Process for preparing vilazodone hydrochloride

a technology of vilazodone and hydrochloride, which is applied in the field of preparing pharmacologically active substances, can solve the problems of difficult management of production systems, and inability to meet the needs of industrial production, etc., and achieves the effect of reducing the cost of vitride and reducing the cost of vilazodon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

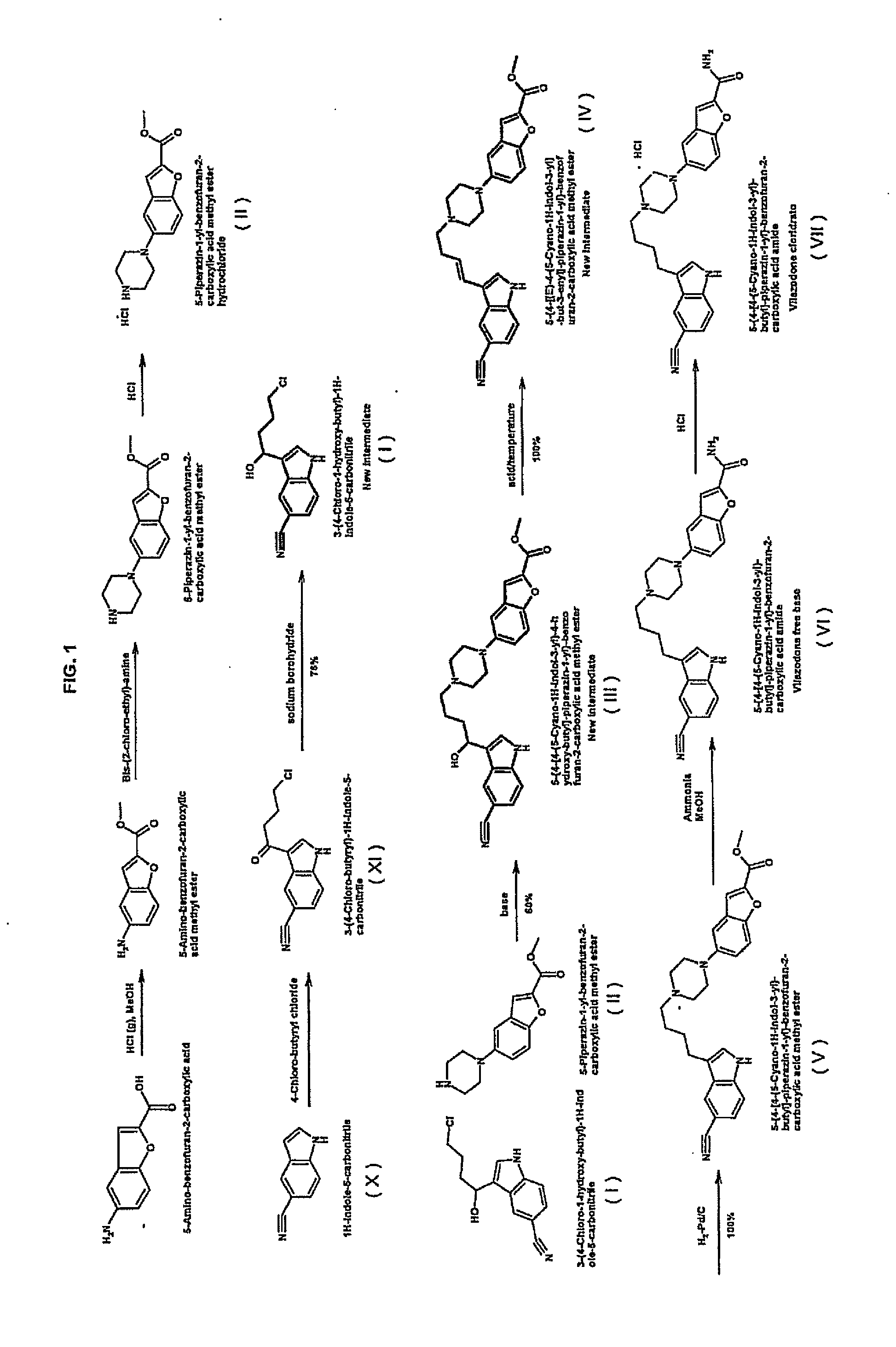

Method used

Image

Examples

example 1

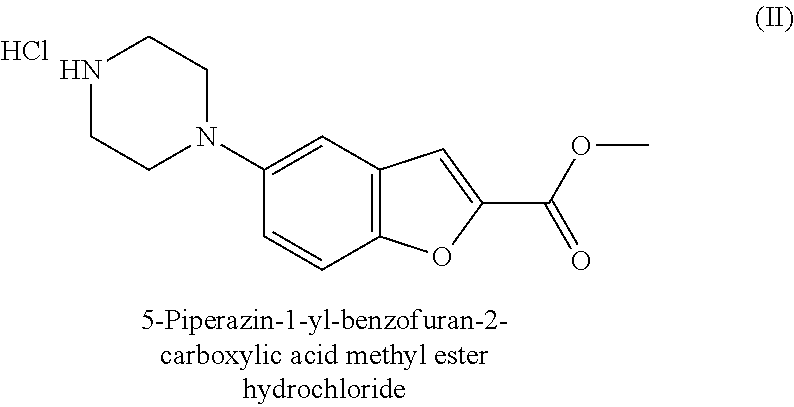

Process for preparing 5-Piperazin-1-yl-benzofuran-2-carboxylate methyl hydrochloride

Synthesis of 5-aminobenzofuran-2-carboxylic acid methyl ester

[0071]

Load into a flask:5-aminobenzofuran-2-carboxylic acid40 gMethanol200 g HCl gas10 gHeat the ground under reflux for 20 hours.Dry distil and add to the residueToluene40 gDistilled water200 g Ammonia 30%20 gStir under reflux until complete dissolutionCool at 5° C. until crystallization.Filter and wash with:Distilled water15 gDryThere are obtained 32.3 gYield 74.8%

Synthesis of 5-piperazin-1-yl-benzofuran-2-carboxylate methyl hydrochloride

[0072]

Load into a flask:5-Aminobenzofuran-2-carboxylic acid32 gmethyl esterBis-(2-chloroethyl)amine hydrochloride31.4 g Distilled water128 g Heat under reflux, then addSodium acetate43.2 g Stir then reflux for 1 hour then add at 30° C.Methylene chloride96 gAmmonia38.4 g Stir at 30° C., separate the organic phase,which is dry distilled under vacuum, then addto the residue:N,N-dimethylformamide80 gBubble...

example 2

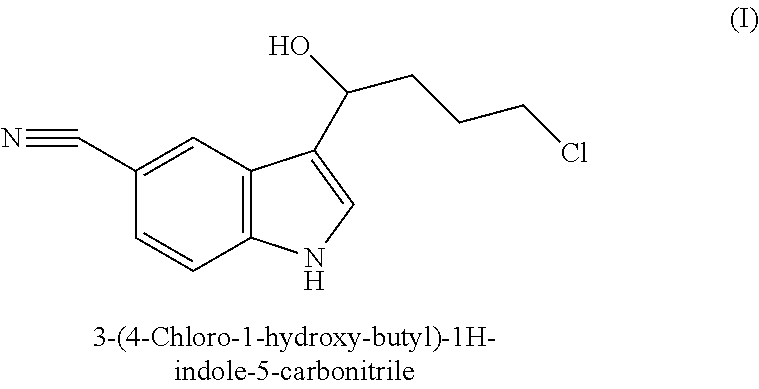

Process for preparing the intermediate 3-(4-Chloro-1-hydroxybutyl)-1H-indol-5-carbonitrile

Synthesis of 3-(4-Chlorobutyryl)-1H-indol-5-carbonitrile

[0073]

Load into a flask:Aluminium trichloride 93 gMethylene chloride320 gHeat under reflux, then add:4-chlorobutyryle chloride100 gWhile maintaining the reflux add aseparately prepared solution of:5-Cyano-indole 40 gMethylene chloride160 gStir at reflux for 30 minutes then pourthe reaction in a flask containingDistilled water400 gHydrochloric acid 32% 32 gOn completion of casting distil up to80° C. Add:Ethyl acetate200 gCool at 5° C., filter and wash with:Ethyl acetate 60 gDistilled water120 gDryThere are obtained 58 gYield: 83.6%

Synthesis of the intermediate compound 3-(4-Chloro-1-hydroxybutyl)-1H-indol-5-carbonitrile

[0074]

Load into a flask:3-(4-Chlorobutyryl)-1H-indol-5-carbonitrile58gTetrahydrofuran116gDistilled water11.6gHeat at 30-35° C., then add a separatelyprepared solution of:Distilled water.29g30% NaOH0.3gSodium borohydride7gStir...

example 3

Process for Preparing Vilazodone (Free Base / Hydrochloride

Synthesis of the intermediate 5-{4-[4-(5-Cyano-1H-indol-3-yl)-4-hydroxybutyl]-piperazin-1-yl}benzofuran-2-carboxylate methyl

[0075]

Load into a flask:5-Piperazin-1-yl-benzofuran-2-carboxylate11.9 g methyl hydrochlorideSodium bicarbonate6.7 g N,N-dimethylacetamide30 gPotassium iodide1.3 g 3-(4-Chloro-1-hydroxybutyl)-1H-indol-5-carbonitrile12 gHeat at 75° C. for 28 h then add:Distilled water50 gEthyl acetate50 gCool to 5° C., filter and wash with:Distilled water10 gDryThere are obtained 11 gYield 58%

Synthesis of the intermediate 5-{4-[4-(5-Cyano-1H-indol-3-yl)-but-3-enyl]-piperazin-1-yl}-benzofuran-2-carboxylate methyl

[0076]

Load into a flask:5-{4-[4-(5-Cyano-1H-indol-3-yl)-4-hydroxybutyl]- 3 gpiperazin-1-yl}-benzofuran-2-carboxylatemethylDMA15 gAmmonium chloride0.32 g Heat the mixture at 100° C. for 7 hoursCool to 20° C. then addEthyl acetate25 gAqueous solution of sodium bicarbonate 10%10 gStir and separate the organic phase, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com