Device having reduced friction properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Sample 1

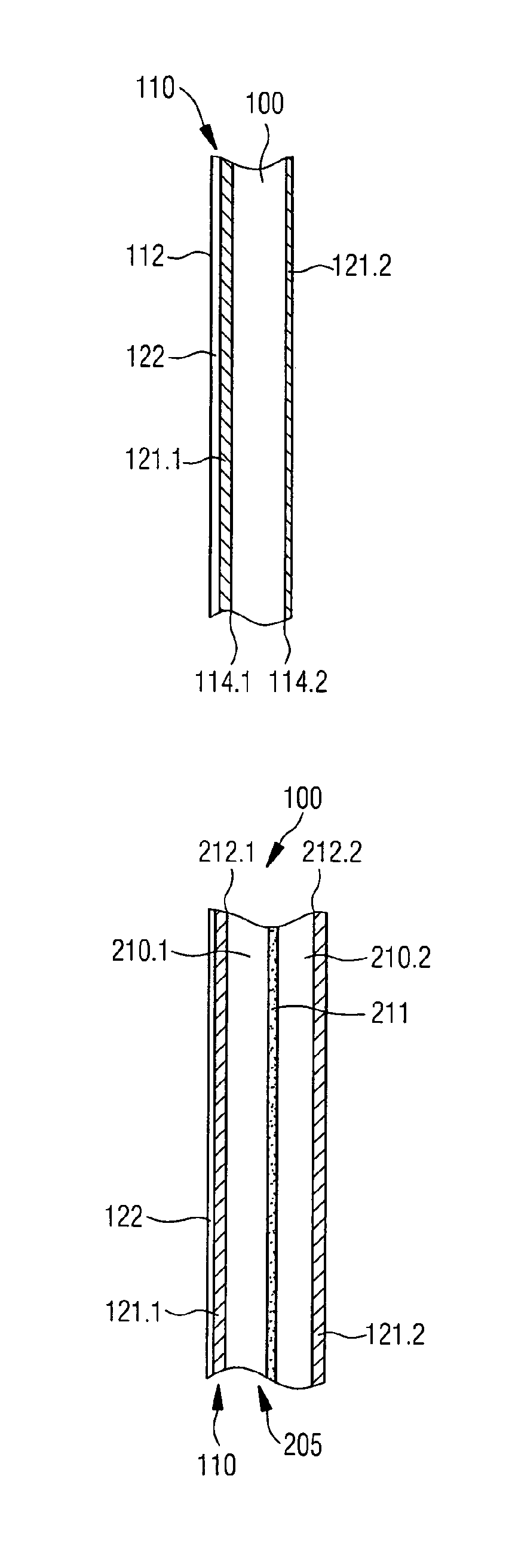

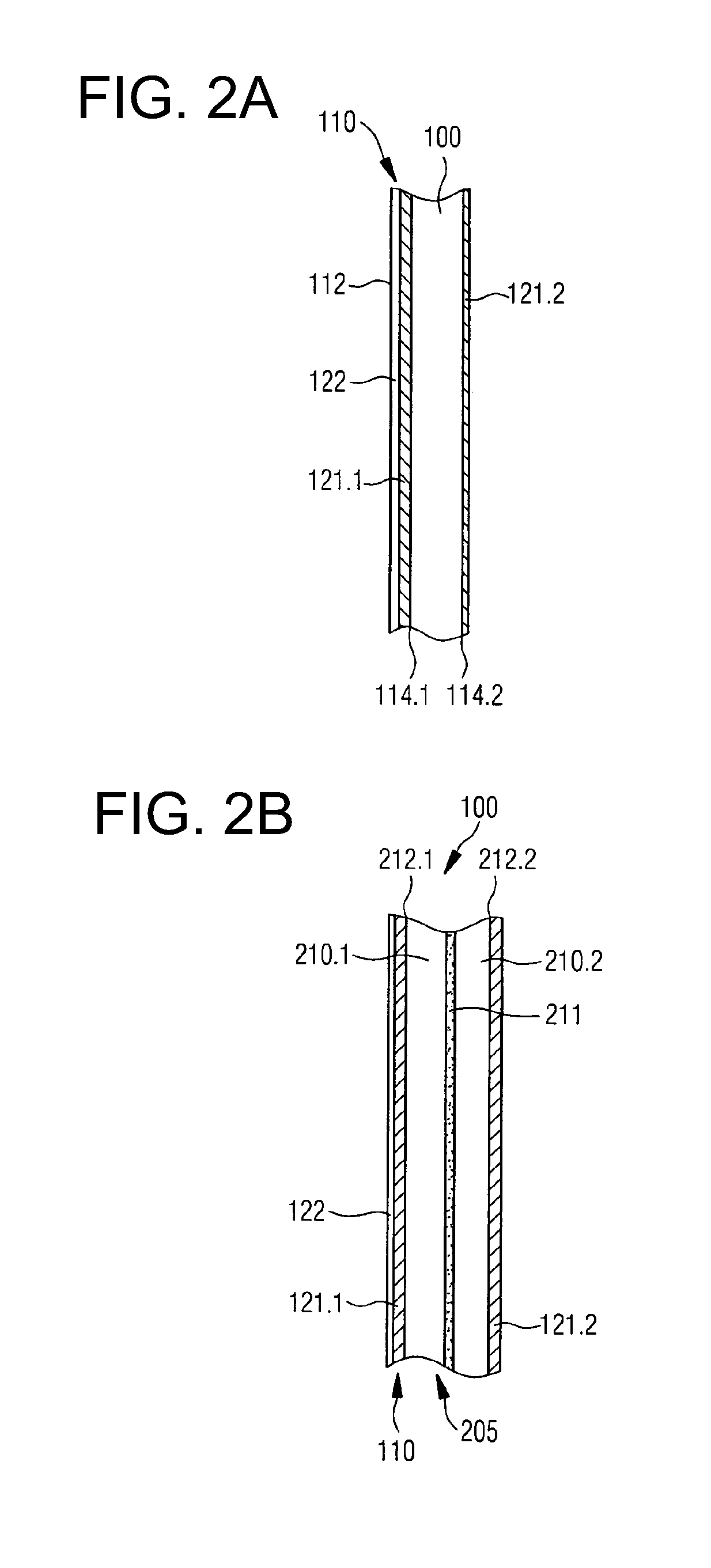

[0063]In the trial according to sample 1 the anti-reflection coating was produced according to the sol-gel method. The coating includes three individual layers respectively and possesses the following structure: Substrate+M+T+S.

[0064]The individual layer identified with T contains titanium dioxide (TiO2). The individual layer identified with S contains silicon dioxide (SiO2) and the individual layer identified with M is always drawn from S and T mixed solutions. The float glass substrate is carefully cleaned prior to coating. The dipping solutions are respectively applied in rooms which are air-conditioned to approximately 28° C. at a humidity of 5 to 10 grams per kilogram (g / kg), whereby the draw speeds for each individual layer M / T / S are approximately 275 / 330 / 228 millimeters per minute (mm / min). Drawing of each gel layer is followed by a curing process in air. The curing temperature and the curing time are approximately 180° C. / 20 min after production of the first gel laye...

example 2

Sample 2

[0067]The example-sample 2 is a one-sided anti-reflection coating which is applied as follows in the sputtering process: The coating is deposited in an inline unit in a mid-frequency (MF) sputtering process through magnetron sputtering, whereby the substrate is positioned on a so-called carrier and is transported on same through the sputtering unit. The application method is as follows:[0068]a) Inside the coating unit the substrate is first “heated to approximately 150° C. for dewatering of the surface”. Then an anti-reflection system (for example including four layers) is produced as follows:[0069]b) Sputtering of a high refractive substrate at a feed rate of approximately 1.7 meters per minute (m / min), whereby the carrier oscillates in front of the sputtering source and while the layer of 30 nm thickness is deposited. The production of the layer occurs through addition of argon and reactive gas, by regulating the reactive gas to plasma impedance. The process pressure is de...

example 3

Sample 3

[0076]A layer according to sample 1 is pre-cleaned in a washing machine and pre-treated with a neutralizer so that the coating is fat free. The thus cleaned surface is sprayed with the product ClearShield which is offered commercially for example by Fa. Bohle in Haan (Germany) and which represents a typical fluoro-polymer solution for ETC (Easy To Clean) applications. The surface sprayed with ClearShield is left to react at room temperature for approximately 10 to 15 minutes. The coated surface is then washed and dried. Through the coating with an ETC (easy to clean) ClearShield layer the contact angle can be substantially improved compared to untreated samples, as in sample 1 or 2. However, an increase of the contact angle by 23 or respectively 46 degrees in sample 1 or respectively sample 2 to 78 degrees in sample 3 does not mean that the respective coefficient of friction is achieved and that therefore a finger or pen can glide more easily over the surface or that a dry c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com