Marine engine lubrication

a technology for marine engines and lubricating parts, applied in marine propulsion, vessel construction, propulsive elements, etc., can solve problems such as crankcase explosion, crack formation and propagation through the piston, and achieve the effect of improving asphaltene handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0101]The present invention is illustrated by but in no way limited to the following examples.

Components

[0102]The following components were used:

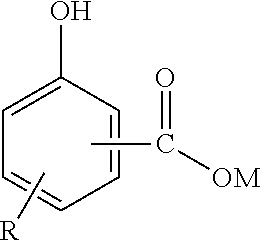

Component (A):

[0103](A1) a calcium salicylate detergent having a TBN of 350 (basicity index of two or greater; a degree of carbonation of 80% or greater)[0104](A2) a calcium salicylate detergent having a TBN of 225 (basicity index of two or greater; a degree of carbonation of less than 80%)[0105](A3) a calcium salicylate detergent having a TBN of 65 (basicity index of less than two; a degree of carbonation of less than 80%)

Component (B):

[0106](B1) oleic acid[0107](B2) polyisobutene succinic acid derived from a polyisobutene having a number average weight of 450[0108](B3) a polyisobutene succinic anhydride (“PIBSA”) derived from a polyisobutene of number average molecular weight 950 (72% ai)[0109](B4) polyisobutene succinic anhydride (“PIBSA”) derived from polyisobutene having a number average molecular weight of 450 (75% ai)[0110](B5) iso-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass % | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com