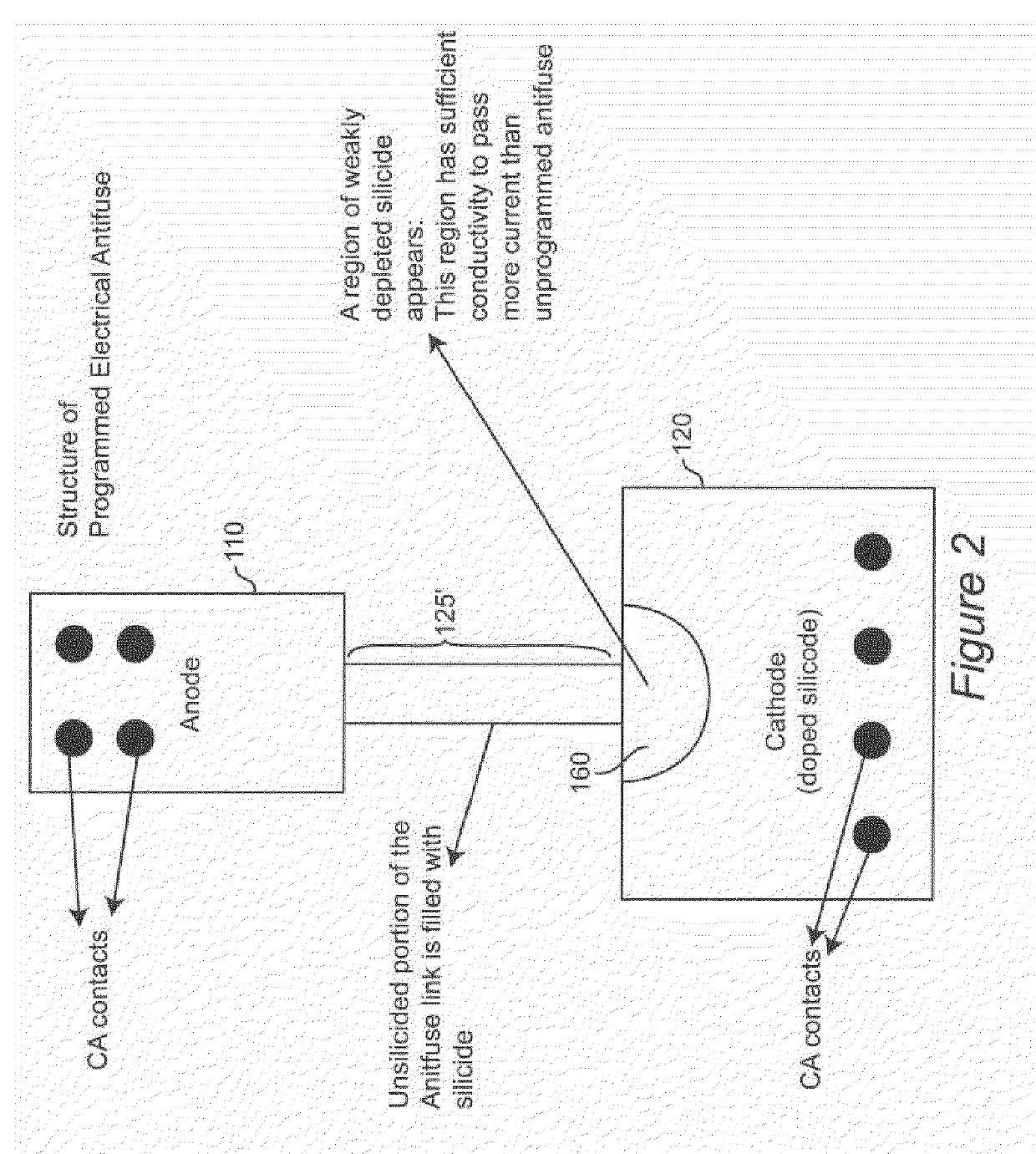

[0030]Referring now to the drawings, and more particularly to FIG. 1, there is shown, in plan view, a schematic representation of an antifuse in accordance with the present invention. Basically, the antifuse 100 in accordance with the present invention includes two enlarged rectangular terminal portions designated as an anode 110 and a cathode 120, each of which preferably comprises a stack of a polycrystalline silicon containing material layer and a silicide containing layer. The present invention can also be implemented in other technologies such as in a monocrystal line layer over a buried oxide (BOX) layer in semiconductor-on-insulator technology or other embodiments which will be apparent to those skilled in the art in view of the following discussion which, for clarity, will be provided in connection with the preferred polysilicon structure but which should be understood as inclusive of and comprehending other technologies and materials.

[0031]The preferred polycrystalline sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voltages | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com