Sweetening compositions and processes for preparing them

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

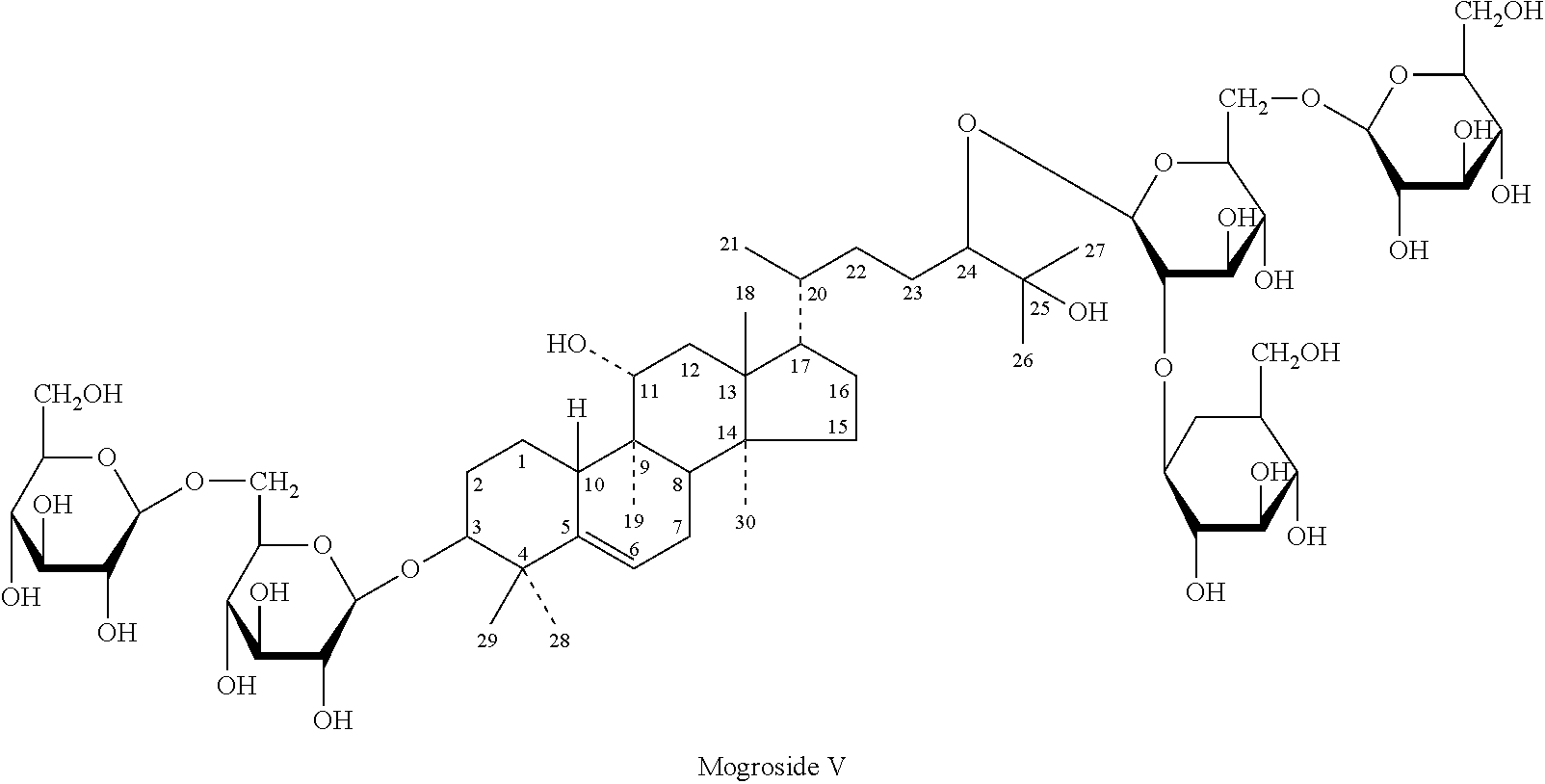

Image

Examples

example 1

[0106]Luo Han Guo fruit extract, (pH 4.2 and 6.2% w / w soluble solids by refractometer), was received frozen from Guilin, P R China. The Luo Han Guo extract had been prepared by the following method.

[0107]1.2 tonnes of good quality, fresh Luo Han fruit is mechanically shredded and dropped into a steam jacketed vat. 1,500 L of filtered water is added to the macerated fruit. The water is heated to 100° C. and the mixture is decocted for 45 minutes. After 45 minutes the decoction is drained off the fruit and filtered to remove large fruit particles. A further 1,500 L of water is added to the fruit remaining in the vat. The water is heated to 100° C. and the mixture is decocted for 45 minutes. After 45 minutes the decoction is drained off the fruit, filtered to remove large fruit particles, and combined with the decoction from the first cycle. This cycle is repeated one more time to give a total volume of 4,500 L of supernatant. The supernatant has soluble solids of between 3%-6.5%.

[0108...

example 2

[0127]Luo Han Guo fruit juice 4,500 L was hot water extracted from 1.2 tonne fruit using the method described in Example 1, then chill stored at 0 to −3° C. until processed. The juice was withdrawn from storage in 500 L batches and warmed in a steam jacketed open kettle to 45±5° C. The juice pH was 3.9 and availed 3.2% w / w soluble solids, (determined gravimetrically).

[0128]1. Removal of suspended solids to avert blinding of the harvesting adsorbent resin.

[0129]A proprietary pectinase enzyme preparation (Novozym 33056) 100 mL was added to each 500 L batch and the incubated mixture gently stirred for 30 minutes until a flock formed and began to settle, whereupon the temperature was rapidly raised to 85° C. to terminate the enzyme activity and pasteurise the juice. The liquid was then siphoned off into 50 L, food-grade polyethylene carboys, capped and left to cool. When below 65° C. the juice was filtered to optical clarity by pumping it through a plate filter fitted with double layers...

example 3

[0147]Luo Han Guo fruit juice 4,500 L was hot water extracted from 1.2 tonne fruit using the method described in Example 1.

[0148]1. Removal of suspended solids to avert blinding of the harvesting adsorbent resin.

[0149]The juice was filtered to optical clarity by pumping it through an ultra filtration unit with membranes having a molecular weight cut off of 100 kDa. The permeate was an optically clear, pale yellow juice.

[0150]2. Concentration of mogrosides by harvesting onto US-FDA compliant, adsorbent resin.

[0151]Commercially available divinylbenzene copolymer adsorbent resin, (Alimentech P470), was prepared for contact with food as defined in US FDA 21 CFR Ch. 1, 173.65, in a locally manufactured pressurised stainless steel column, by following the resin supplier's instructions. The filtered Luo Han extract, previously prepared according to Section 1, were pumped through the adsorbent resin under pressure at less than 50° C. flow vacillating between 30 and 50 L / min. The mogroside d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com