Camouflage fabric having near infrared ray reflectance adjusting characteristics

a technology of near infrared ray reflectance and camouflage fabric, which is applied in the direction of protective fabrics, lighting and heating apparatus, instruments, etc., can solve the problems of imposing a negative effect on the visible tone, the method is limited in achieving appropriate visible and near infrared ray camouflage, and the enemy is difficult to detect the existence of such targets, etc., to achieve effective camouflage effect, improve concealment, and improve durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

manufacturing example 1 and manufacturing example 2

[0062]An aqueous silane coupling agent of about 1,000 mg / L which is an equimolar reaction product with imidazole and 3-mercaptopropyltrimethoxysilane was prepared as a preprocessing agent.

[0063]About 30 denier nylon filament yarn of about 50 Kg was dipped in water bath of about 200 Kg containing the preprocessing agent solution at a temperature of about 55° C. for about 60 minutes, and then non-reaction products was washed out with sodium hydroxide solution of about 1 wt %. Thereafter, the nylon filament yarn was dried at an atmospheric temperature of about 80° C. for about one hour.

[0064]Thereafter, the nylon filament yarn was cooled to a room temperature, and then was dyed with metal sulfide nanoparticles composition including copper sulfide or copper sulfide nanoparticles including compositions of Table 9 as postprocessing agent at a temperature of about 55° C. for about 120 minutes to form a nylon conductive yarn containing nanoparticles including copper sulfide or copper sulfid...

manufacturing example 3

[0067]The polyamide (nylon) conductive yarn manufactured in in which metal sulfide nanoparticles including copper sulfide with a total of metal content of about 2.84 wt % having about 30 denier, i.e., resistivity of about 2×10-2 Ωcm are coordinate-bonded and a TC blending yarn of about 60% polyester and about 265.5 denier and a TC blended yarn of about 265.6 denier, i.e., 40 Nc / 2 blending of 60% polyester and 40% scoured cotton yarn were twisted at 360 T / M to manufacture the first multi filament yarn of about 295.6 denier that can adjust the near infrared ray reflectance characteristics.

manufacturing example 4

[0068]A 40 Nc 1 blended yarn of polyester (60%) and scoured cotton yarn (40%) and a high flexible polyester filament yarn of about 150 denier were twisted at 360 T / M to manufacture the second multifilament yarn of about 282.8 denier without a component that can adjust the near infrared ray reflectance characteristics.

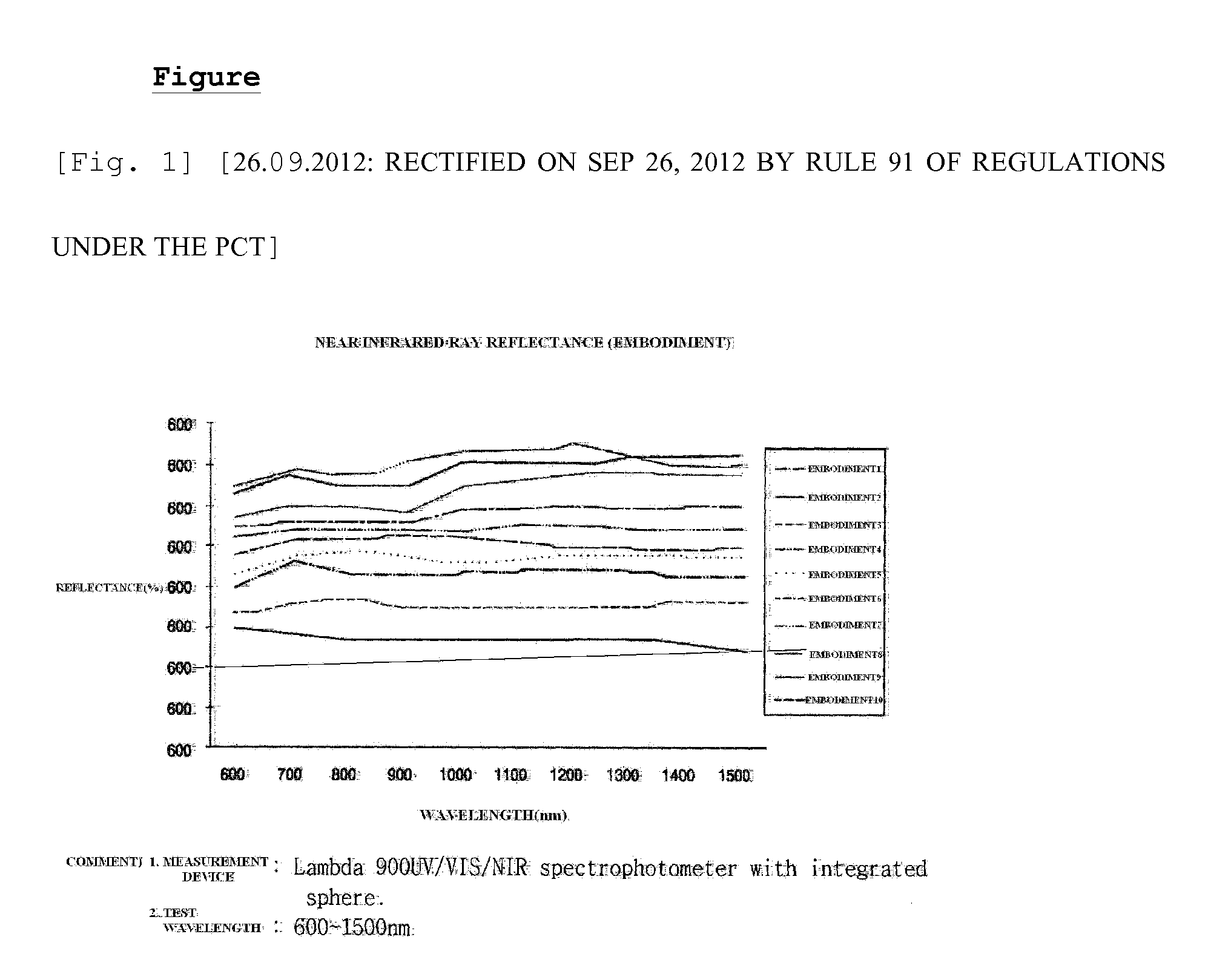

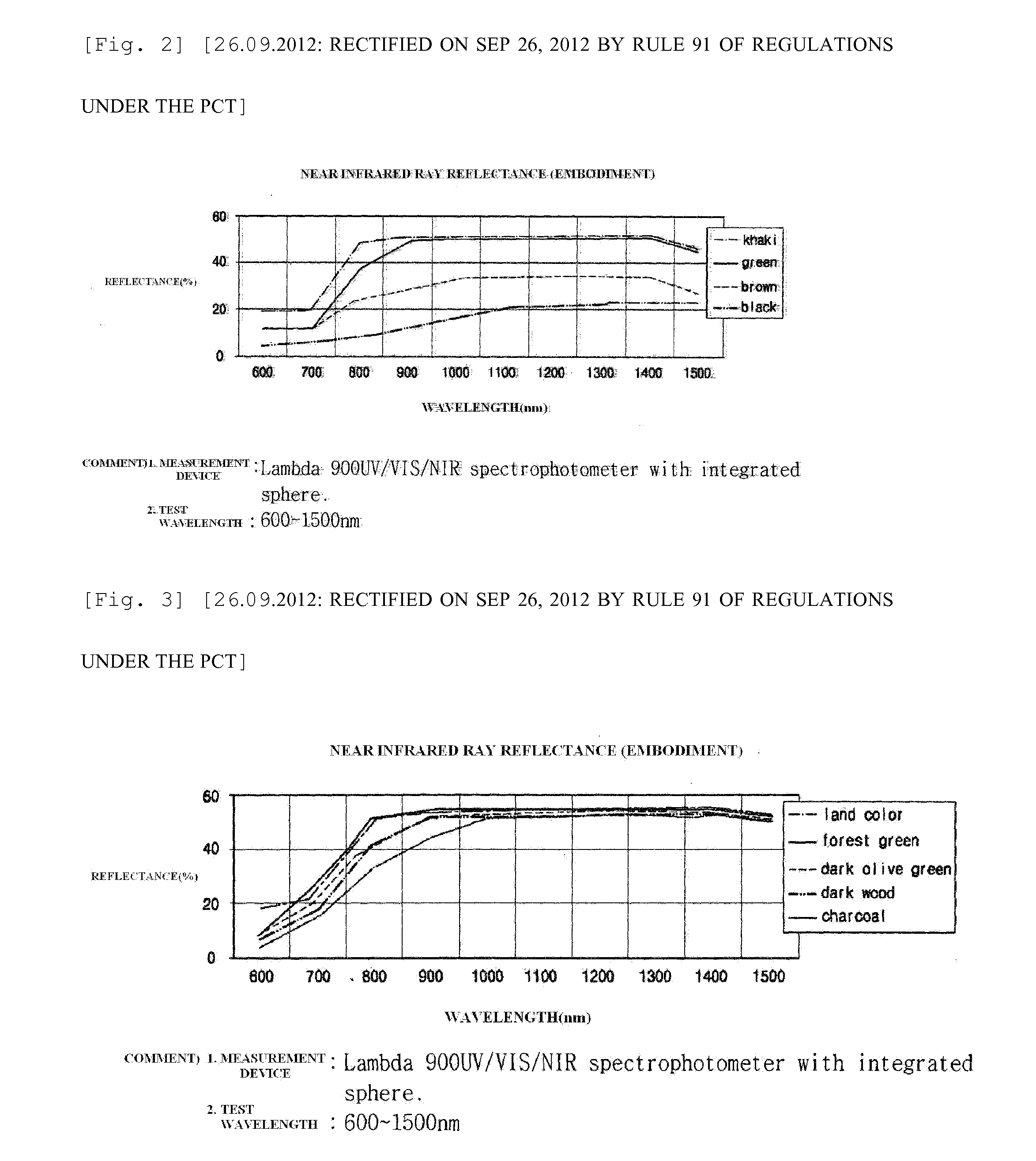

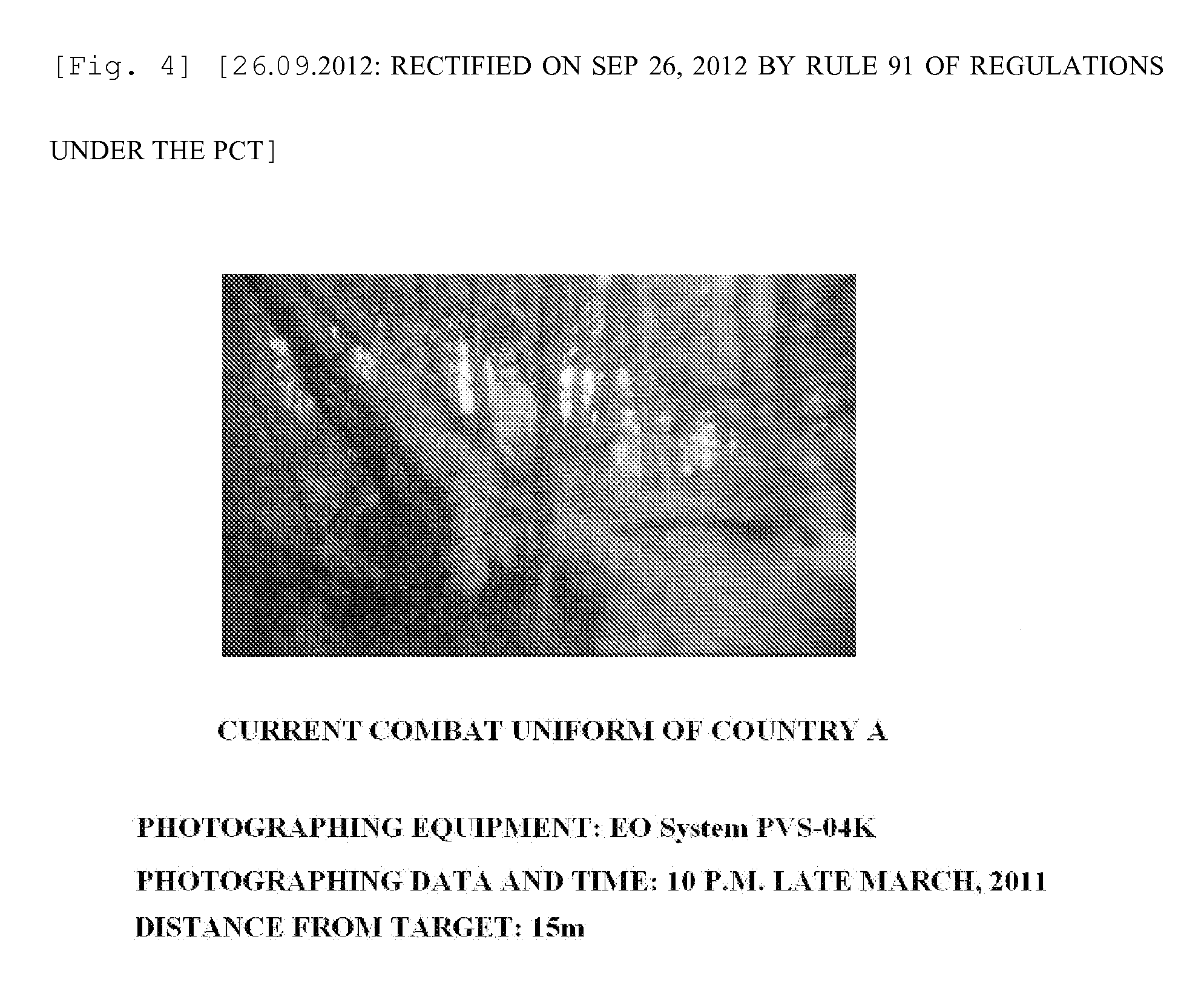

[0069]Hereinafter, various embodiments in which the first multifilament yarn of and the second multifilament yarn are designed into plain weaves or fancy plain weaves as a warp and a weft by a loom to variously control the near infrared ray reflectance will be described.

PUM

| Property | Measurement | Unit |

|---|---|---|

| near infrared ray reflectance | aaaaa | aaaaa |

| near infrared ray wavelength band | aaaaa | aaaaa |

| near infrared ray wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com