Hardmask composition having antireflective properties and method of patterning material on substrate using the same

a technology of antireflective properties and compositions, applied in the field of hardmask compositions for lithography, can solve the problems of resist not providing resistance to subsequent etching, difficult application of conventional hardmask materials to substrates, and further patterning may be required, so as to minimize the reflectivity between resists and underlying layers, the effect of high etch selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

synthesis example 1

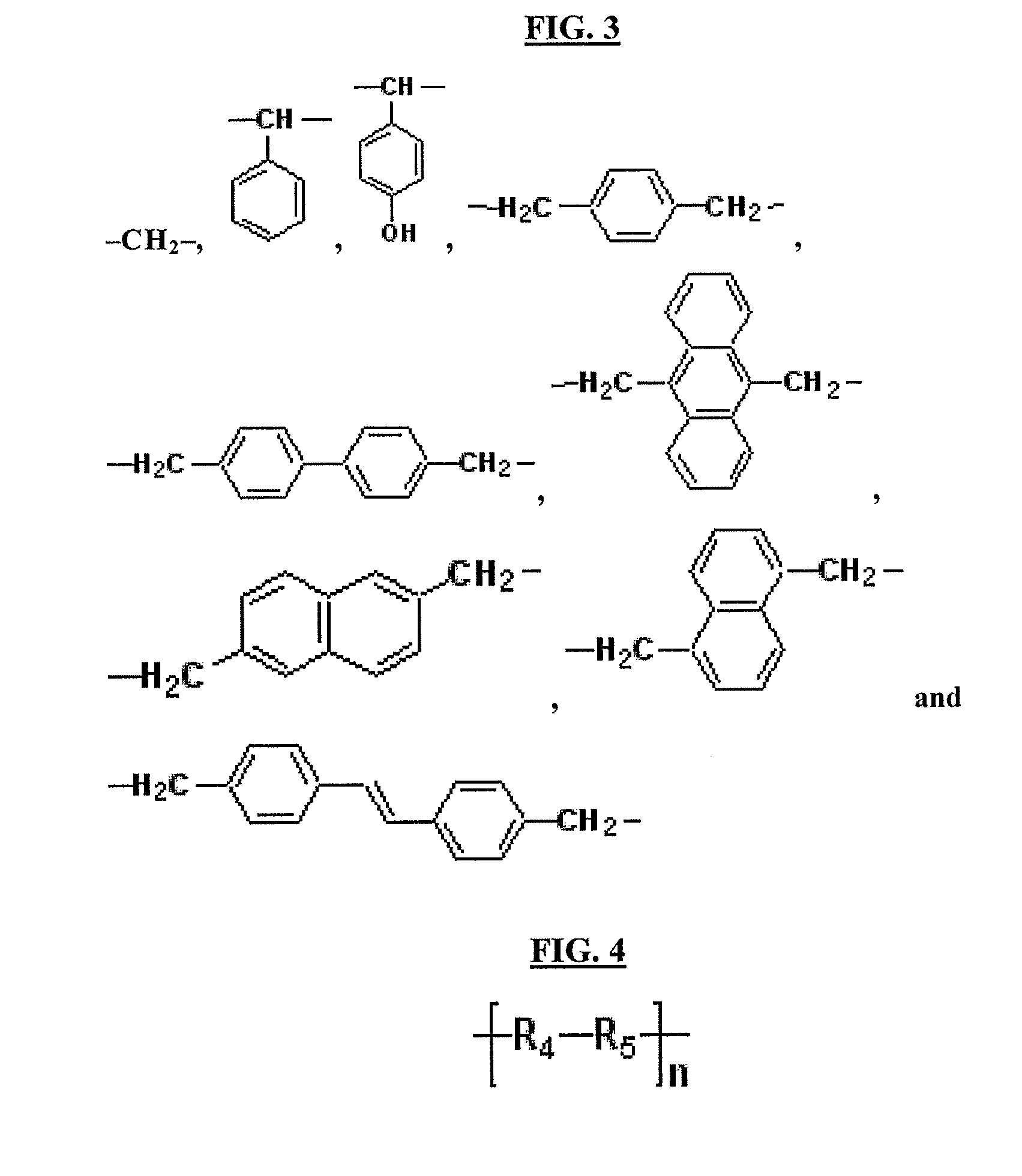

Synthesis of terpolymer of 9,9′-bishydroxynaphthylfluorene, 1-naphthol and 9,10-bismethoxymethylanthracene

[0094]450.5 g (1.0 mol) of 9,9′-bishydroxynaphthylfluorene, 144.2 g (1.0 mol) of 1-naphthol, 3.1 g (0.02 mol) of diethyl sulfate and 350 g of propylene glycol monomethyl ether were completely dissolved with stirring in a 3 L three-neck flask equipped with a mechanical agitator and a condenser while maintaining the temperature of the reactor at 100° C.

[0095]10 minutes after the dissolution, 532.7 g of (2.0 mol) of 9,10-bismethoxymethylanthracene was dropped into the solution, and then the resulting mixture was allowed to react at 120° C. for 15 hours. To the reaction mixture was added 2.98 g (0.02 mol) of triethanolamine as a neutralizing agent to quench the reaction.

[0096]After completion of the reaction, a water / methanol mixture was used to remove the acid from the reaction mixture, and methanol was used to remove low-molecular weight compounds containing the oligomers and mono...

synthesis example 2

Synthesis of terpolymer of 9,9′-bishydroxynaphthylfluorene, 1-hydroxypyrene and 1,4-bismethoxymethylbenzene

[0097]The procedure of Synthesis Example 1 was repeated, except that 218.3 g (1 mol) of 1-hydroxypyrene was added instead of 144.2 g of 1-naphthol, and 332.9 g (2 mol) of 1,4-bismethoxymethylbenzene was added instead of 532.7 g of (2.0 mol) of 9,10-bismethoxymethylanthracene, yielding the copolymer of Formula 7:

[0098]The molecular weight and the polydispersity of the copolymer were measured by gel permeation chromatography (GPC) in tetrahydrofuran. As a result, the copolymer was found to have a molecular weight of 11,000 (n=10, m=11) and a polydispersity of 2.2.

synthesis example 3

Synthesis of terpolymer of 9,9′-bishydroxynaphthylfluorene, phenol and formaldehyde

[0099]The procedure of Synthesis Example 1 was repeated, except that 94.1 g (1.0 mol) of phenol was added instead of 144.2 g of 1-naphthol, and 60.1 g (2 mol) of formaldehyde was added instead of 532.7 g of (2.0 mol) of 9,10-bismethoxymethylanthracene, yielding the copolymer of Formula 8:

[0100]The molecular weight and the polydispersity of the copolymer were measured by gel permeation chromatography (GPC) in tetrahydrofuran. As a result, the copolymer was found to have a molecular weight of 10,000 (n=8, m=8) and a polydispersity of 1.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelengths | aaaaa | aaaaa |

| wavelengths | aaaaa | aaaaa |

| wavelengths | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com