Metal components with inert vapor phase coating on internal surfaces

a technology of metal components and internal surfaces, applied in the field of coating metal components, can solve the problems of difficult formation of peek into many required shapes and sizes of lc components, inability to readily obtain, and not as strong as metal mechanically

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Amorphous Si Coating

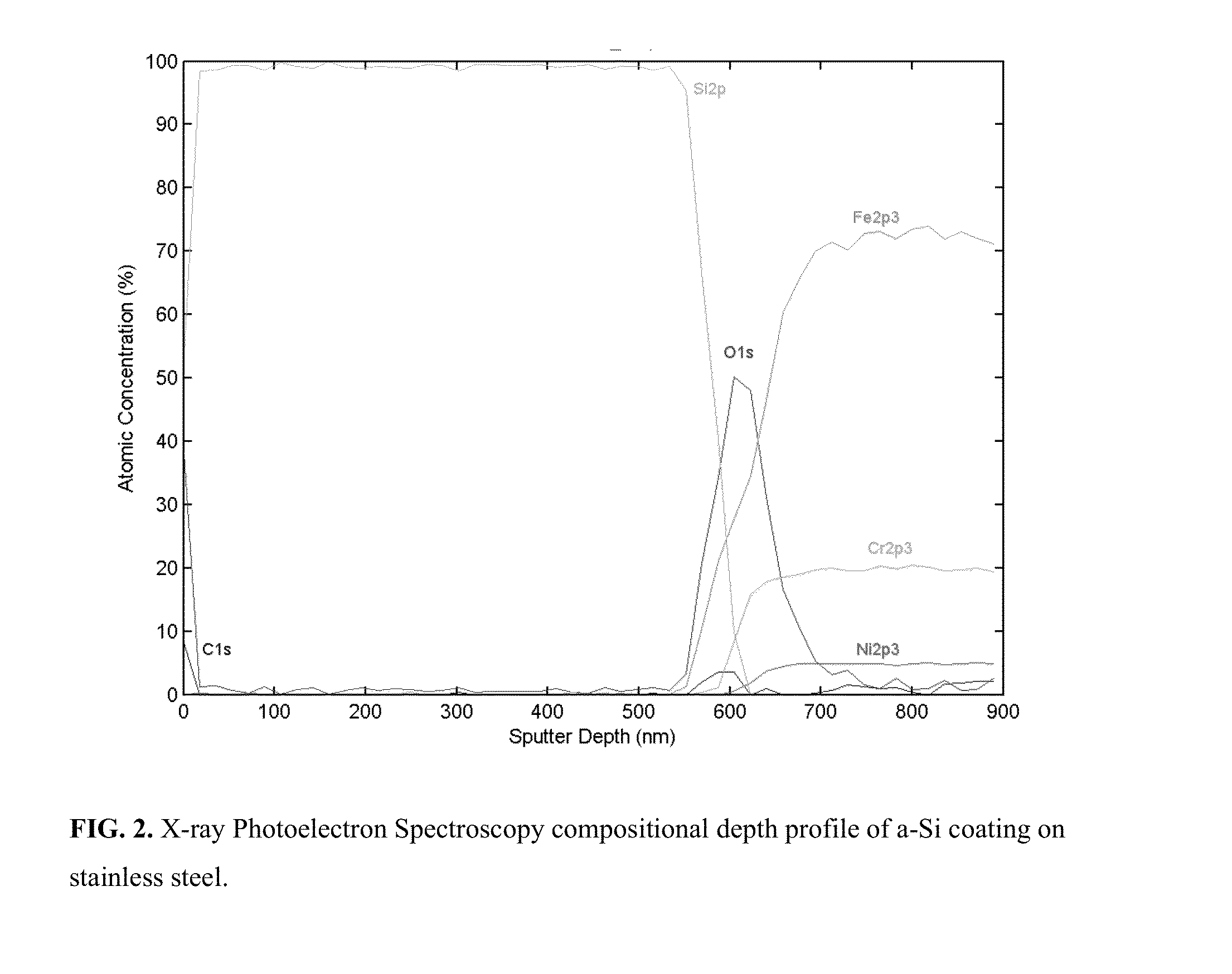

[0040]The first coating, an amorphous Si coating, was deposited on stainless steel coupons, frits and HPLC columns, and on titanium coupons. Deposition was done by thermal chemical vapor deposition in a closed reactor using SiH4 gas as a molecular precursor. Temperature for deposition was between 350° C. and 450° C. and partial pressure of SiH4 in the reactor was between 50-1000 mbar in dry nitrogen gas. Two depositions were done in succession to achieve a coating thickness of 550 nm on coupons and 100 nm in the interior of the HPLC column. Coating thickness on the coupons was measured using spectral reflectance and verified by X-ray Photoelectron Spectroscopy. Coating thickness on the column interior was estimated from the relative intensities of the

[0041]Fe K series and Si K series lines from Energy Dispersive X-ray Spectroscopy, compared to relative intensities on flat surfaces with known a-Si thickness. Thickness of the coating on titanium coupons, deposited ...

example 2

Polymeric Siloxane Coating

[0044]The second coating, a polymeric siloxane coating, was deposited using chemical vapor deposition at a temperature between 350° C. and 450° C. Coating thicknesses of 100 nm to 300 nm were achieved on stainless steel coupons, stainless steel fits, and on the interior surface of HPLC columns. All parts demonstrated greater than 10× reduction in metal ion concentration released into solution when soaked in 0.1% formic acid. In addition, a siloxane coated HPLC column was packed with silica beads held in place by two siloxane-coated frits. This column showed superior performance to a stainless steel column with stainless steel frits in a liquid chromatography separation of Cytochrome C, an enzyme known to be sensitive to metal ions.

example 3

Bilayer Coating (Si / Siloxane)

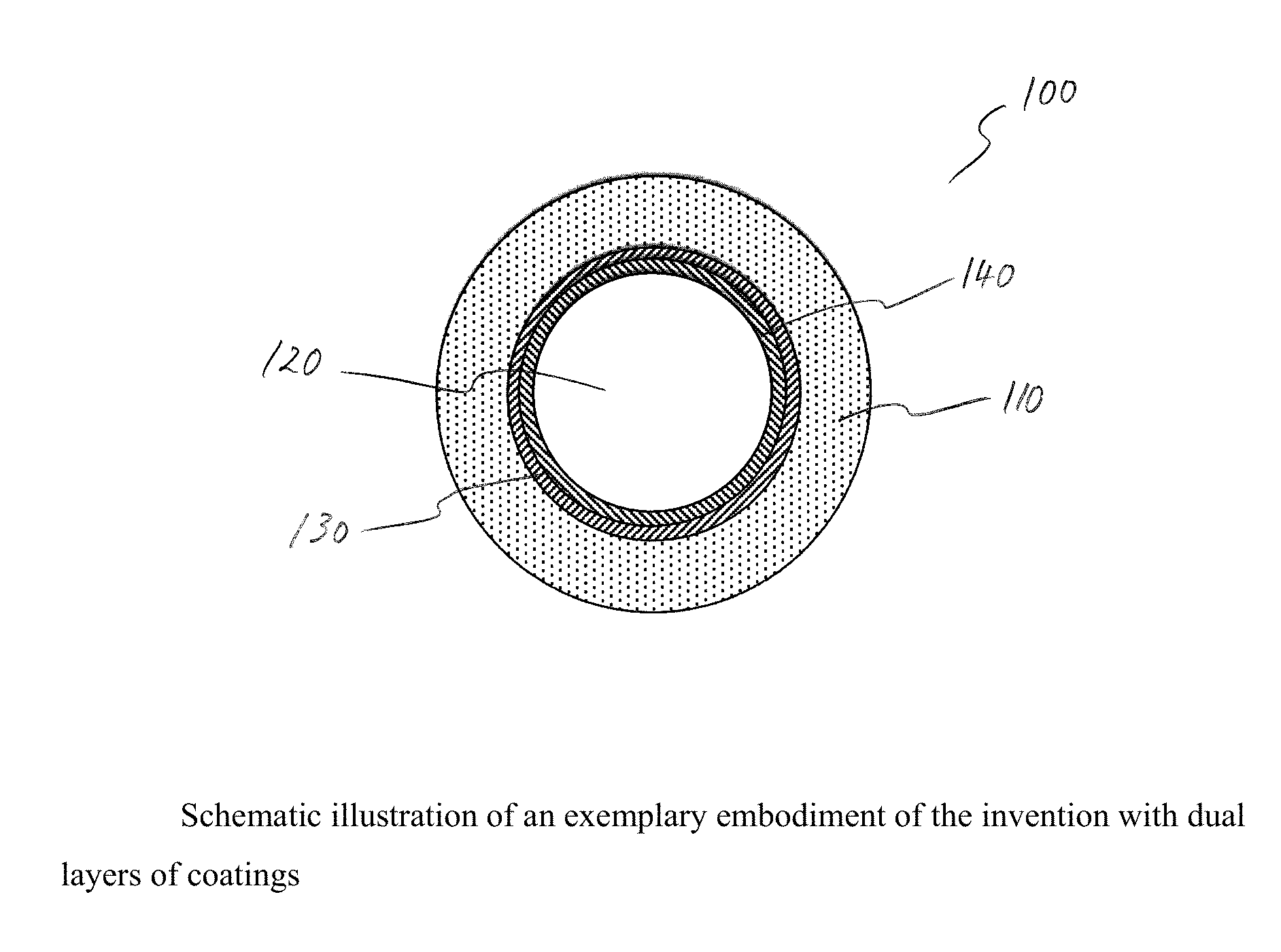

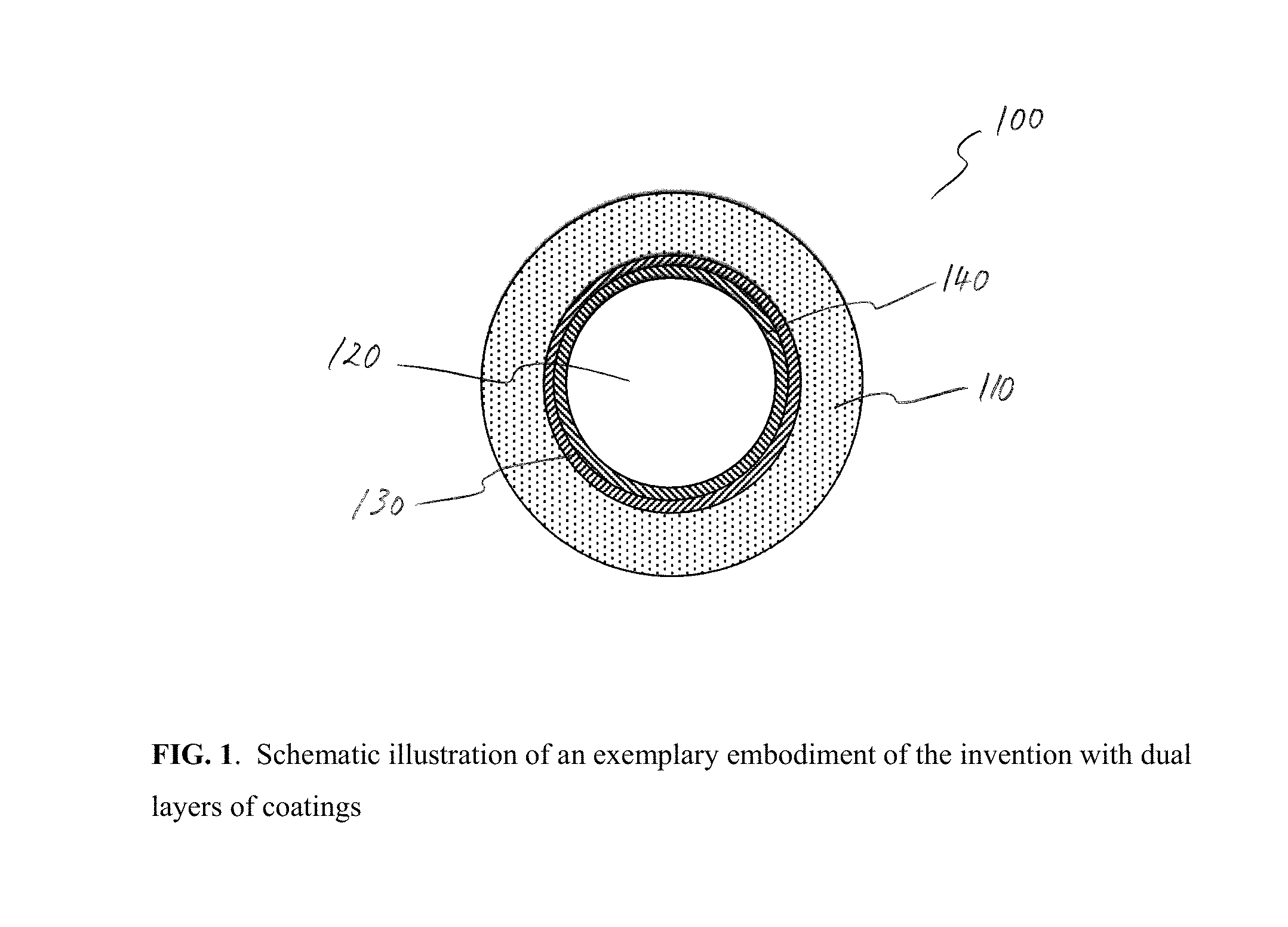

[0045]The third coating was a bilayer consisting of 200 nm of a-Si directly on the stainless steel, covered by 150 nm of siloxane coating on the a-Si. This coating was deposited by the above described chemical vapor deposition processes on stainless steel coupons. These coupons demonstrated 10X reduction in metal ion concentration after soaking in 0.1% formic acid. A similar bilayer was also deposited on the interior surface of an HPLC column and demonstrated a superior liquid chromatography separation of Cytochrome C compared to a stainless steel column.

[0046]FIG. 3 shows comparison of ions leached into solution from 2×3 cm stainless steel coupons coated with a-Si, siloxane, and Si / Siloxane bilayer compared to ions leached from uncoated stainless steel. Coupons were soaked in 0.1% formic acid at 50C for four days. Metal ion concentration in solution measured by Inductively Coupled Plasma-Mass Spectrometry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com