Method For Processing Hydrocarbon Pyrolysis Effluent

a technology of hydrocarbon pyrolysis and effluent, which is applied in the direction of hydrocarbon oil treatment products, effluent separation, gaseous mixture working up, etc., can solve the problems of ineffective heat transfer, limited outlet temperature on the process side of the tle, and only a portion of furnace effluent heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

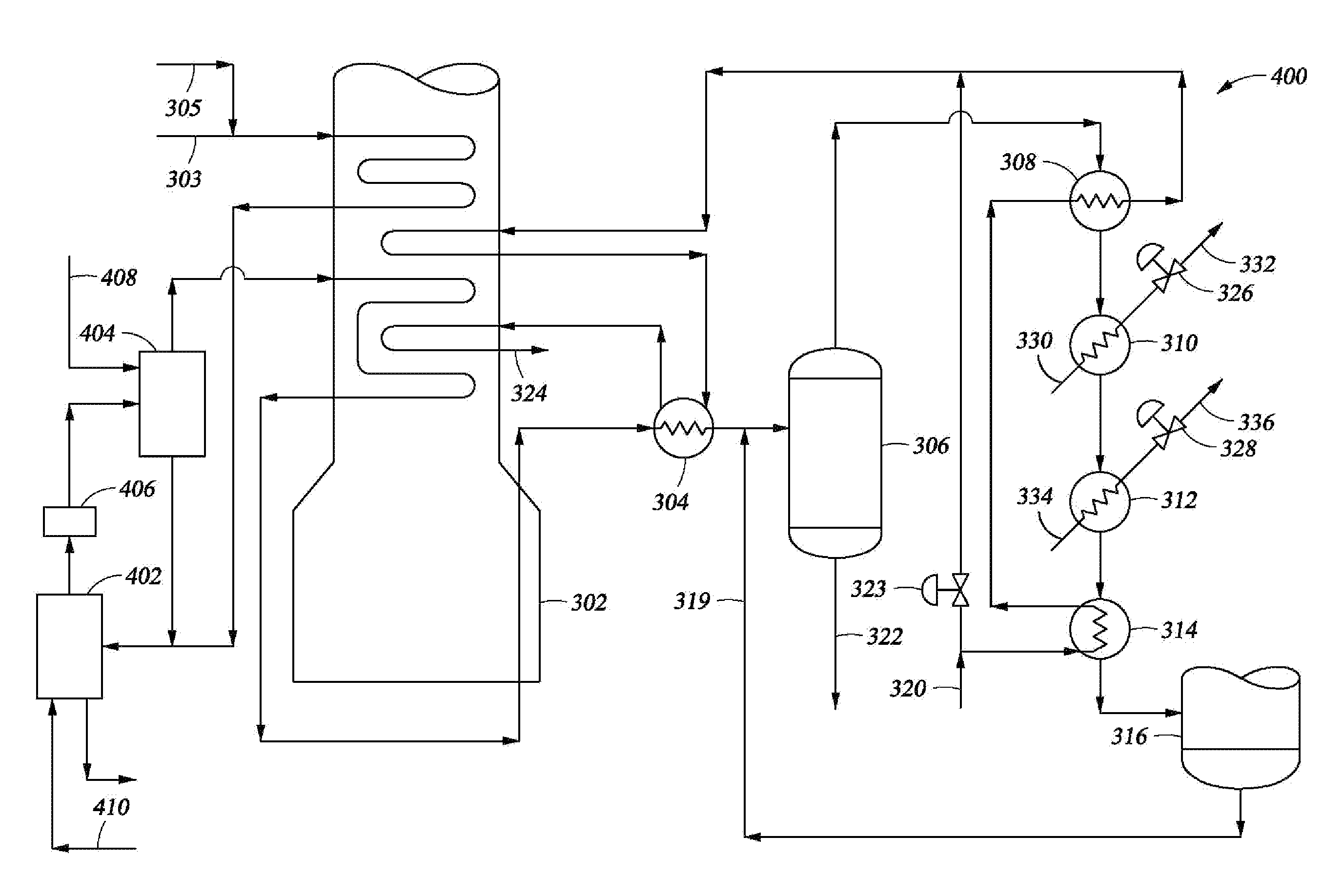

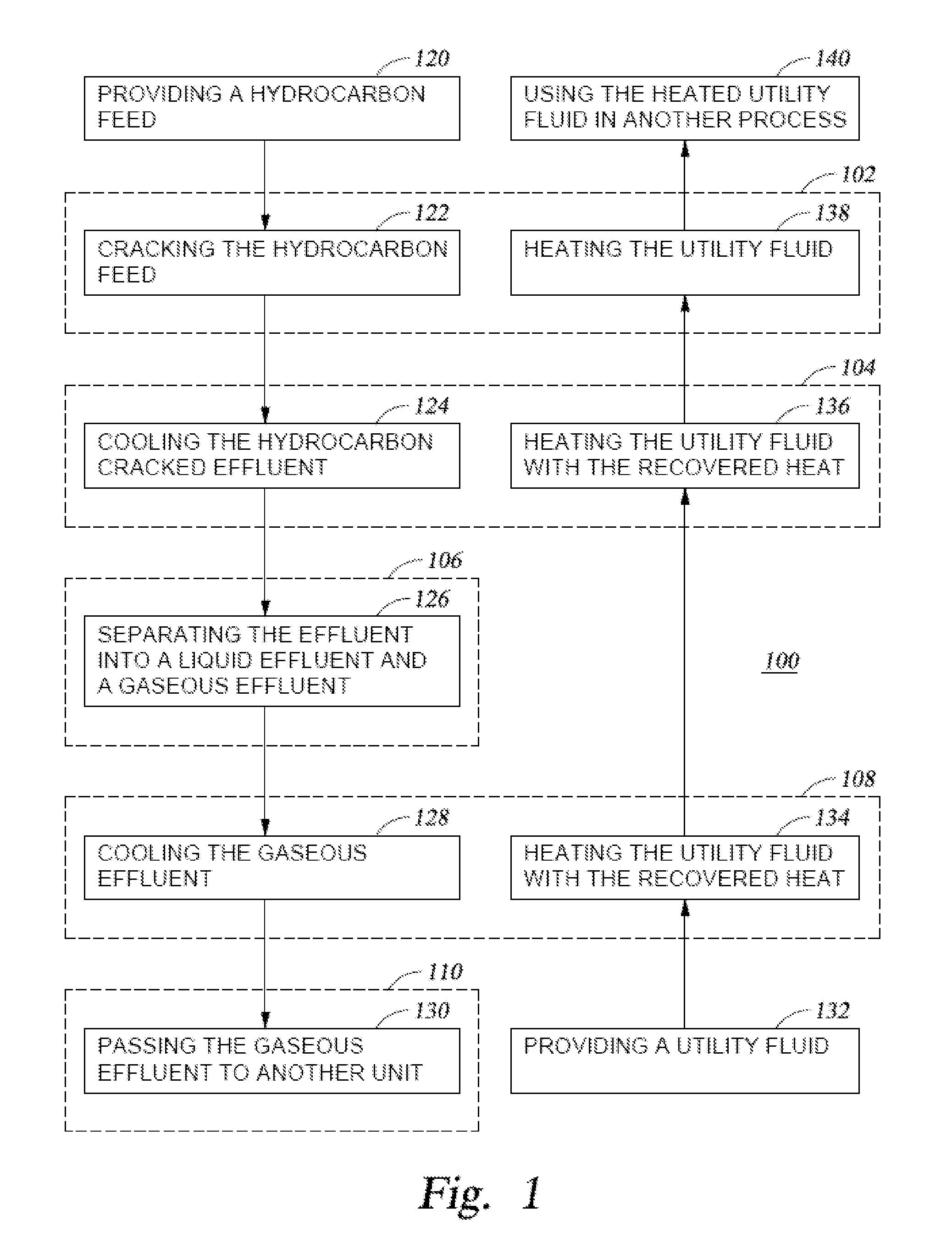

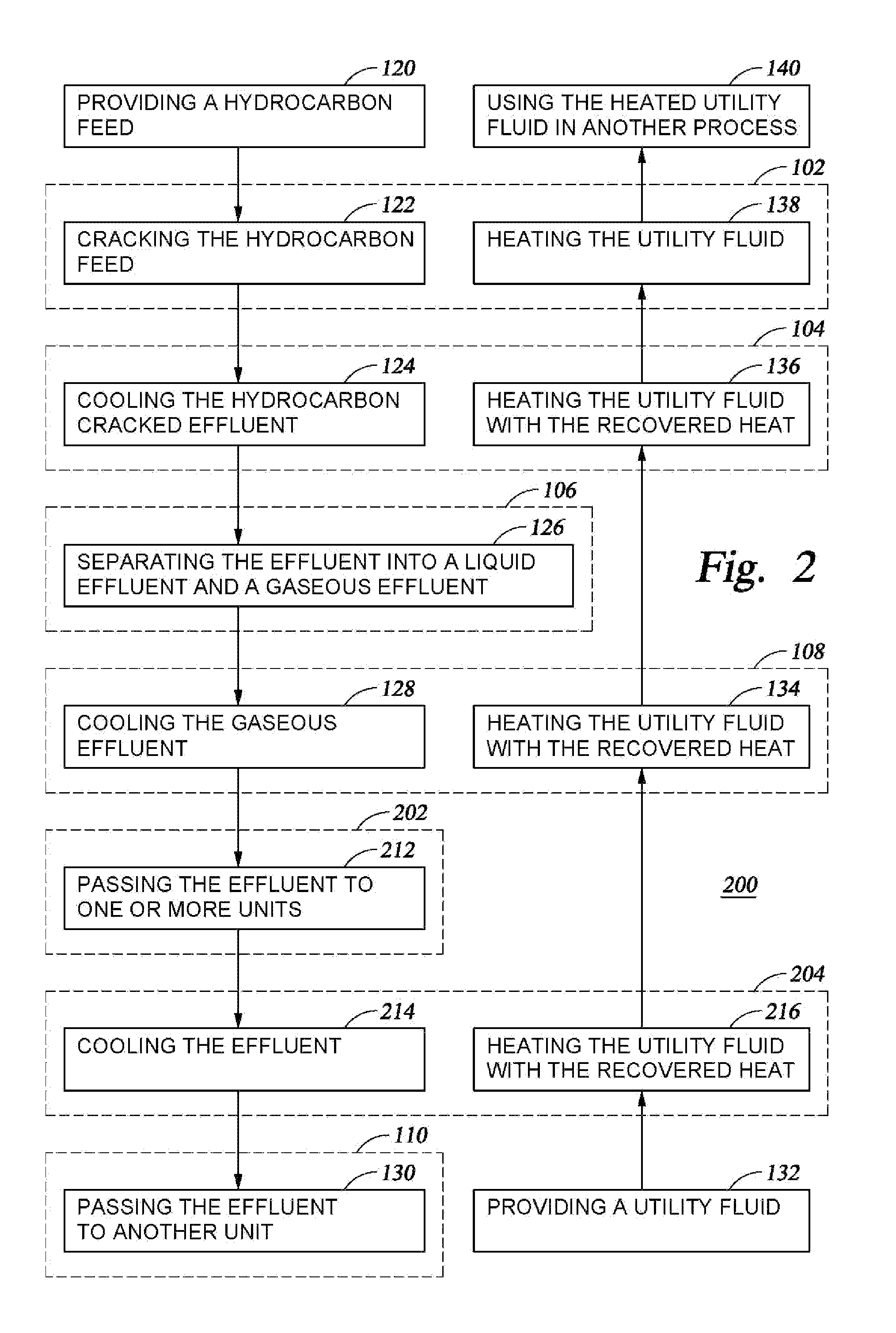

[0024]The present techniques provide an efficient arrangement to treat the effluent stream from a hydrocarbon pyrolysis unit, which may be referred to as a pyrolysis reactor or furnace, so as to remove and recover heat therefrom and to separate desired hydrocarbons. For instance, the present techniques may separate C5+ hydrocarbons, providing separate pyrolysis gasoline, gas oil, quench oil, and tar fractions, as well as the desired C2-C4 olefins in the effluent without utilizing primary fractionator pumparounds.

[0025]Typically, the effluent used in the one or more embodiments of the present techniques is produced by pyrolysis of a hydrocarbon feed boiling in a temperature range from about 40° C. to about 704° C. (about 104° F. to about 1300° F.), such as naphtha, tailed crudes or gas oil. For example, the effluent may be produced by pyrolysis of a hydrocarbon feed having a final boiling point above about 180° C. (about 356° F.), such as a feed heavier than naphtha. Such feeds inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| outlet temperature | aaaaa | aaaaa |

| pressures | aaaaa | aaaaa |

| pressures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com