Medical mask with a functional material

a functional material and medical mask technology, applied in the field of medical masks with functional materials, can solve the problems of not being easy to add surficial decorations and functions, and achieve the effect of improving function and reducing discomfor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Polylactic Acid+Catechin Polyphenol+NaCl

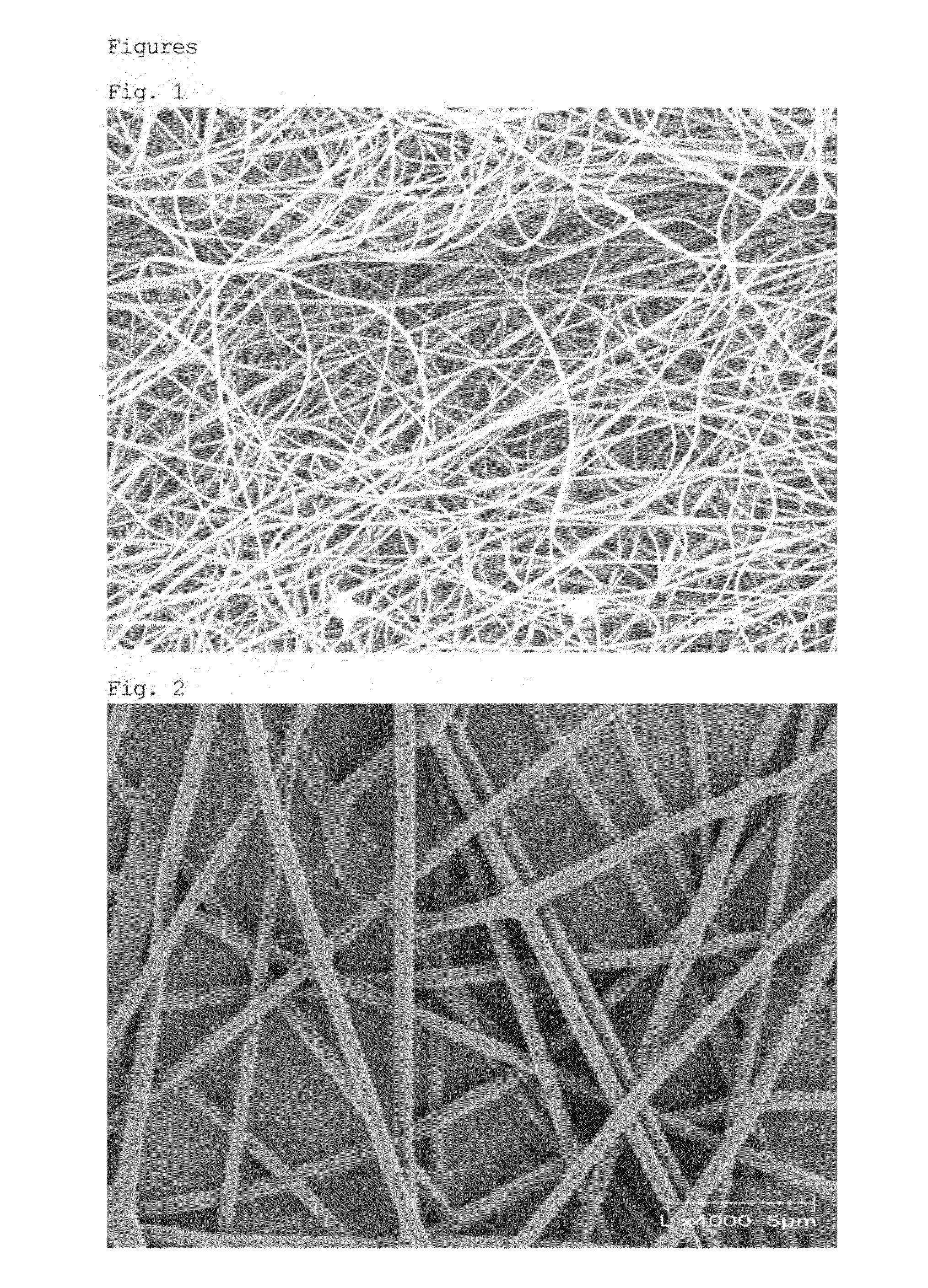

[0100]A polylactic acid (Mitsui Chemicals, Inc.) was used as a base polymer, and a catechin polyphenol (Sunphenon BG-3, Taiyo Kagaku Co., Ltd., hereinafter called “catechin (Sunphenon BG-3)”) was used as a functional substance to make a non-woven fabric.

[0101]10 g of polylactic acid and 90 g of dichloromethane were mixed and a polylactic acid resin was dissolved at normal temperature (about 25° C.) to prepare a biodegradable polyester-containing solution (polymer-containing solution). In addition, ethanol was added to the catechin (Sunphenon BG-3) and dissolved to prepare a 20 wt % polyphenol compound-containing solution (functional substance-containing solution), in which 0.01 wt % of NaCl was further dissolved. The two solutions, 7.5 g of biodegradable polyester-containing solution and 2.5 g of polyphenol compound-containing solution were mixed to obtain a colorless and transparent mixed solution. This mixed solution (transparent solution co...

example 2

Polylactic Acid+Catechin Polyphenol

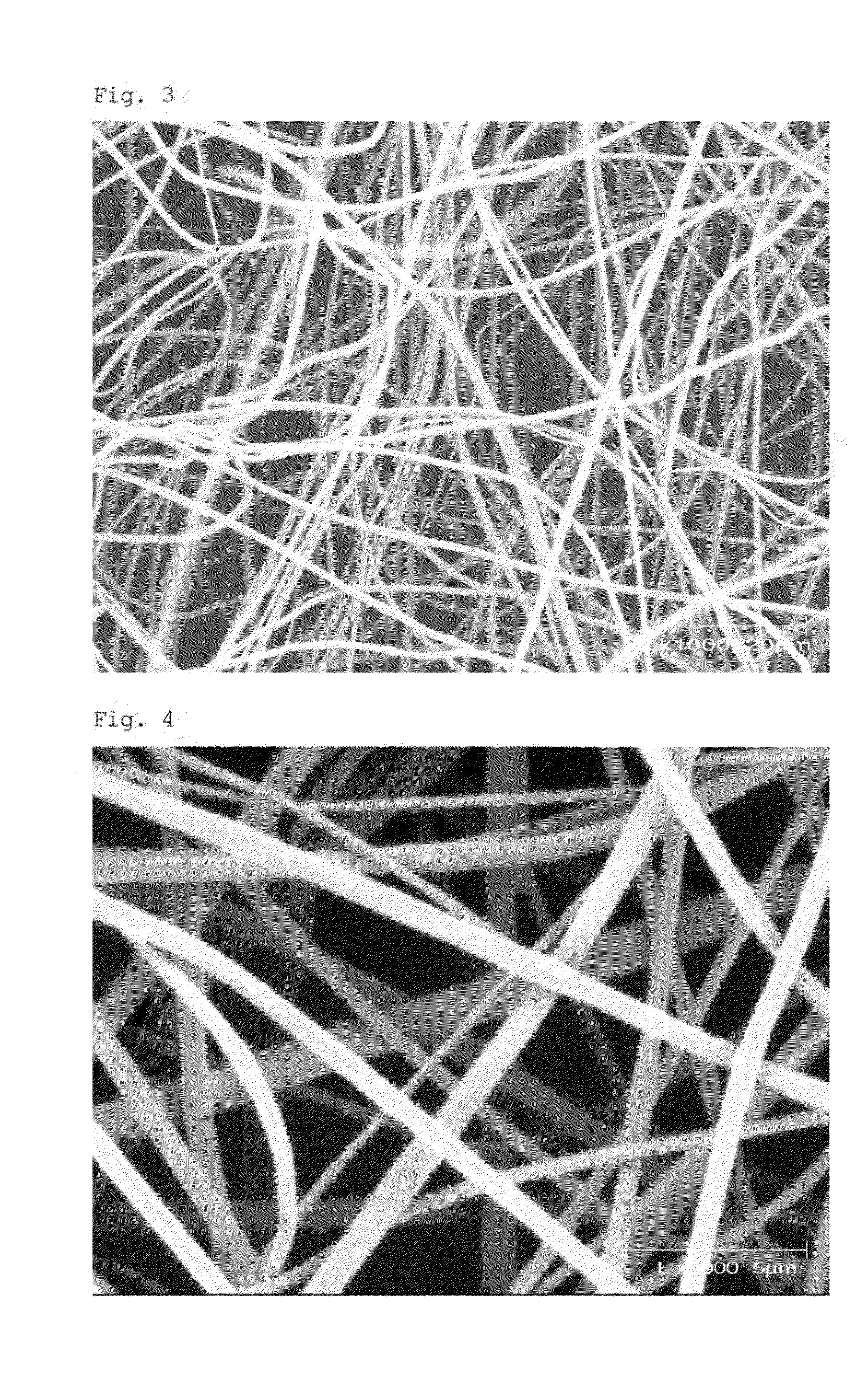

[0103]A polylactic acid (Mitsui Chemicals, Inc.) was used as a base polymer, and a catechin polyphenol (Sunphenon EGCg, Taiyo Kagaku Co., Ltd., hereinafter called “catechin (Sunphenon EGCg)”) was used as a functional substance to make a non-woven fabric.

[0104]10 g of polylactic acid and 90 g of dichloromethane were mixed and a polylactic acid resin was dissolved at normal temperature (about 25° C.) to prepare a biodegradable polyester-containing solution (polymer-containing solution). In addition, dimethylformamide was added to the catechin (Sunphenon EGCg) and dissolved to prepare a 20 wt % polyphenol compound-containing solution (functional substance-containing solution). Of the two solutions, 7.5 g of biodegradable polyester-containing solution and 2.5 g of polyphenol compound-containing solution were mixed to obtain a transparent mixed solution. This mixed solution (transparent solution containing the polylactic acid and catechin EGCg) was fill...

example 3

Polylactic Acid+Persimmon Tannin Polyphenol

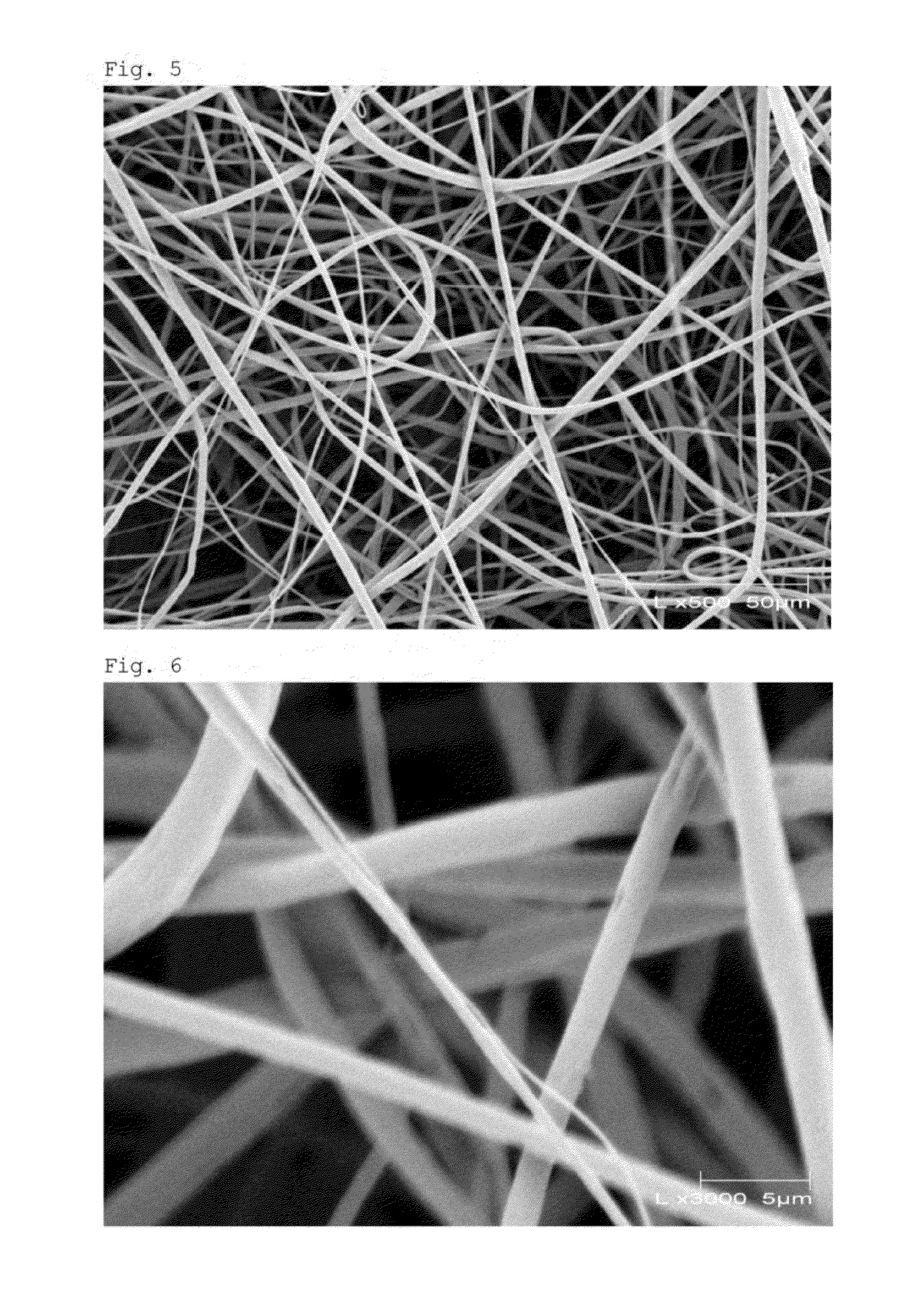

[0106]A polylactic acid (Mitsui Chemicals, Inc.) was used as a base polymer, and a persimmon tannin polyphenol (odorless persimmon tannin: Osugi Co., ltd.) was used as a functional substance to make a non-woven fabric.

[0107]10 g of polylactic acid and 90 g of dichloromethane were mixed and a polylactic acid resin was dissolved at normal temperature (about 25° C.) to prepare a biodegradable polyester-containing solution (polymer-containing solution). In addition, dimethylformamide was added to the persimmon tannin polyphenol and dissolved to prepare a solution containing 20 wt % of polyphenol compound (functional substance-containing solution). Of the two solutions, 7.5 g of biodegradable polyester-containing solution and 2.5 g of polyphenol compound-containing solution were mixed to obtain a transparent mixed solution. This mixed solution (transparent solution containing the polylactic acid and persimmon tannin polyphenol) was filled into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Magnetic field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com