Washing machine

a washing machine and washing machine technology, applied in the field of washing machines, can solve the problems of deteriorating the deterrent of surfactants, adversely affecting the washing performance, and unit washing machines coated with detergent residue and turning moldy, and achieve the effect of high selectivity for h+ ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first exemplary embodiment

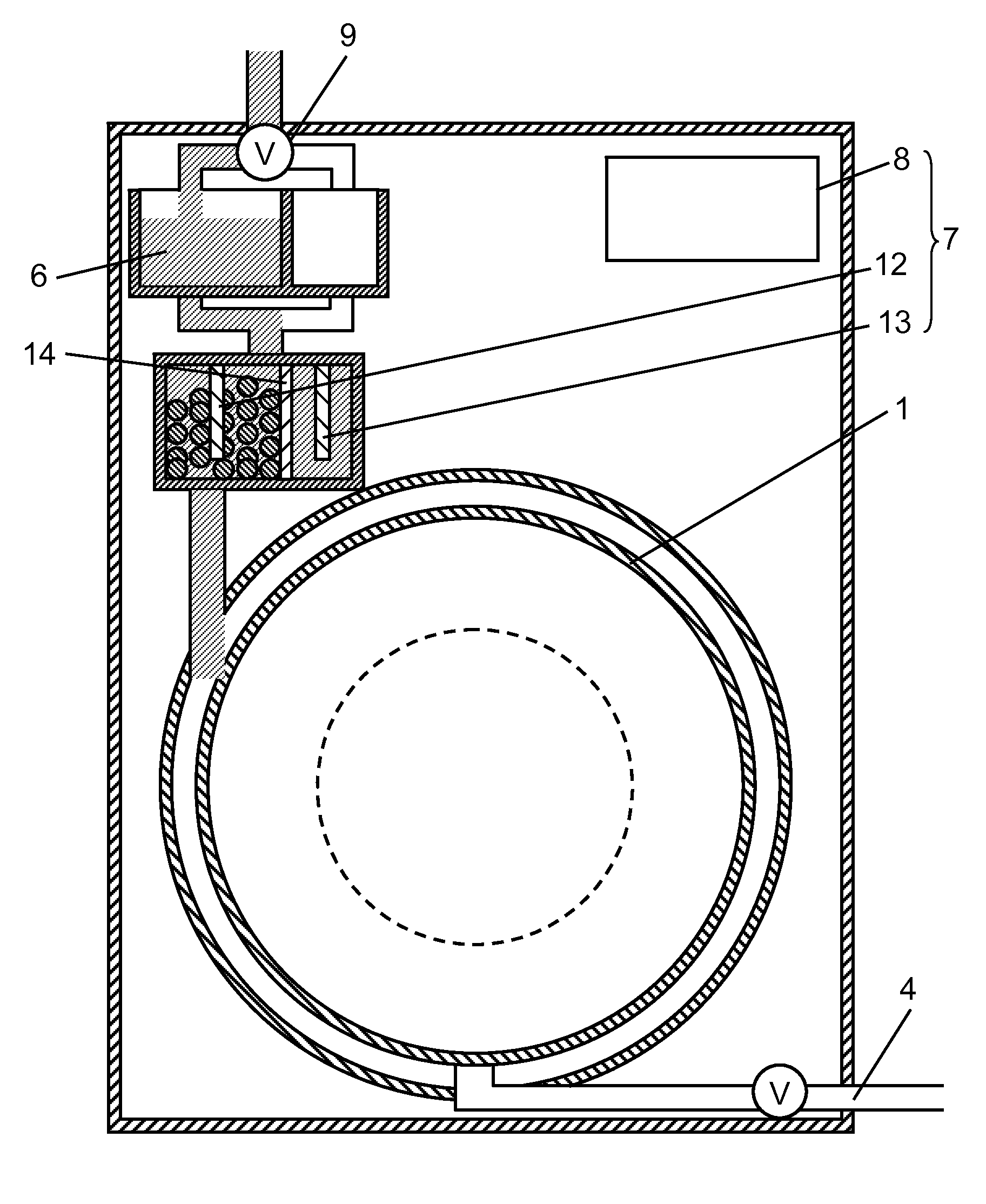

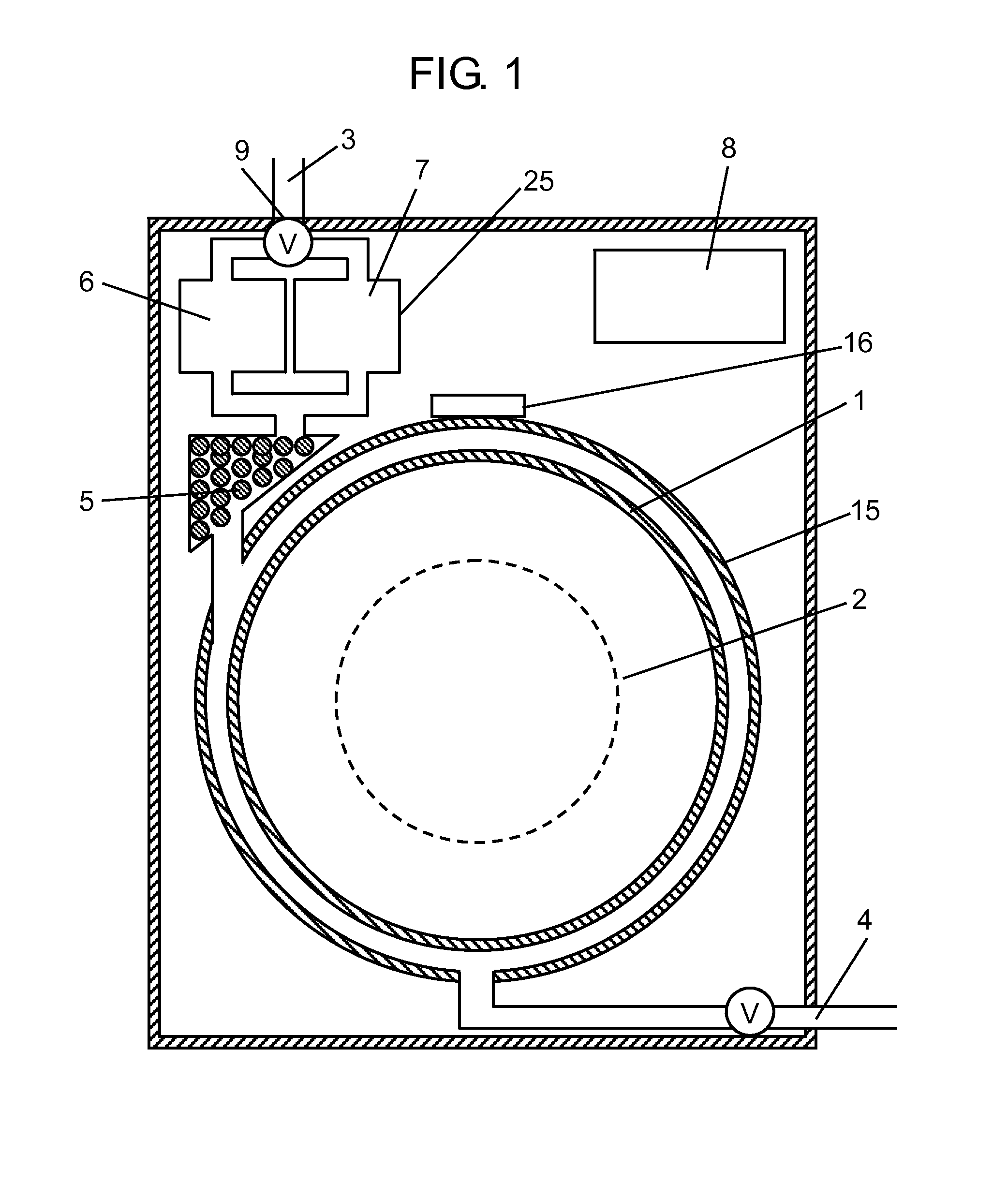

[0026]FIG. 1 is a configuration diagram of a washing machine according to a first exemplary embodiment of the present invention. The washing machine shown in FIG. 1 includes washing tub 1, water tub 15, drive unit 16, washing unit 2, feed-water unit 3, drain unit 4, water softening unit 5, detergent container (pH increasing unit) 6, pH decreasing unit 7, and control unit 8.

[0027]Washing tub 1 is rotatable and accommodates laundry. Washing unit 2 includes a motor, which stirs washing tub 1 and provides physical washing effect. Feed-water unit 3 feeds washing water into water tub 15 and washing tub 1. Drain unit 4 drains washing water from water tub 15 and washing tub 1. Water softening unit 5 is disposed between feed-water unit 3 and water tub 15 so as to soften the washing water fed by feed-water unit 3. Water softening unit 5 is filled with a weak acid cation exchange material having weak acidic cation exchange groups with a pH from 7.5 to 14 at point of zero charge. Detergent cont...

second exemplary embodiment

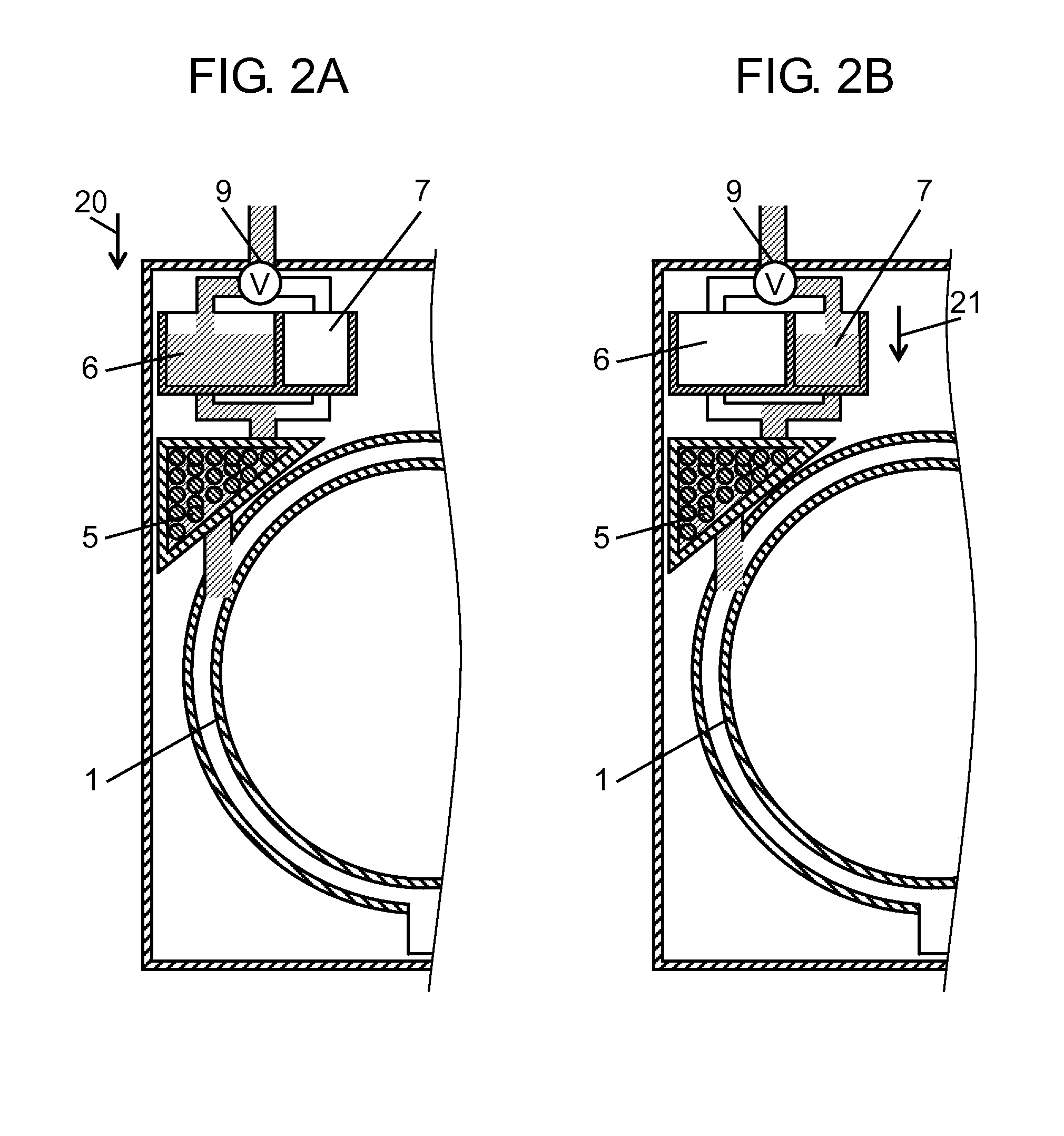

[0045]In a second exemplary embodiment, components identical to those in the first exemplary embodiment are denoted by the same reference numerals, and these components will not be described again in detail. The following description will be directed to their differences. FIGS. 3A and 3B show tap water being fed before a washing step and before a rinsing step, respectively, in a washing machine according to the second exemplary embodiment.

[0046]The washing machine of the second exemplary embodiment includes channel switching valve 10 between water softening unit 5 and washing tub 1. Valve 10 switches between the two channels: one guides water to washing tub 1, and the other drains the water.

[0047]As shown in FIG. 3A, water softening unit 5 performs water softening under alkaline conditions in the same manner as in the first exemplary embodiment. In this case, channel switching valve 10 allows softened washing water to flow in the direction of arrow 22 so as to be fed to washing tub ...

third exemplary embodiment

[0052]In a third exemplary embodiment, components identical to those in the first exemplary embodiment are denoted by the same reference numerals, and these components will not be described again in detail. The following description will be directed to their differences. FIG. 4 is a configuration diagram of a washing machine according to the third exemplary embodiment.

[0053]PH decreasing unit 7 used in the present third exemplary embodiment includes a pair of electrolysis electrodes and control unit 8 having a voltage application function. The electrolysis electrodes consist of anode 12 disposed surrounded by the weak acid cation exchange material, and cathode 13 disposed adjacent to anode 12 with isolation film 14 therebetween.

[0054]These electrolysis electrodes are applied with no voltage when washing water is fed. The weak acid cation exchange material generates negative charges on its surface due to the effect of alkaline detergent, and performs water softening function.

[0055]Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com