Solid state thermoelectric power converter

a thermoelectric power converter and solid-state technology, applied in the direction of crystal growth process, polycrystalline material growth, chemistry apparatus and processes, etc., to achieve the effect of increasing the surface area available for cooling and improving the efficiency of power conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

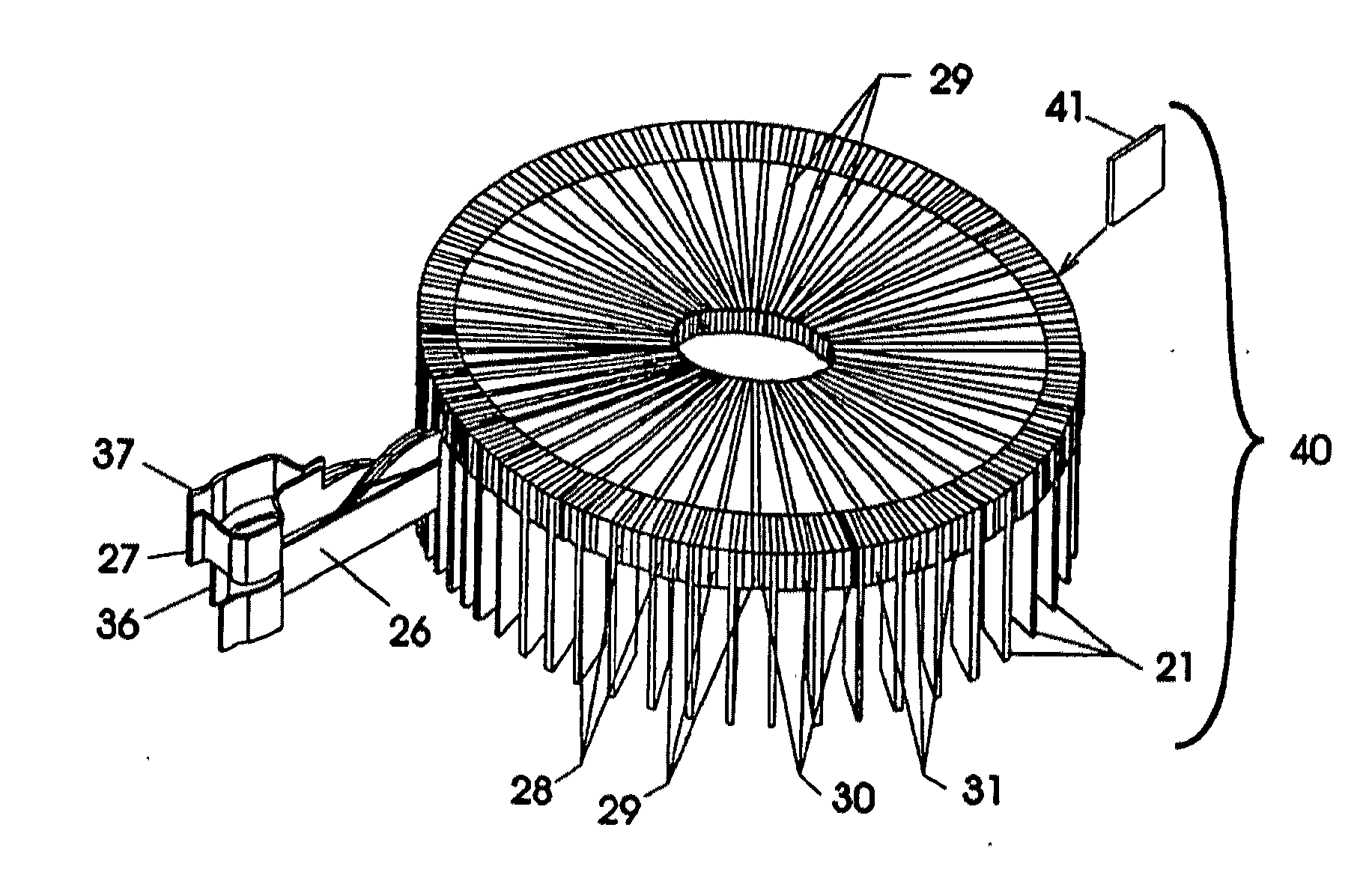

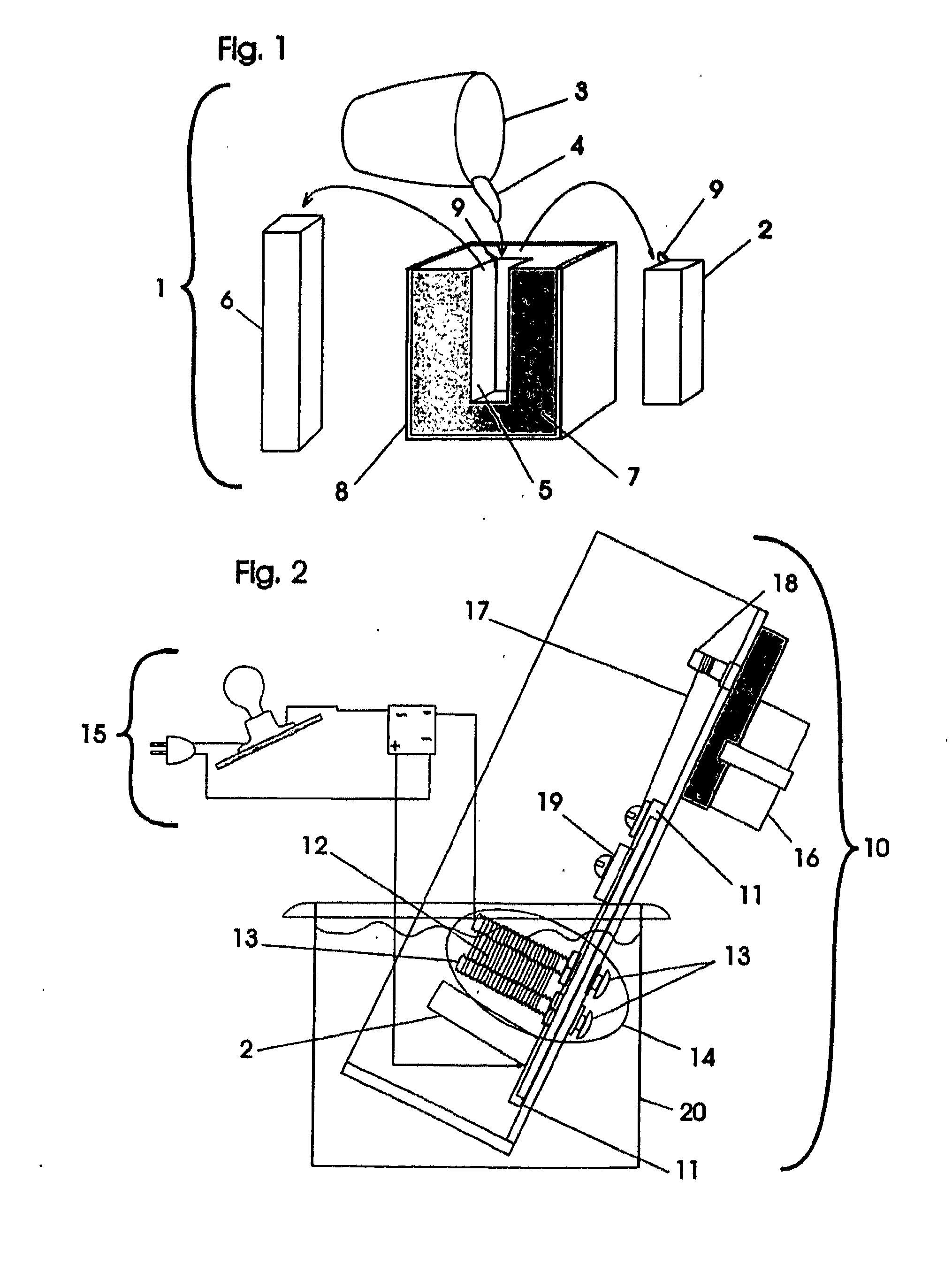

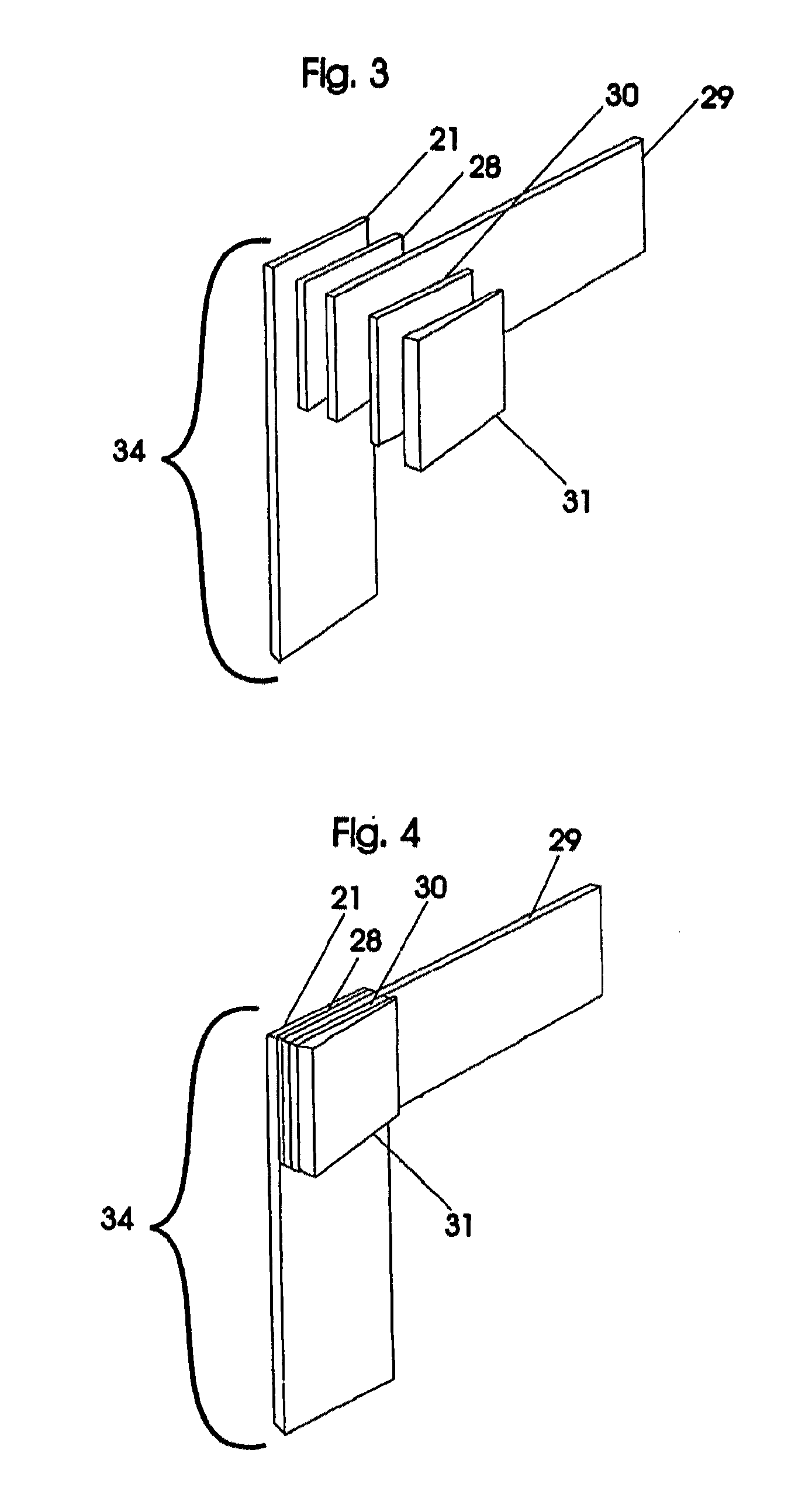

Image

Examples

example 1

Reduced Barriers n-Type Semiconductor Composition

[0130]

ElementRangePreferred AmountSelenium 5%-12%10%Bismuth40%-60%45%Telluriumremainder to 100%45%

This n-type selenium-bismuth-telluride-based semiconductor composition represents a formula [Bi2Te3]0.35 [Bi2Se3]0.65 approximating a ratio of one part dibismuth tritelluride and two parts dibismuthtriselenide. This product appears to be crystalline.

example 2

Reduced Barriers p-Type Semiconductor Composition

[0131]

ElementRangePreferred AmountAntimony28%-32%30%Bismuth 8%-12%10%Telluriumremainder to 100%60%

[0132]This p-type antimony-bismuth-telluride-based semiconductor composition represents a formula [Bi2Te3]0.35 [Sb2Te3]0.65 or about one part dibismuthtritelluride and 2 parts diantimonytritelluride. Diantimonytritelluride structural form is a glass. The structure of dibismuth-tetraantimony-nonatelluride as produced by the method described herein appears to be crystalline.

[0133]Copper and some other elements greatly degrade performance of these semiconductors; therefore high purity elements are needed. Each chemical element should be at least 99.9% pure and preferably 99.999% pure.

[0134]Semiconductors are protected from infiltration of copper atoms and components of solder by first coating the wafer edges with a non-conductive high temperature-melting ink, brand named “mark-tex” high temp 44 manufactured by DYKEM, preferably color coded p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| secondary voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com