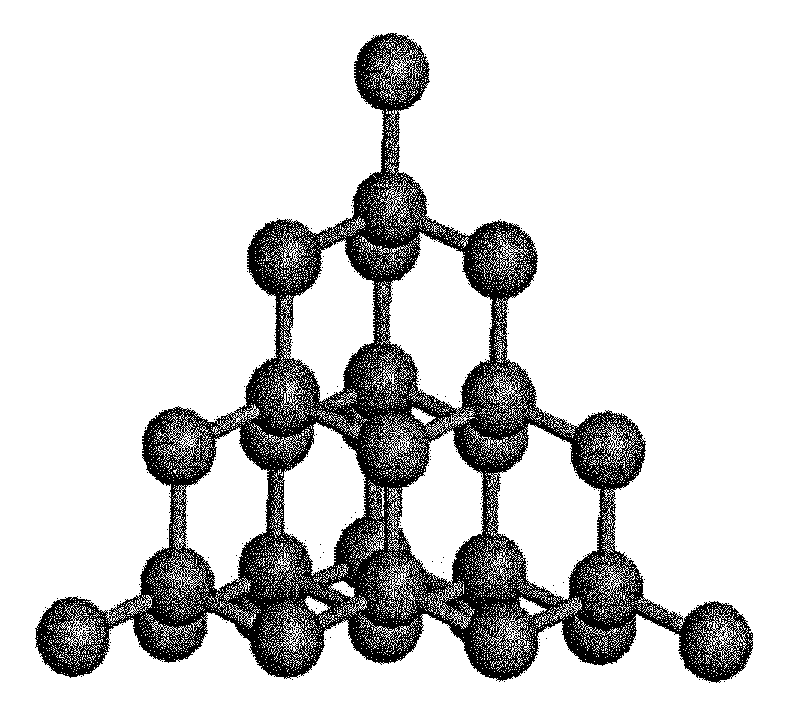

Porous Polymer and Synthetic Method Thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

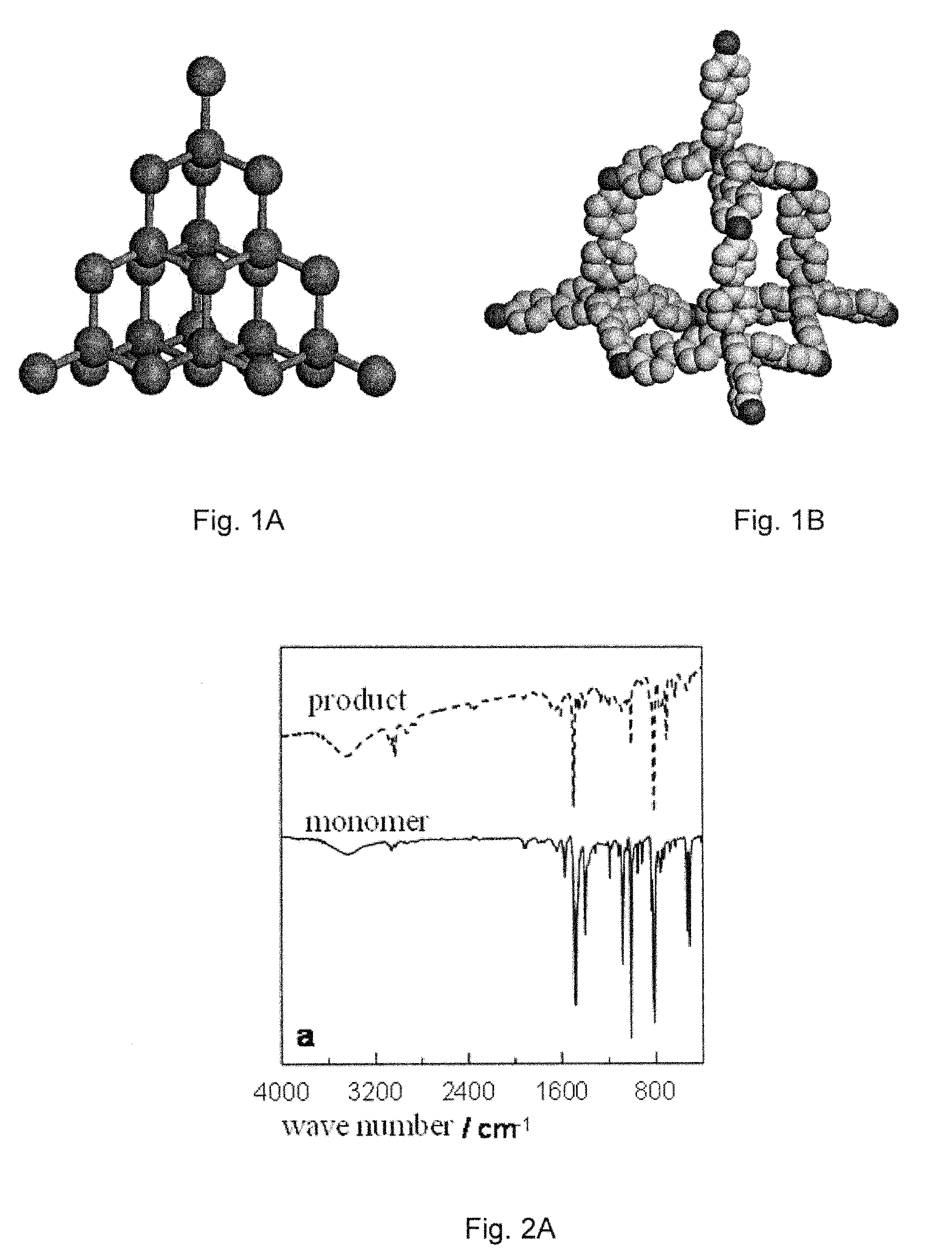

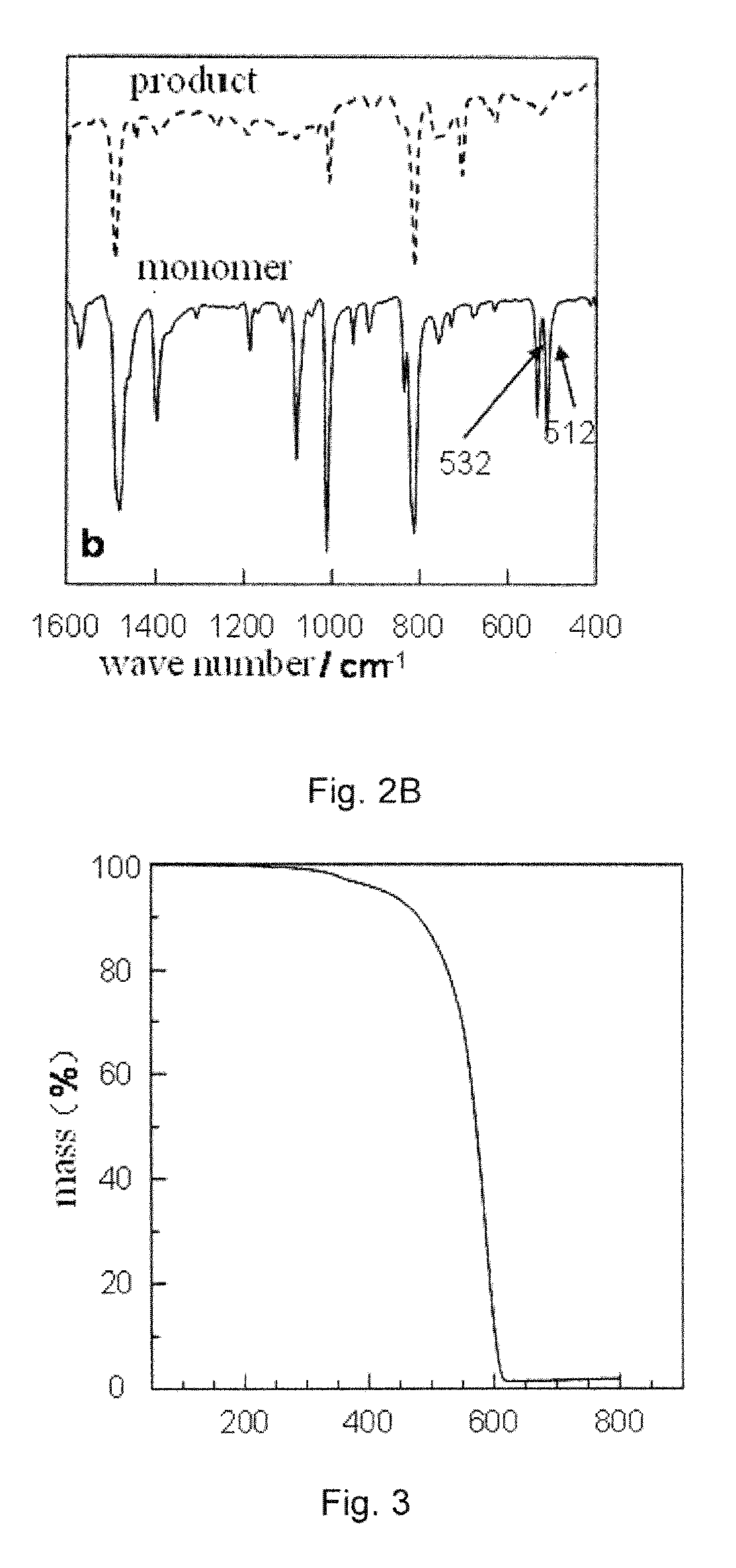

example 1

[0179](1) To 1 mL of DMF solution was added bis(1,5-cycloocta-1,5-diene)nickel(0) (1 g), 2, 2′-bipyridyl (0.568 g) and 1,5-cycloocta-1,5-diene (0.4 mL) and the mixture was heated at 50° C. for 0.5 hour;

[0180](2) To the resultant mixture was added 3 mL tetrakis(4-bromophenyl)silane (DMF solution, 0.2M), and stirred at that temperature for 60 hours;

[0181](3) After cooling to room temperature, conc. HCl was added to the reaction mixture;

[0182](4) After filtration the residue was washed with 100 mL hot water, THF, and CHCl3, respectively;

[0183](5) After dried in vacuum at 3-10 mmHg for 10-40 hours at 80-200° C., the pure porous polymer was obtained with 76% yield.

example 2

[0184]The procedure is repeated in a manner similar to that of step (1) of example 1. The reaction mixture was injected into a stainless steel autoclave at 90° C., which yields a polymer with properties very similar to those of the polymer made in example 1.

example 3

[0185]The procedure is repeated in a manner similar to that of example 1. The monomer was changed to tetrakis(4-iodophenyl)methane, which yields a polymer (84% yield) with properties very similar to those of the polymer made in example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com