Hydrogen and Nitrogen Recovery from Ammonia Purge Gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

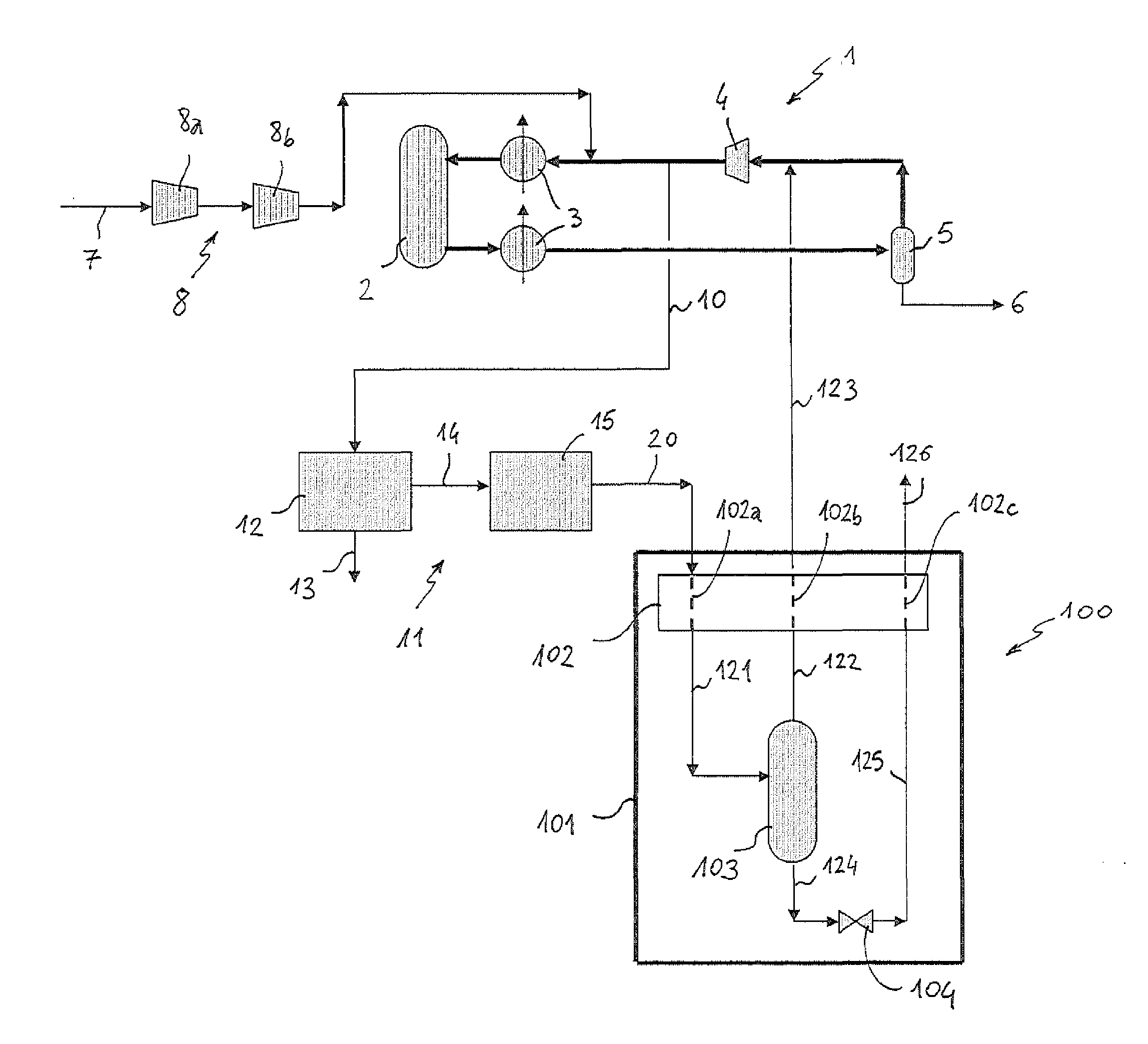

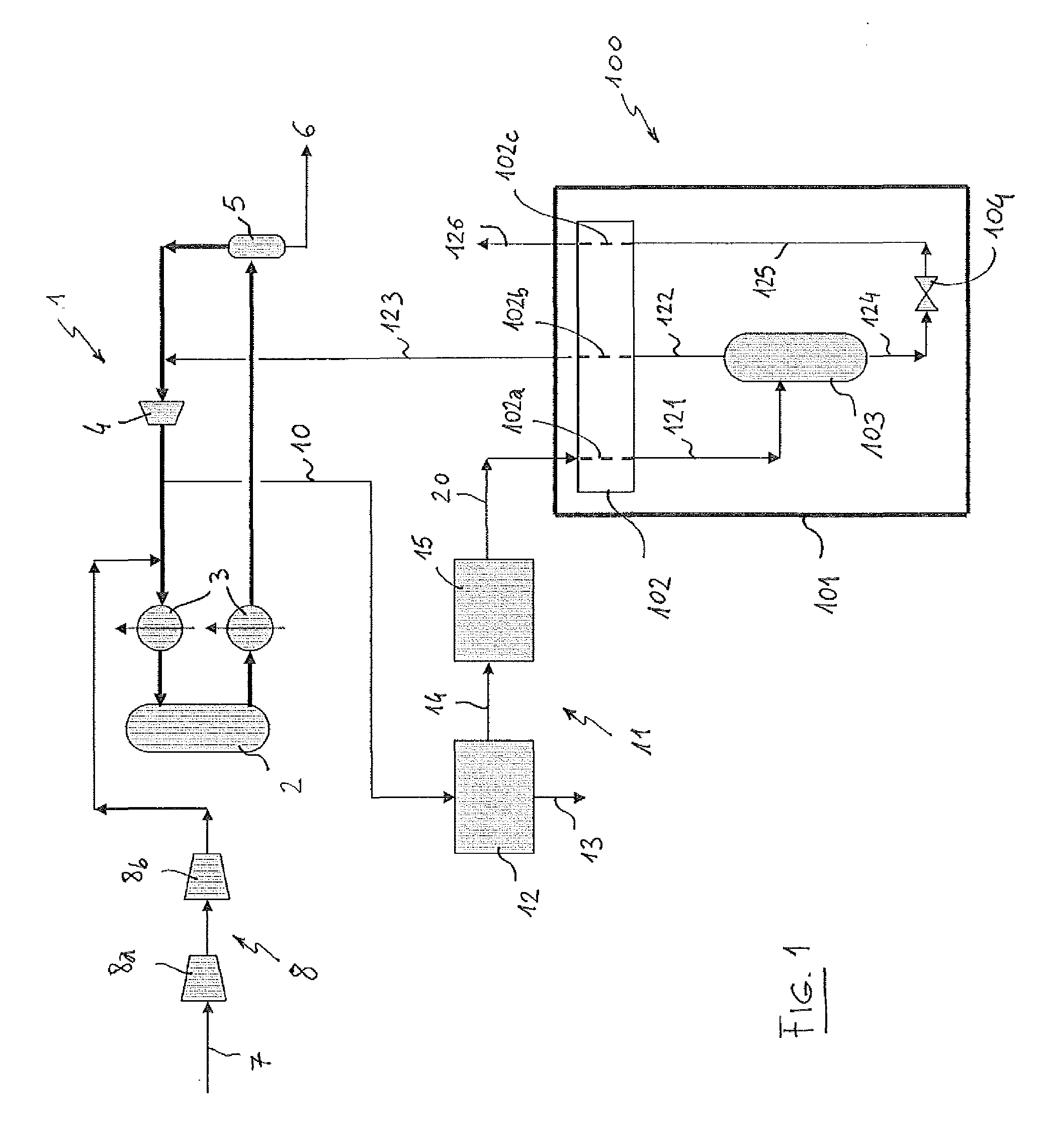

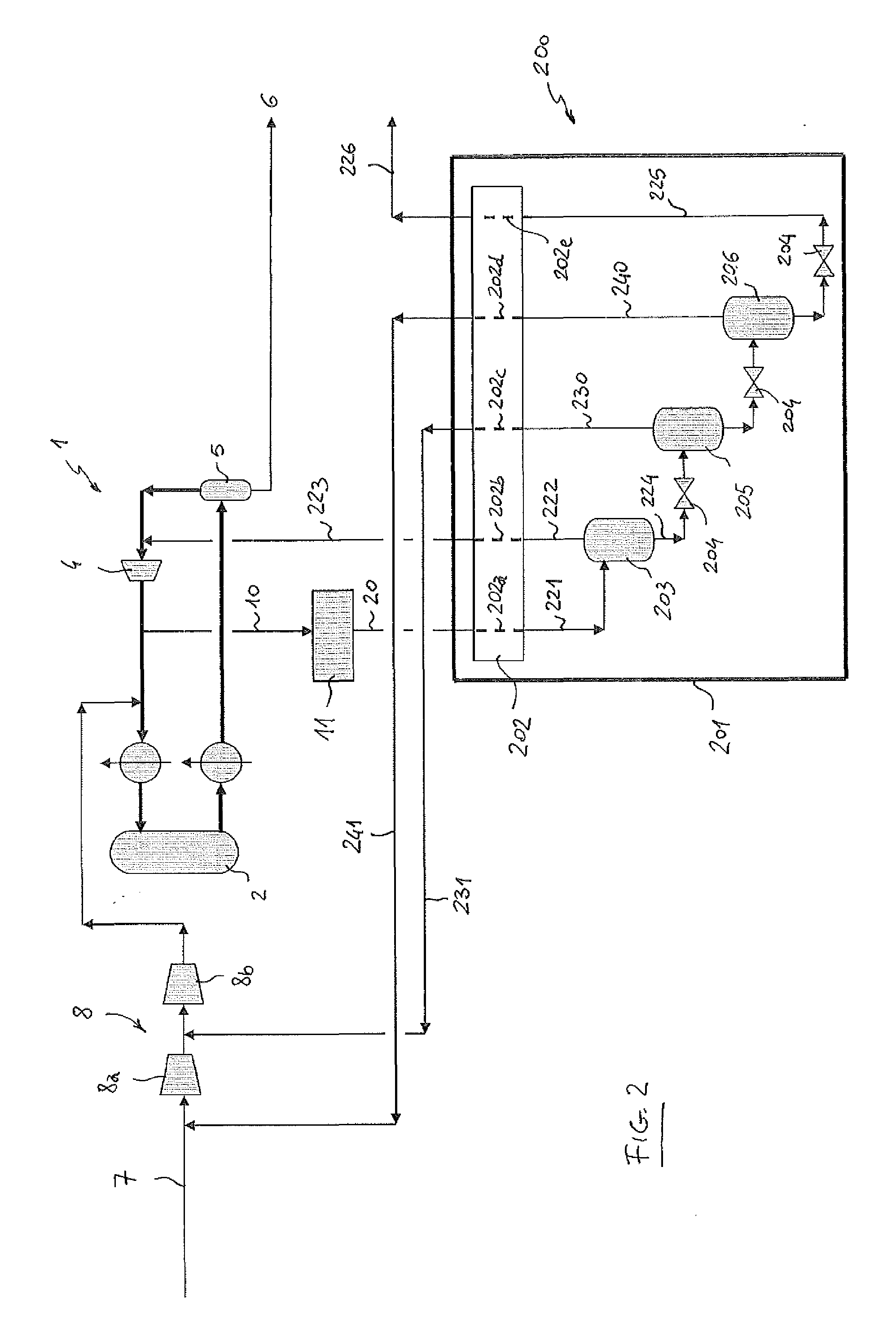

[0051]Referring to the first embodiment of FIG. 1, a plant for synthesis of ammonia from a make up gas containing hydrogen and nitrogen comprises a synthesis loop 1 operating at a loop pressure, which is usually a high pressure such as 150 bar or more. The loop 1 comprises basically a converter 2, heat exchangers 3, a circulator 4 and a separator 5, delivering the ammonia product 6. The loop is fed with make-up gas 7 by means of a main compression unit 8.

[0052]The make-up gas 7 is produced in a front-end section of the plant, for example by reforming a suitable hydrocarbon source, at a pressure significantly lower than the loop pressure of loop 1. The main compression unit 8 raises the pressure of the make up gas delivered by said front-end section to the pressure level of the loop. The compression unit 8 is normally a multi-stage unit, in the figure two stages 8a and 8b are shown. The circulator 4 overcomes the pressure losses along the loop 1 itself, including the pressure losses ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com