Porous Carbon Oxide Nanocomposite Electrodes for High Energy Density Supercapacitors

a carbon dioxide and supercapacitor technology, applied in the direction of graphene, electrolytic capacitors, chemistry apparatus and processes, etc., can solve the problems of affecting the performance of the supercapacitor, the cost of the electronic energy storage system is simply too high to penetrate major new markets, and the market has almost been completely displaced, etc., to achieve high capacitance, conduct electricity better, and high surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

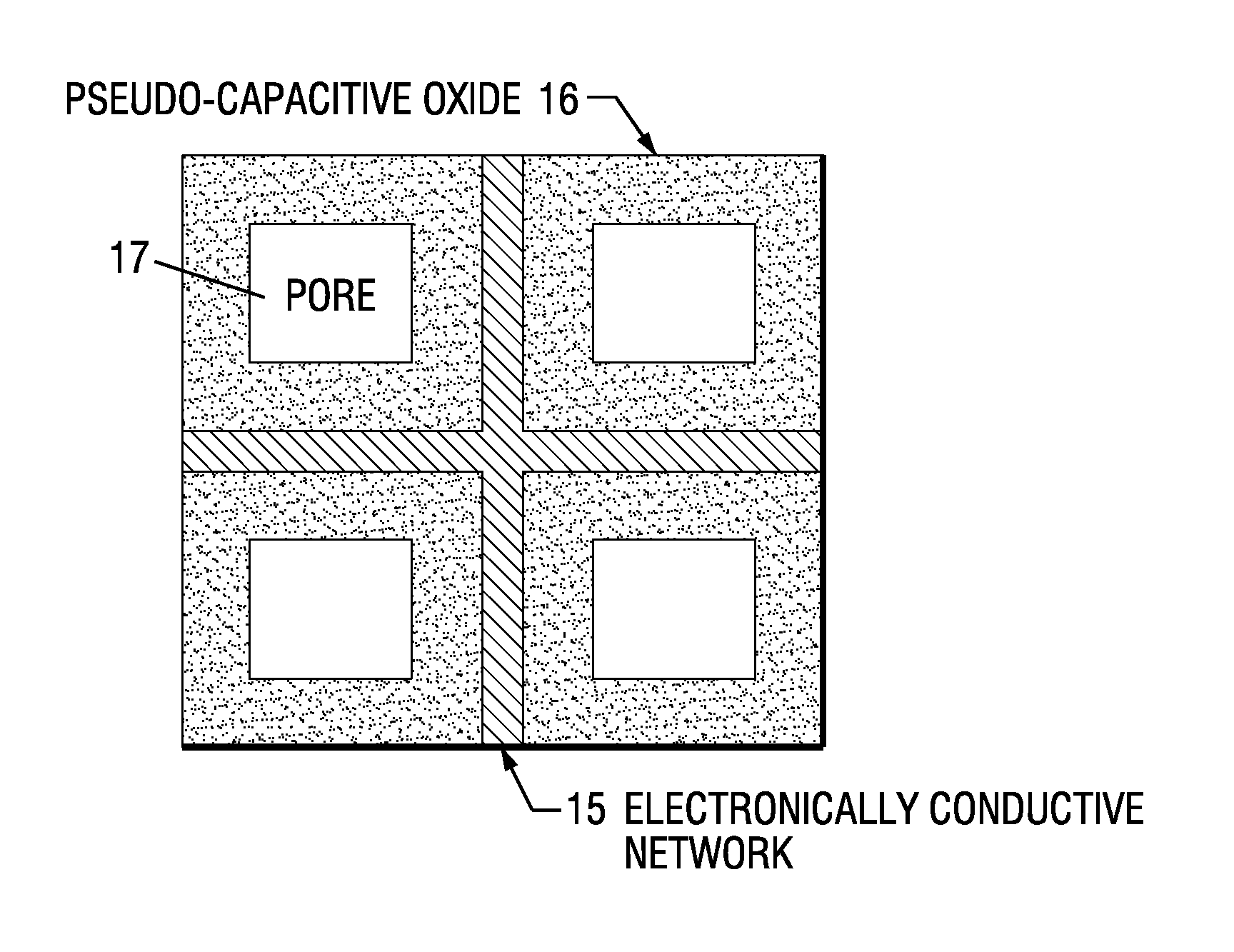

[0036]The invention describes a designed nanocomposite used as electrodes in a supercapacitor for increasing its energy density. As schematically shown in FIG. 3, a pseudo-capacitive oxide 16, whose practical application is hindered by its limited electrical conductivity, is supported by an electrically conductive network 15. Pores are shown as 17. On the other hand, as shown in FIG. 4, the nanocomposite can be produced by “decorating” the pores of a pseudo-capacitive skeleton 18 with carbon as the electrically conductive network 15′. Its surface area can be further increased by coating the carbon conductive network with the same or different pseudo-capacitive oxides 16′. Useful pseudo-capacitive oxides, 16 in FIGS. 3 and 16′ in FIG. 4, are selected from the group consisting of NiO, RuO2, SrO2, SrRuO3, MnO2 and mixtures thereof. Most preferably, NiO and MnO2. Useful carbons are selected from the group consisting of activated carbon, amorphous carbon, carbon nanotubes and graphene, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com