Refrigerant repelling surfaces

a technology of refrigerant and surface, which is applied in the field of refrigerant repelling surfaces, can solve the problems of increasing the contact angle of liquid droplets on the surface when the atmosphere is substantially vaporized refrigerant, and many conventional systems suffer from the limitation of air present in the atmosphere of heat transfer systems, so as to increase the contact angle of liquid droplets on the surface, increase condensation rate, and increase the effect of heat transfer coefficien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Surface Tension and Contact Angle Calculations

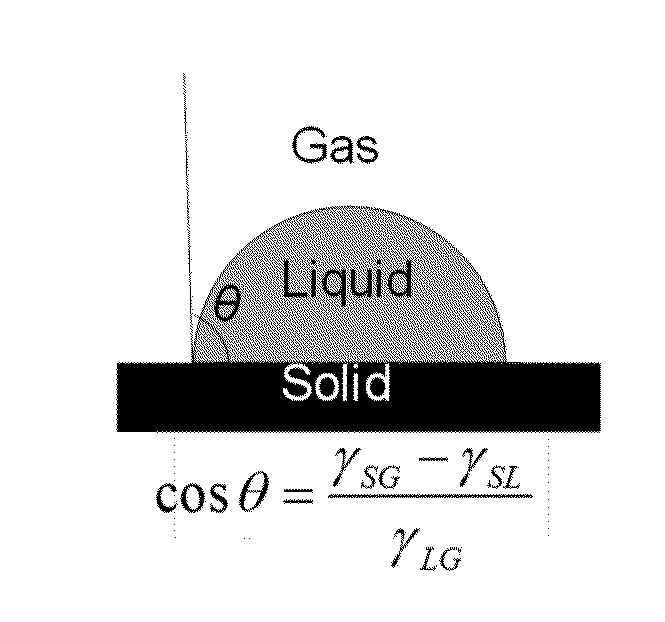

[0097]Equations 1 and 2 give relationships between the flat surface contact angle and the relevant surface free energies and the variation in the surface free energy with temperature.

Cos(θC)=γSG-γSLγLV(Equation1)γ(T)=γ(T0)+Tcγ*(ΔT)(Equation2)

[0098]Where θc: Flat surface contact angle, γLV: Surface tension of water, γSG: Surface free energy (SFE) of surface (e.g. PTFR), γSL: SFE between surface and water, γ(T0): Value of γ at temperature T0., TCγ: Temperature coefficient of the substance., ΔT: (T0−T).

[0099]FIG. 1a illustrates the contact angle on a flat surface; in FIG. 1a θ is equivalent to θc in equation 1.

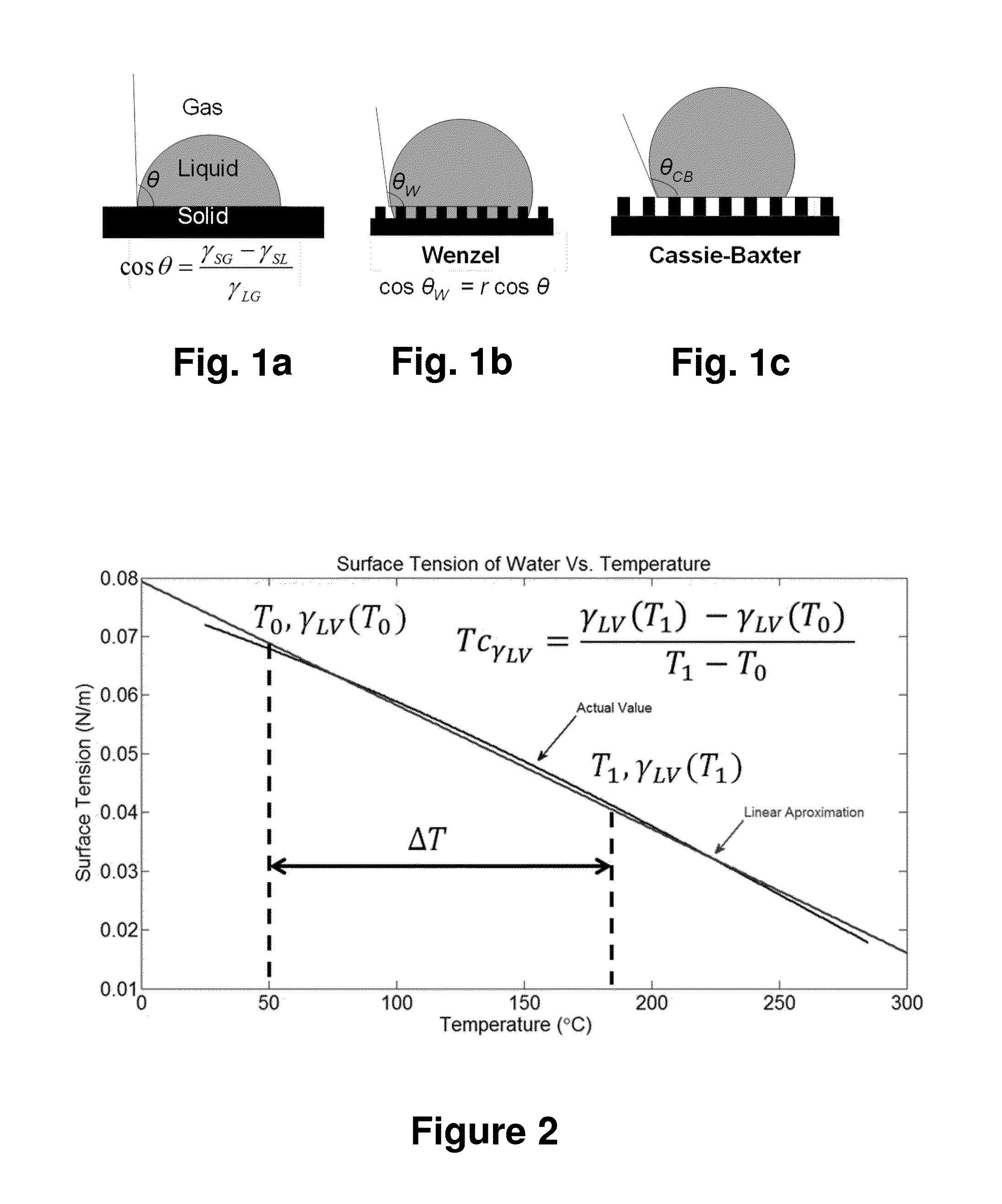

[0100]FIG. 2 shows water surface tension as a function of temperature.

Cos(θint)=γSG(Tint)-γSL(Tint)γLG(Tint)(Equation3)Cos(θcrit)=γSG(Tcrit)-γSL(Tcrit)γLG(Tcrit)(Equation4)TcγSL=γSL(Tcrit)-γLV(Tint)Tcrit-Tint(Equation5)

[0101]Where γSLcrit: Critical surface tension. Defined as Cos(θc)=1 @ γLV (Tcrit)=γcrit, Tcrit: Temperature where γLV...

example 2

Measurements for Water and Oleic Acid

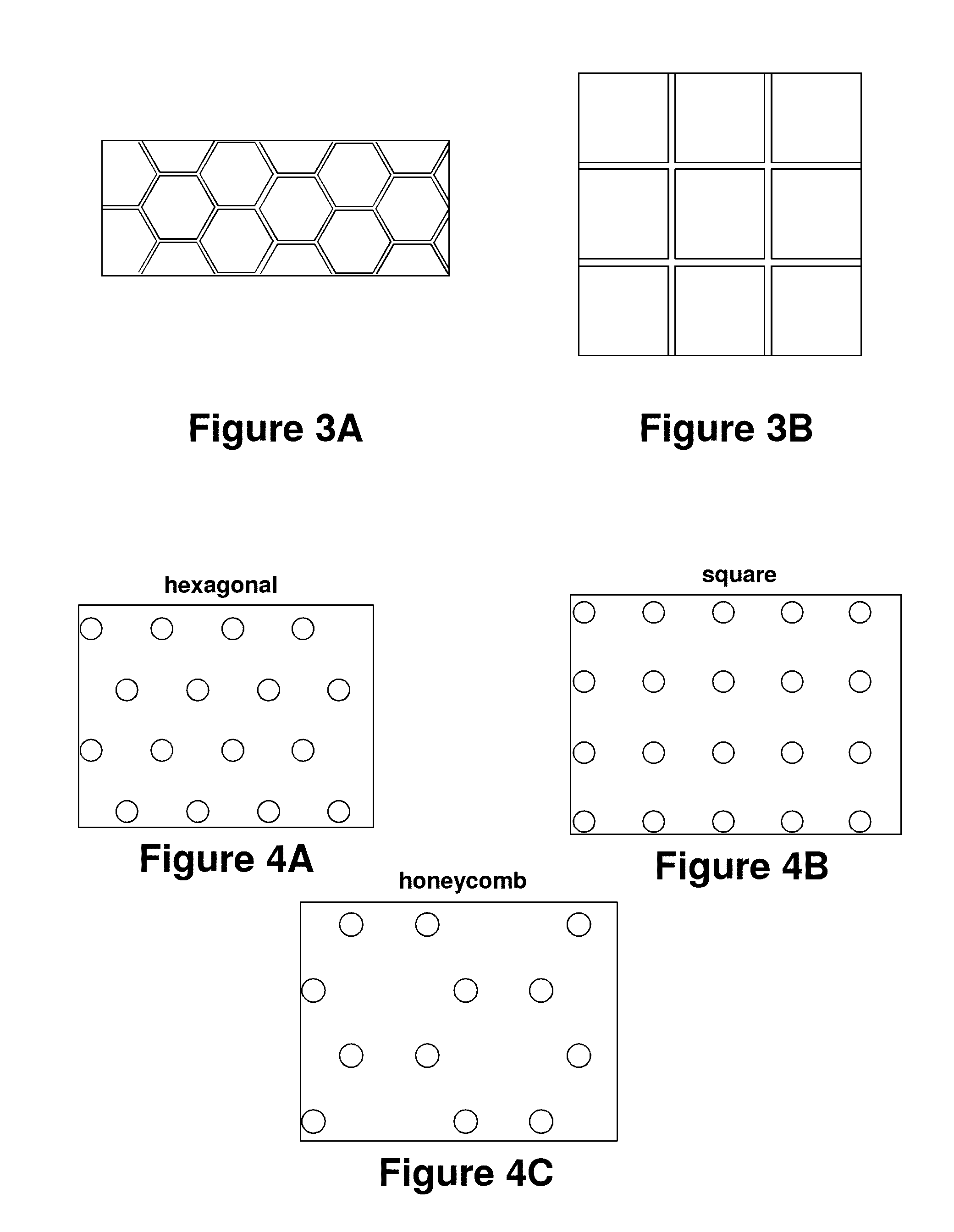

[0103]FIGS. 3A-B and 4A-C schematically illustrate some of the waffle and pillar surface textures fabricated for testing. FIG. 3 is a schematic top view of a hexagonal waffle structure (FIG. 3A) and a grid-like waffle structure (FIG. 3B). FIG. 4 is a schematic top view of different configurations of pillar elements: hexagonal arrangement (FIG. 4A), square arrangement (FIG. 4B), and honeycomb arrangement (FIG. 4C).

[0104]Tables 3 and 4 respectively provide additional information about waffle and pillar surface textures. In Table 2, h is element height, p is pitch and w is width of square or hexagonal depression. In Table 4, A is elements per area p2, d is diameter of the pillar, p is pitch, and h is element height.

TABLE 3Square Wafflesh (μm)p(μm)w (μm)32220Hexagonal Wafflesh (μm)p(μm)w (μm)31210

TABLE 4Square PillarsAd (μm)h (μm) p (μm)15050100Hexagonal PillarsAd (μm)h (μm) p (μm)1.5750300100

[0105]FIG. 5 shows an experimental setup used for contact ...

example 3

Measurements for HC-200

[0129]The contact angle of halocarbon oil HC-200 was measured on smooth and square waffle patterns. The experimental methods were the same as above, with only the liquid type being different. HC-200 is a liquid polymer oil with the chemical name chlorotrifluoroethylene. HC-200 has a surface tension about 0.025 N / m, which is lower than the surface tension for oleic acid. Table 9 shows the results, where the square waffle patterns are oleophobic, while a smooth surface of the same material is oleophillic. In Table 9, w is feature width, p is microstructure period, and d is feature depth.

TABLE 9wpdOilPatternLiquidμmμmμmCA°SmoothHC 200——— 40Square WafflesHC 20020220.3122

[0130]FIG. 27 shows images of halocarbon 200 oil on ZnO particle coated slides; these images illustrate the change in contact angle over 20 seconds. Image taken at 22° C. and 100. 3 kPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com