Method for influenza virus protection

a technology of influenza virus and purification method, which is applied in the field of influenza virus protection, can solve the problems of high mortality rate of epidemics, significant fall in the mortality rate of high-risk populations, and high contamination of vaccines, so as to achieve simple process scale up, reduce contamination level, and maintain influenza virus potency. effect of immunogenicity and/or infectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

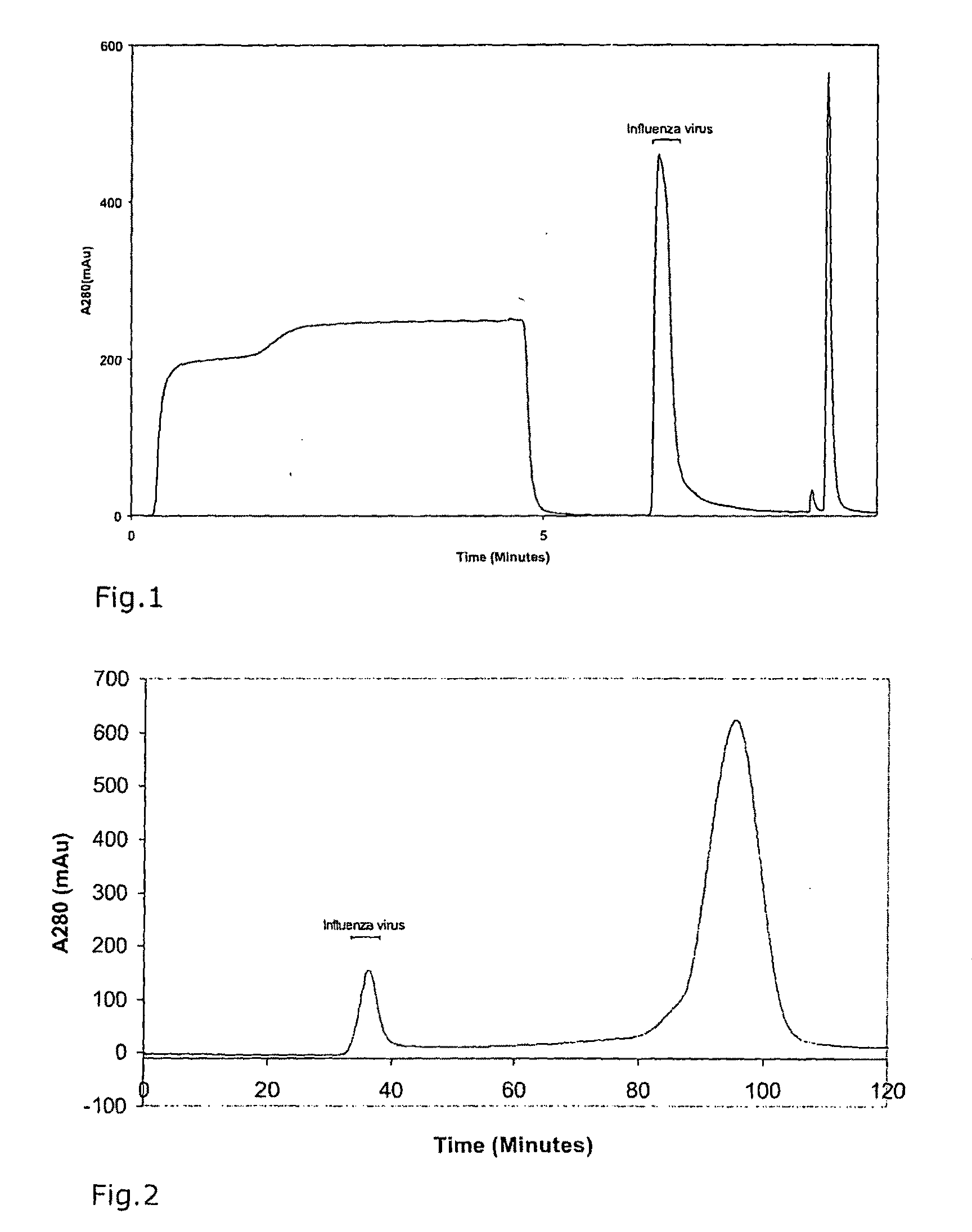

[0079]This example demonstrates the preferred influenza virus purification method of the present invention using tangential flow filtration, anion exchange chromatography, size exclusion chromatography and sterile filtration followed each other in this order.

[0080]Influenza virus reassortment of A / PR / 8 / 34 Mt. Sinai with deletion in NS1 gene and IVR-116 was cultivated on Vero cells in Gibco™ OptiPRO™ SFM medium. Approximately 15 000 mL of cell lysate was clarified by centrifugation at 2400 rpm at room temperature for 10 minutes. The supernatant was collected and filtered through a Sartobran P 500 cm2 capsule filter with a cellulose acetate membrane, 0.65-0.45 μm.

[0081]The filtrate was concentrated by tangential flow filtration using Proflux system (Millipore) and hollow fibre TFF cartridge with 750 kDa nominal cut-off and 0.12 m2 area (GE Healthcare, UFP-750-E-5A). The trans-membrane pressure was 0.2 to 0.3 bar. The final volume of concentrate was 1400 ml.

[0082]The concentrate was fu...

example 2

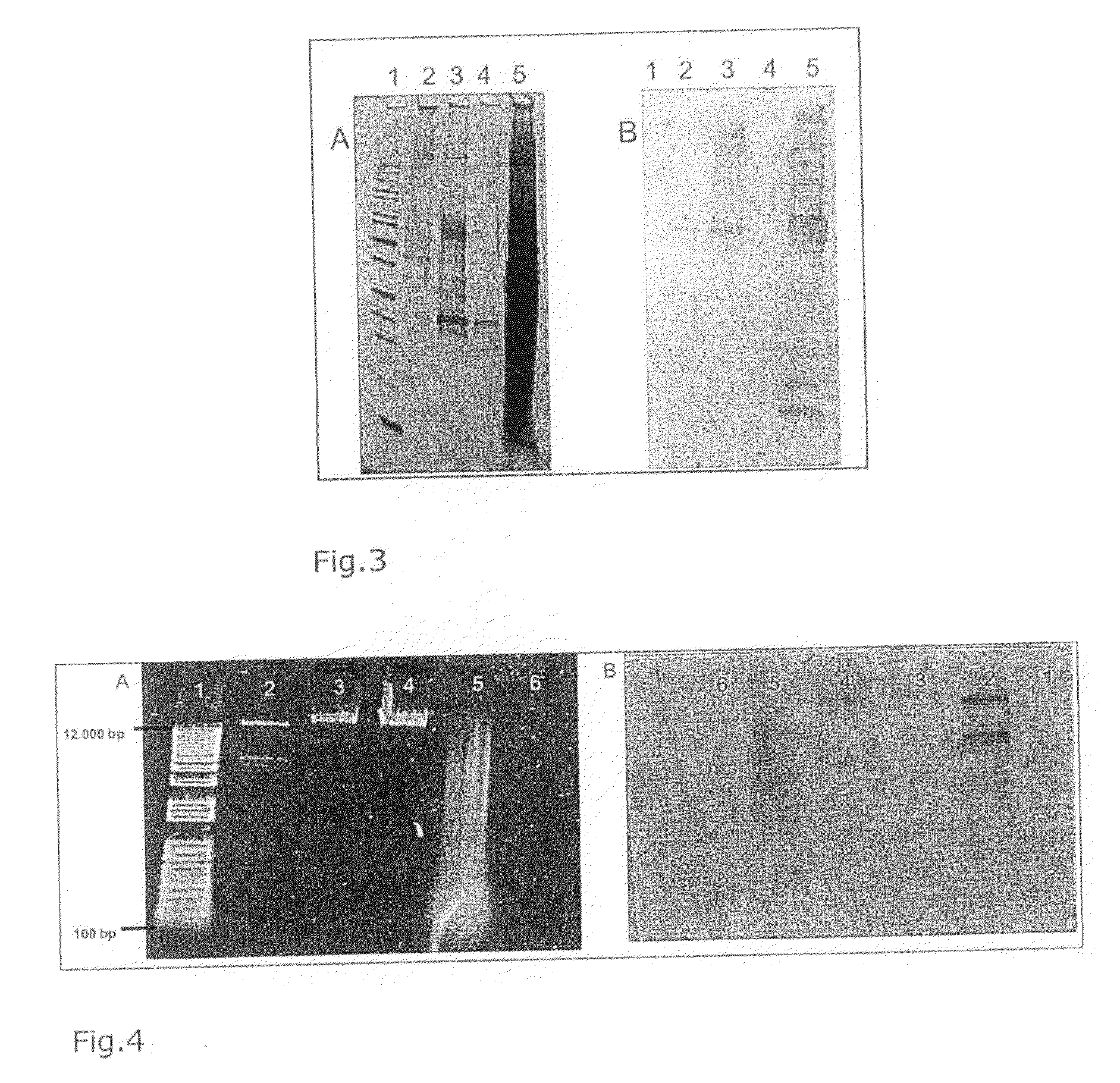

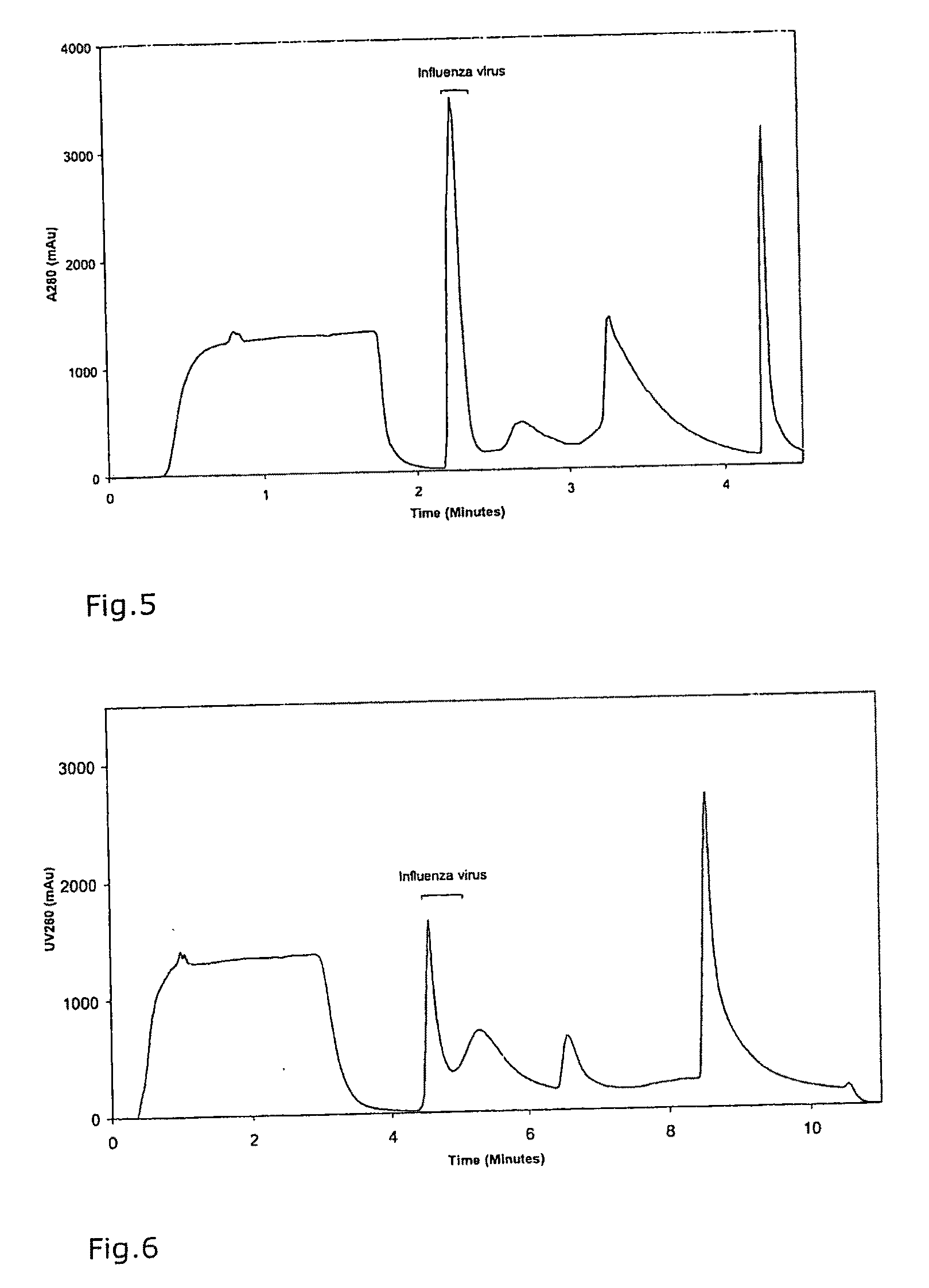

[0090]In this example three different anion exchange functional groups are compared. The example illustrates that different anion exchange functional groups can be used for the purification of influenza virus particles.

[0091]Influenza virus reasortment of A / PR / 8 / 34 Mt. Sinai with deletion in NS1 gene and IVR-116 was cultivated on Vero cells in Gibco™ OptiPRO™ SFM medium. The cell lysate was clarified by centrifugation at 2400 rpm at room temperature for 10 minutes. The supernatant was collected and concentrated by tangential flow filtration using a Labscale TFF system (Millipore) and a Pellicone Biomax 300 kDa cut-off membrane (Millipore, PXB3 00C 50). The concentrate was used for comparison of three CIM® disks monolithic columns: CIM® QA disk, CIM® DEAE disk, and CIM® EDA disk monolithic column (BIA Separations). Following buffers were used:

[0092]Buffer A: 50 mM HEPES (pH=7.5), Buffer B: 50 mM HEPES / 0.3M NaCl (pH=7.5), Buffer C: 50 mM HEPES / 1.5M NaCl (pH=7.5).

[0093]On each column 6...

example 3

[0094]In this example three different types of chromatographic support are compared. The example illustrates that the porous particle support, membranes and monoliths can be used for the purification of influenza virus.

[0095]Influenza virus reasortment of A / PR / 8 / 34 Mt. Sinai with deletion in NS1 gene and IVR-116 was cultivated on Vero cells in Gibco™ OptiPRO™ SFM medium. The cell lysate was clarified by centrifugation at 2400 rpm at room temperature for 10 minutes. The supernatant was collected and concentrated by a tangential flow filtration using Labscale TFF system (Millipore) and a Pellicone Biomax 300 kDa cut-off membrane (Millipore, PXB3 00C 50). The concentrate was used for the comparison of three different chromatographic supports: CIM® QA disk monolithic column (BIA Separations), Q Sepharose XL virus licensed (GE Healthcare), and Mustang Q coin (Pall). The following buffers were used:

[0096]Buffer A: 50 mM HEPES (pH=7.5), Buffer B: 50 mM HEPES / 0.3M NaCl (pH=7.5), Buffer C: 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore sizes | aaaaa | aaaaa |

| pore sizes | aaaaa | aaaaa |

| volumes | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com