Process for the preparation of graphene

a graphene and graphene technology, applied in the field of graphene preparation processes, can solve the problems of affecting the quality of graphene produced by chemical exfoliation methods, affecting the structure of graphene bands, and residual surface species

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0054]Synthesis

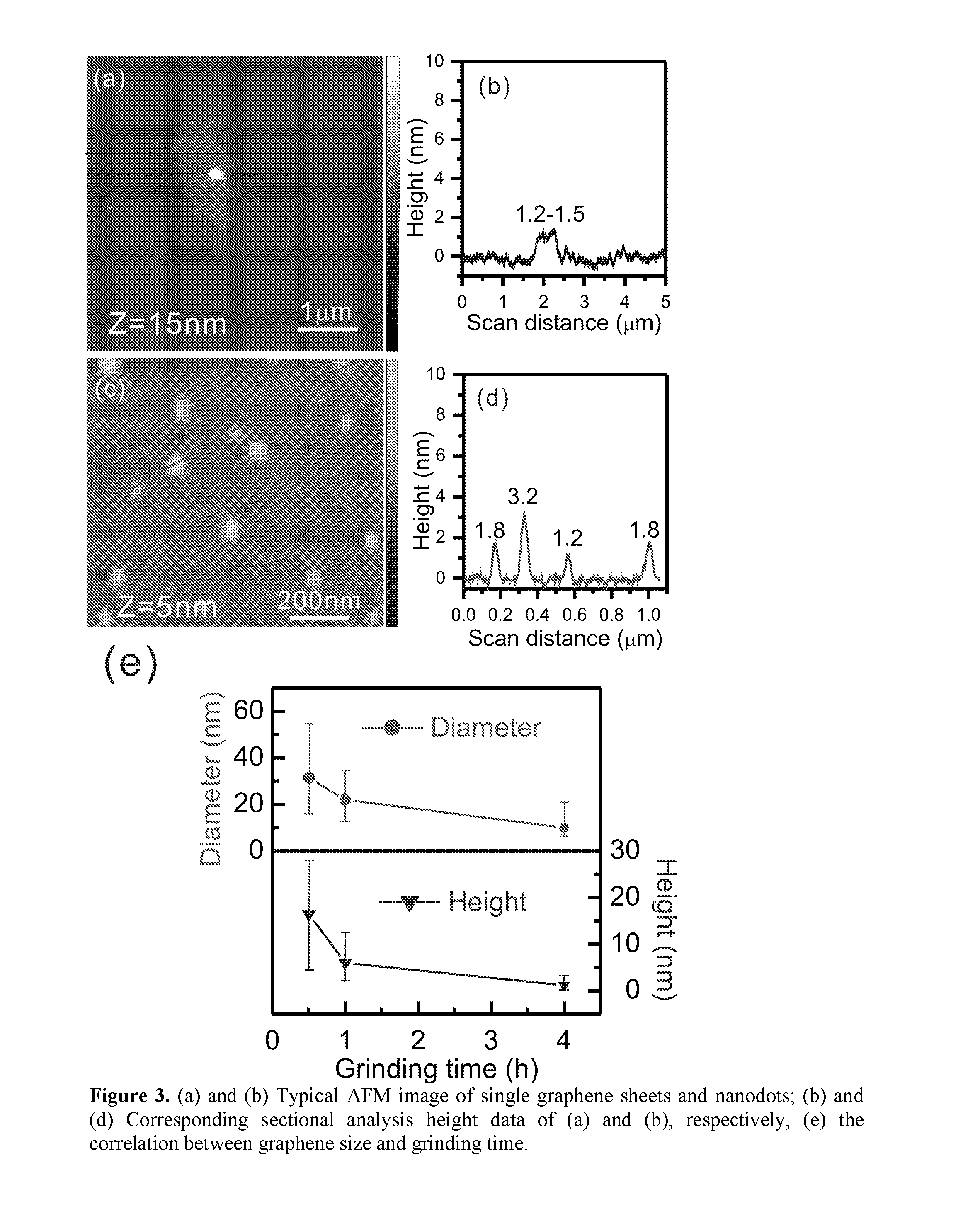

[0055]Graphite powders of 50 mg (99.0% purity, from Sigma-Aldrich) with a size less than 20 μm (typically 50 mg) were mixed and ground with 0.1-0.5 mL ionic liquid (1-Butyl-3-methylimidazolium hexafluorophosphate, BMIMPF6, from Sigma-Aldrich) for 0.5-4 hrs. Then the mixtures were added into a solution of 15 mL N,N-dimethylformamide (DMF) and 15 mL acetone and centrifugated in the speed of 3000 rpm for 30 min in order to remove the ionic liquid. After repeating this washing procedure for three times, the resulting sediment was diluted in 1 L DMF (see FIG. 1). After one-day sedimentation, the large / thick graphitic flakes completely precipitated on the bottom of the bottle. The supernatant was dried and then the yield was calculated as 20 wt %, which is much larger than that of other methods reported, such as by Coleman et al. in Nature Nanotechnology, 2008, 3, 563-568. The supernatant was collected and centrifugated to get the dense suspension, with which the graphene s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time period | aaaaa | aaaaa |

| time period | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com